1top view – S&S Cycle Sidewinder 3 5⁄8 Big Bore Cylinders for Harley-Davidson Sportster Models—1986–2003 User Manual

Page 15

15

C. Install pistons, rings and wristpin clips per S&S piston instruction sheet 51-1028.

D. Coat piston skirts with engine oil or assembly lube and install cylinders.

E. Place o-ring seals over cylinder head alignment dowels. Install head gaskets provided in kit dry.

NOTE: Care must be taken to use correct alignment dowel o-rings with 1986 and later Sportster® models head gaskets. Head gaskets supplied with S&S

cylinder heads compress to about .045” thick and require .070" diameter o-rings. Gaskets supplied with Sidewinder® for stock heads compress to

about .0625" and require .0825" diameter o-rings.

Using thin o-rings with thick gaskets or thick o-rings with thin gaskets may cause oil leaks or possible ruptured head gaskets around

line-up dowels due to incorrect o-ring compression.

NOTE: All S&S cylinder head kits are supplied with .045” thick head gaskets, because this clearance promotes better combustion chamber turbulence

and flame travel. When other cylinder heads are used S&S supplies .0625" thick gaskets. Using thicker head gaskets with S&S heads reduces design

efficiency and performance. If thinner head gaskets are used with other cylinder heads, piston to head and valve to piston clearances must be

checked during assembly.

Insufficient clearance between piston domes and cylinder heads or piston domes and valves will cause damage to pistons, heads and/

or valves.

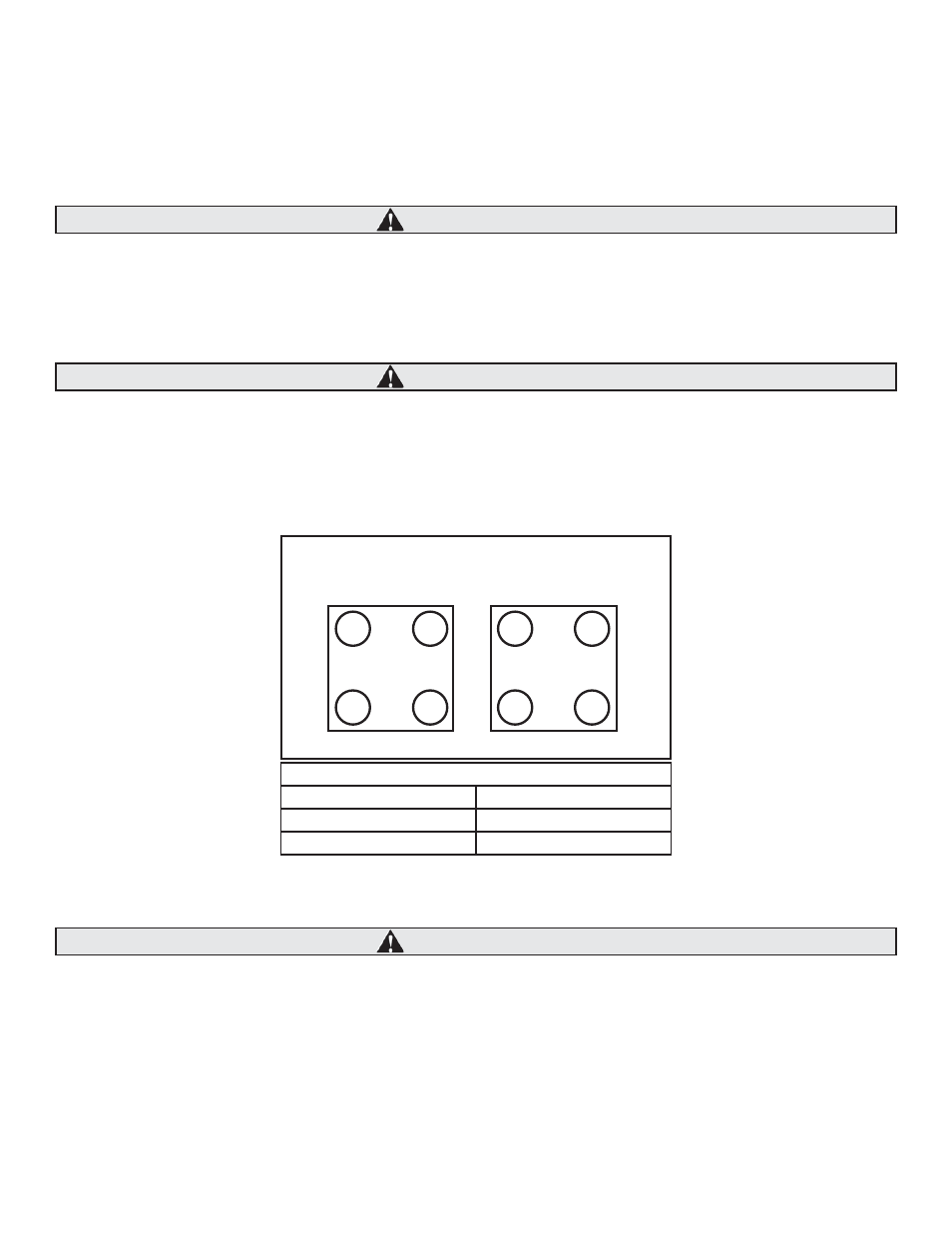

F. Bolt heads on cylinders. Place one or two drops of oil on threads of each head bolt just prior to final assembly to reduce friction and

insure accurate torque readings. Tighten bolts in stages using crossing pattern. See Figure 6. If using S&S crankcases, torque bolts to

45-47 ft. lbs. in four stages. If using stock crankcases, follow the same bolt tightening sequence, but use stock three stage procedure and

torque values shown in Figure 6. If using other aftermarket crankcases, contact the manufacturer for recommended head bolt torque

specifications.

NOTE: Light coating of oil on head bolt threads minimizes friction so torque values are not distorted. It cannot be emphasized enough how important it

is to do these steps carefully. Maintaining a good head gasket seal depends on it.

Improper torquing sequence and head bolt torque values may cause head gasket failure. Excessive torque values may cause studs to

pull out of crankcase.

G. Finish Assembling Top End

1. Install rocker arm bases per Harley-Davidson® specs.

2. 1991 and later five speed models only—Stock one piece pushrod tube assemblies on 1991 and later five speed engines must be

replaced with 1986 to 1990 style two piece pushrod tubes to allow adjustment of pushrods. Installation of 33-5360 S&S® pushrod tube

adapter provides cup for bottom of earlier style pushrod tubes. Place stock pushrod retainer over small end of adapter. Slide stock

pushrod seal on small end of adapter. Install adapter, retainer, and seal over tappet bore in crankcase with stock bolt and washer. Do

not final tighten. See Picture 16, next page.

CAUTION

CAUTION

CAUTION

1

Top View

Driveside

Camside

3

3

4

4

1

2

2

Figure 6

S&S® Crankcase

Stage 1

7–9 Ft. Lbs.

Stage 2

12–14 Ft. Lbs.

Stage 3

Turn additional 90°