S&S Cycle Sidewinder 3 5⁄8 Big Bore Cylinders for Harley-Davidson Sportster Models—1986–2003 User Manual

Page 13

13

12. Piston to Head & Piston to Valve Clearancing

NOTES:

• The clearancing operations described in this section can be done simultaneously as the same set-ups are used. Please read this entire section before

beginning work.

• All valve spring spacing, rocker arm to collar and rocker arm to rocker cover clearancing must be done before piston to valve clearancing can be

checked.

• S&S® flat topped pistons have sufficient valve clearance when used with most street high performance cams with lifts up to .525". However, we

recommend that valve clearancing be checked if other than stock cam is used.

• If S&S cylinder heads and pistons are used, cams of up to .560" lift can be run without valve to piston clearance problems. If cams with higher lift are

used this clearance must be checked.

Improper installation of pistons may cause unwarranted stress, premature wear and/or contact with each other or other engine

components resulting in damage to pistons or other engine parts.

• If there is any resistance or contact at any point in rotation it must be diagnosed and corrected. Since it is nearly impossible to anticipate every

possible engine combination, it is the engine builder’s responsibility to check for proper running clearances. S&S considers checking and establishing

all running clearances as standard engine building practice that must be performed during engine assembly. Engine failure due to improper

clearances between moving parts is not covered under warranty.

Contact between moving engine components may cause damage or destruction of the parts involved and produce abrasive particles

which may cause damage or premature wear to other engine components.

A. Piston to head (squish) clearance

1. Assemble engine with exception of cylinder heads.

NOTE: Pinion Shafts included with S&S flywheels kits and assemblies for Evolution® Sportster® models are of the 1987 type. This means that 1986

crankcases must be converted to use the 1987 and later style caged roller pinion main bearing assembly, and that 1986–1987 style pinion gear

and oil pump drive gears must be used in 1988 and later engines. See step 6.

2. Rotate flywheels so front piston is positioned at top dead center.

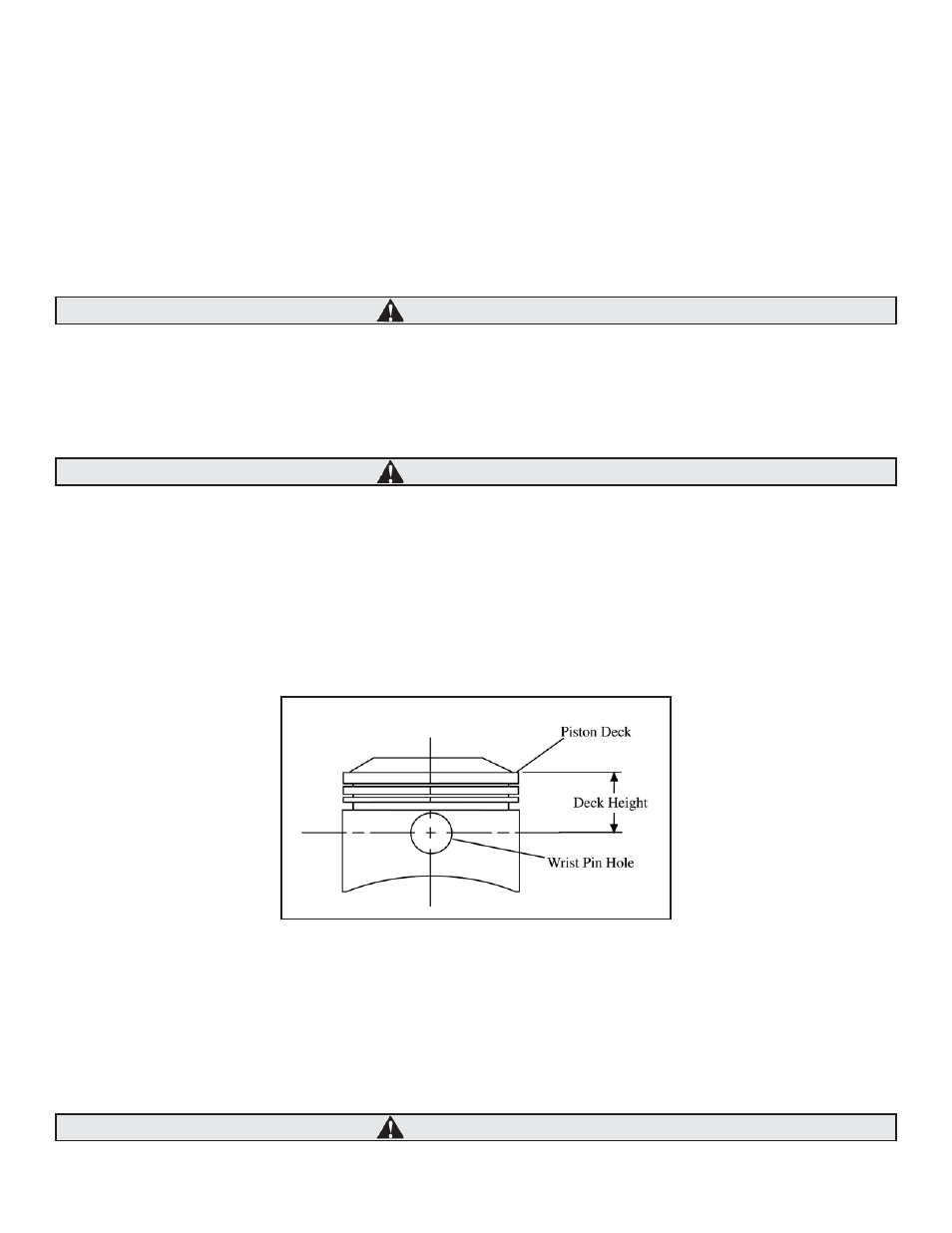

3. Note where piston deck (See Figure 5, piston deck diagram) is positioned in relationship to head gasket surface. Piston deck (flat

located just above top compression ring groove), not dome, must be flush with or slightly below gasket surface.

4. If piston deck is higher than cylinder at top dead center, something is wrong and S&S should be notified. If piston deck position is

correct proceed to Step B.

NOTE: Most stock V-Twin and S&S engines are designed with .045" to .062" piston to head clearance. This clearance is provided by thickness of head

gasket. Therefore at top dead center, piston deck should be flush with or slightly below head gasket surface of cylinder. Cylinder base gasket must

be in place when this check is made.

Insufficient clearance between piston domes and cylinder heads will cause damage to pistons and heads.

Figure 5

CAUTION

CAUTION

CAUTION