S&S Cycle Sidewinder 3 5⁄8 Big Bore Cylinders for Harley-Davidson Sportster Models—1986–2003 User Manual

Page 6

6

5. Modify Crankcases for Oil Returning from Heads

NOTE: Oil return passageways in Sidewinder® cylinders are moved out slightly compared with stock oil return holes to accommodate 35⁄8" bore. This

creates misalignment between cylinder oil return passage and crankcase oil return passage.

To modify cases and return oil properly, perform following steps:

A. Place cylinder base gasket on cases and note amount and direction of return hole mismatch.

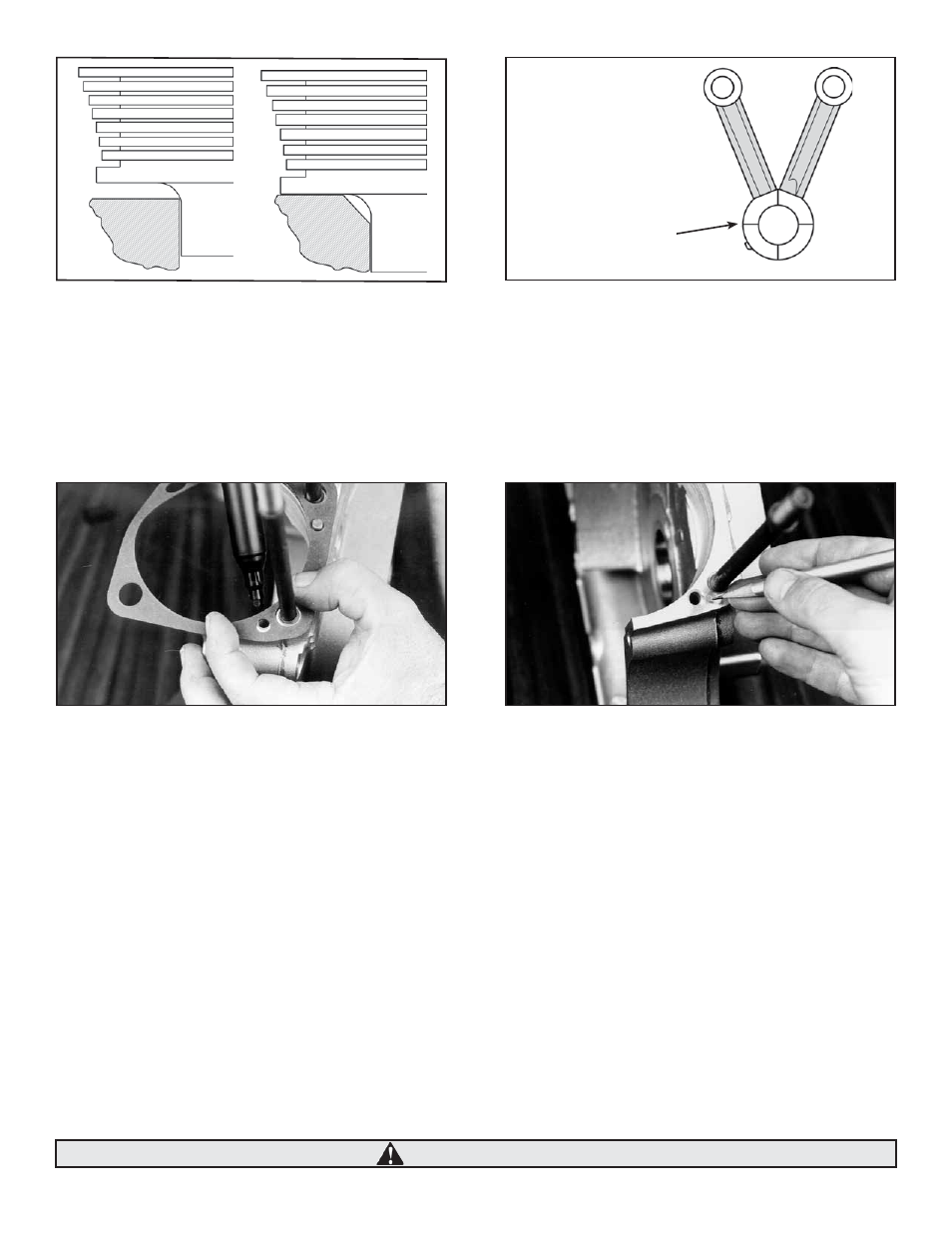

B. Chamfer edge of hole accordingly at minimum of 45° angle to insure adequate flow. See Pictures 5, below left, and 6, below right..

6. Convert Pinion Main Bearing

To 1987 & Later Style (1986 crankcases only)

A. Remove stock Torrington® style pinion needle bearing assembly. Follow procedures outlined in 1986 Harley-Davidson® service manual for

removal.

B. Install 1987 and later style pinion bearing race H-D® #8881. Follow procedures outlined in 1987 and later Harley-Davidson® service manual.

C. Lap bearing race and fit bearings per procedures outlined in 1987 and later Harley-Davidson® service manual.

All reference to Harley-Davidson® part numbers is for identification purposes only. We in no way are implying that any of S&S® Cycle’s products are

original equipment parts or that they are equivalent to the corresponding Harley-Davidson® part number shown.

7. Connecting Rod Preparation (79" kits only)

NOTE: If S&S® connecting rods are used, follow instructions that accompany rods since rod preparation below has already been done. Stock rods can not

be used with Sidewinder kits larger than 79". Longer than stock S&S connecting rods will be provided with all kits larger than 79".

79" kit 91-3002 only—If S&S rods are not used, perform following steps:

A. To insure adequate oil on sides of rods and matching thrust surfaces of flywheels, S&S recommends that four grooves be ground on each

side of both front and rear connecting rods. See Figure 2, above right. Make these grooves .020" to .030" deep and .030" to .040" wide

and should be ground 90° from each other. After making grooves, remove all sharp edges and burrs with emery cloth.

B. Thoroughly clean all parts to remove dirt, filings, etc.

Burrs, dirt, filings, etc. left on connecting rod components may circulate in oil damaging other parts possibly causing engine failure.

CAUTION

Figure 1

Figure 2

Grind four (4) oil groves

on both sides of forked rod

Picture 5

Picture 6