S&S Cycle Sidewinder 3 5⁄8 Big Bore Cylinders for Harley-Davidson Sportster Models—1986–2003 User Manual

Page 4

4

E. Place cases squarely in mill. Base gasket surface must be square with center line of crankshaft and 45° from opposite cylinder base gasket

surface. Machine gasket surface taking minimum necessary to clean surface. Repeat for other cylinder.

F. Reinstall cylinder studs. For engines under 96" (45⁄8" stroke) reinstall original studs. For engines of 96" or larger install late big twin style

studs. (See Step 3) Consult Harley-Davidson® service manual for proper stud installation procedure.

3. Cylinder Mounting Studs—96" Engines and Larger only

NOTE: S&S Sidewinder kits for Evolution® Sportster® models of 96" (45⁄8" stroke) or greater require the use of big twin cylinder studs. This is due to the

increased cylinder length in these kits.

A. Remove stock cylinder studs if this has not been done in Step 2. Consult Harley-Davidson® service manual for proper stud removal

procedures.

Be careful when removing studs so as not to damage threads in cases. If stud does not come out easily, carefully heat case around stud

as heat may help loosen threads. Do not allow crankcase temperature to exceed 375° F, as this may destroy heat treatment of crankcase

material.

B. Install late big twin male type studs, S&S 31-2321, or Harley-Davidson® part #16837-85C. Consult Harley-Davidson® service manual for

proper installation procedures.

4. Bore Crankcases

NOTE: Boring cylinder spigot holes in cases to accommodate big bore cylinders will machine a notch on center case bolt. This bolt must be replaced with

a special stud which is installed into the top crankcase bolt hole in the cam side case half.

Perform following procedure to bore crankcases:

A. In 1986–1990, four speed cases, the center crankcase bolt must be replaced by S&S® stud 31-2046. In 1991 and later, 5 speed cases, the

center crankcase bolt must be replaced by S&S stud 31-2047. The stud will be installed in the threaded hole in the camside crankcase

half that the stock center crankcase bolt normally screws into.

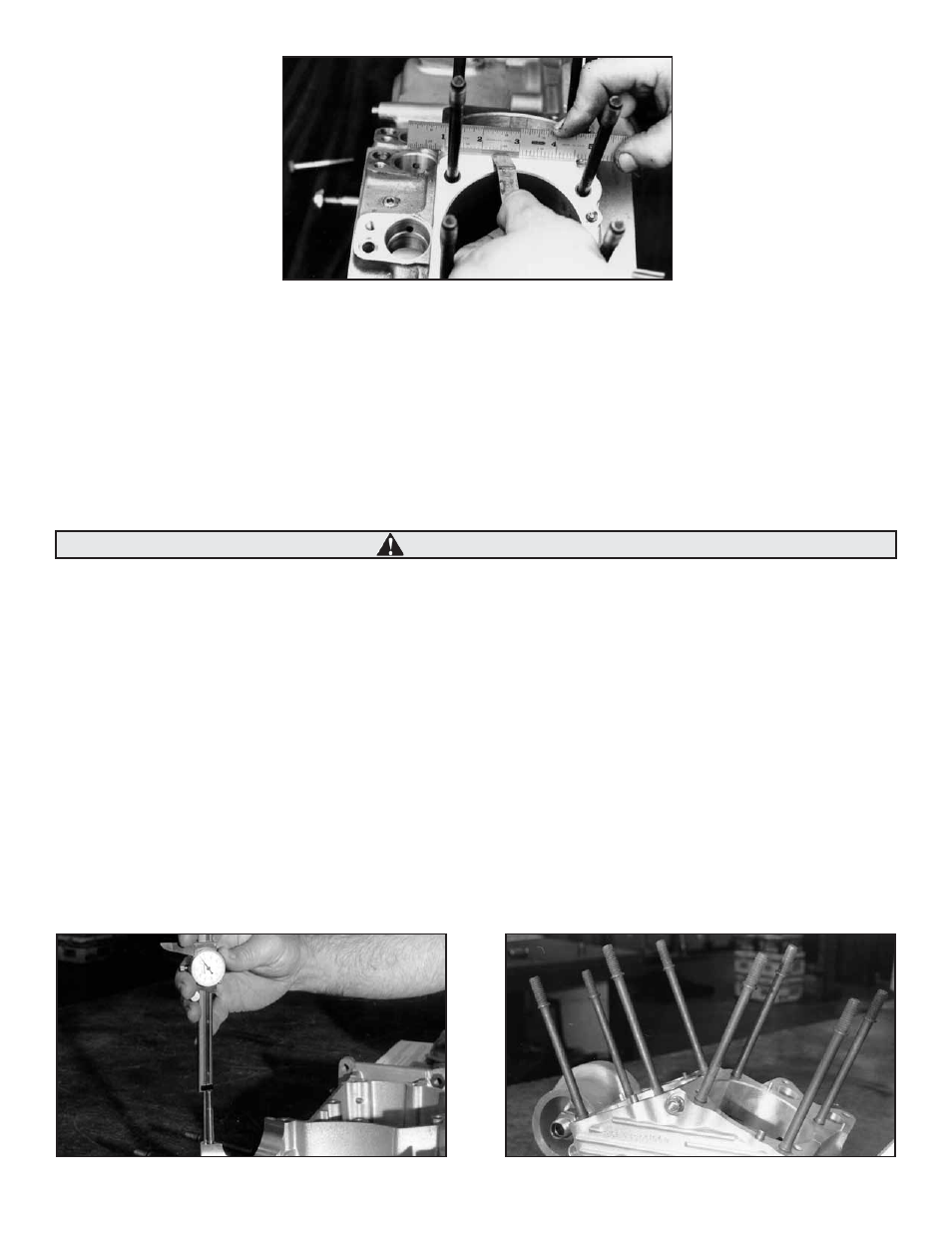

1. Before final installation of stud, screw stud into hole to make sure installed height is correct. See Picture 2, below left. Stud should

extend 2.570"–2.630" from crankcase to top of stud for 1986–1990 crankcases, and 2.270"–2.330" from crankcase to top of stud for

1991 and later crankcases. If driveside case is set in place, stud should extend far enough that there is full thread engagement with 12

point nut 50-5024 when washer is in place. See Picture 3, below right.

Picture 1

Picture 2

Picture 3

CAUTION