S&S Cycle Sidewinder 3 5⁄8 Big Bore Cylinders for Harley-Davidson Sportster Models—1986–2003 User Manual

Page 8

8

D. With key in shaft, insert into respective tapered hole in flywheel and check to see that key does not bottom in groove. If key bottoms

out, file flat side of key, not rounded side, until shaft with key in place fits in flywheel without bottoming out. Check crankpin and

crankpin key also.

E. Reclean mainshaft tapers, crankpin and flywheel tapers with lacquer thinner.

F. Assemble mainshafts in respective flywheels. Coat taper and threads of each shaft with green Loctite® during assembly. Install crankpin

in camside flywheel using Loctite® also. Tighten crankpin nuts to 290–310 ft. lbs. Tighten pinion and sprocket shaft nuts to 340–360 ft.

lbs.

G. After camside flywheel, pinion shaft, and crankpin are assembled, blow air through pinion shaft oil feed hole to check for blockage or

misalignment of oil feed passages.

Partially or completely blocked oil feed passageways may cause irreversible damage to connecting rod bearings and other engine

components.

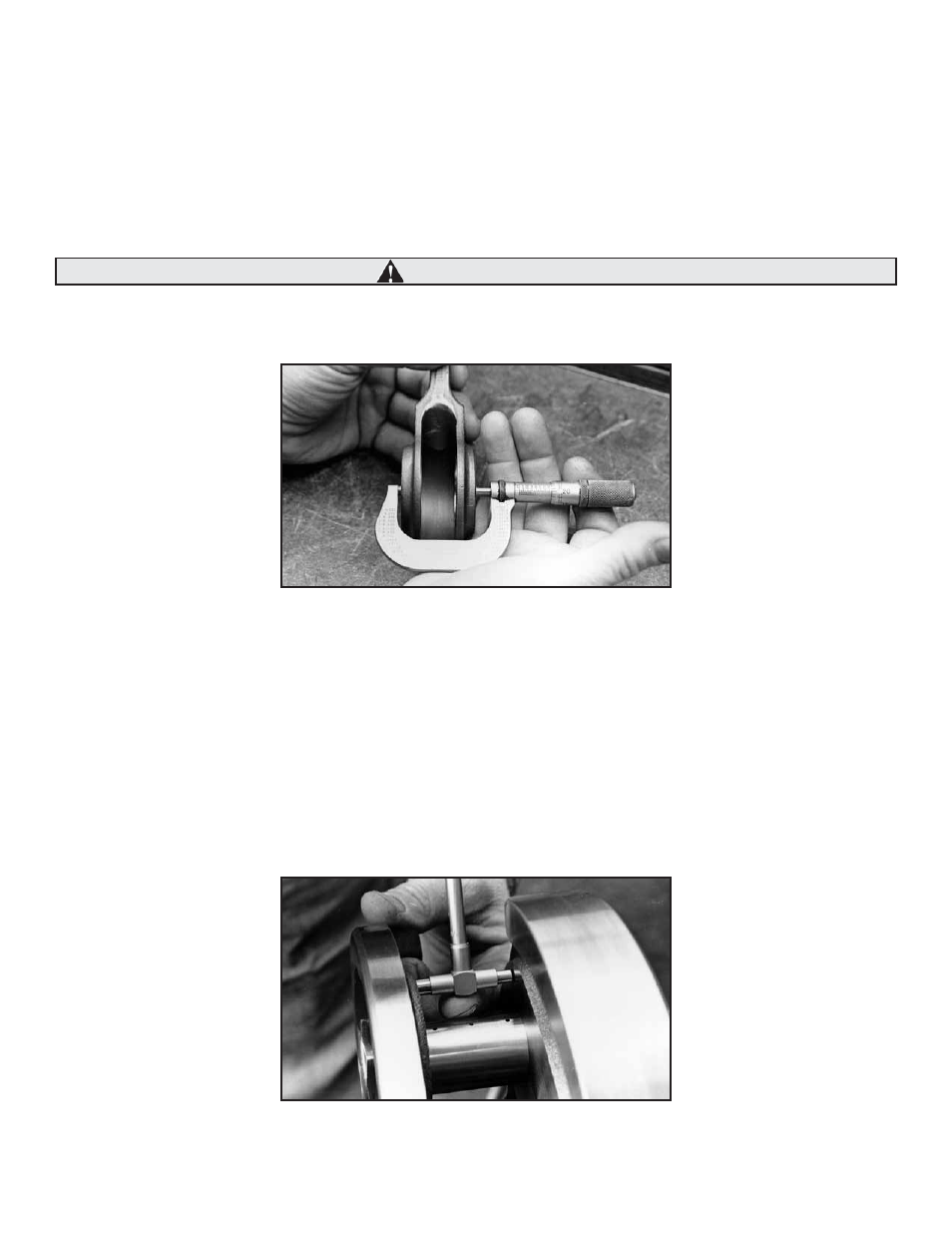

H. Measure width of female rod on crankpin end. See Picture 7, below. Measurement should be 1.481" to 1.483".

I. A pre-assembly connecting rod side play check should be done before final assembly to determine if connecting rod side play will fall

within the specified .015"–.035" range when crankpin nuts are final tightened. Assemble left and right flywheels on crankpin without

rods. Moderately snug crankpin nuts. Do not worry about flywheels being true. Measure distance between connecting rod thrust

pads on flywheels. See Picture 8, below. Rod side play will be reduced by about .015" when crankpin nut is final tightened. Therefore,

distance between flywheel thrust pads as measured in this check must be .030"–.050" greater than female rod width measured in Step

H. For example, if female rod measures 1.482", the distance between flywheel pads must be 1.512"–1.532". If difference between pad to

pad distance and female rod width is less than .030", female rod must be surface ground on sides to provide more clearance. Take equal

amounts off each side if more than .010" is to be removed. If more than .050” must be removed from female rod width or if difference

between pad to pad distance and female rod width is greater than .050" a different crankpin should be tried. If there is too little or too

much connecting rod side play, and different crankpins do not correct problem, contact S&S®.

NOTE: S&S recommended rod side play is .015" to .035". If material is removed from sides of female rod, overall width of bearing cages must be reduced

so bearings and cages are free to float with rods without contacting flywheel thrust pads. Bearing cage side clearance of .008" to .020" less than

rod width is recommended.

Picture 8

Picture 7

CAUTION