S&S Cycle Sidewinder 3 5⁄8 Big Bore Cylinders for Harley-Davidson Sportster Models—1986–2003 User Manual

Page 5

5

2. If stud can not be screwed in far enough to obtain specified stud height, hole must be drilled and tapped deeper. It is recommended

that this drilling operation be done on a milling machine or drill press to avoid destroying existing threads.

3. If stud can be installed to correct height, clean stud and threaded hole with lacquer thinner and install stud to correct height using

red Loctite® or other permanent thread locking compound.

B. Clean cases thoroughly and assemble using all case bolts. Tighten all case bolts as in final assembly.

C. Place masking tape over both ends of camshaft and mainshaft bearings to keep chips out.

D. Bolt boring plate to bench or stand leaving squared end of plate protrude over edge approximately 7".

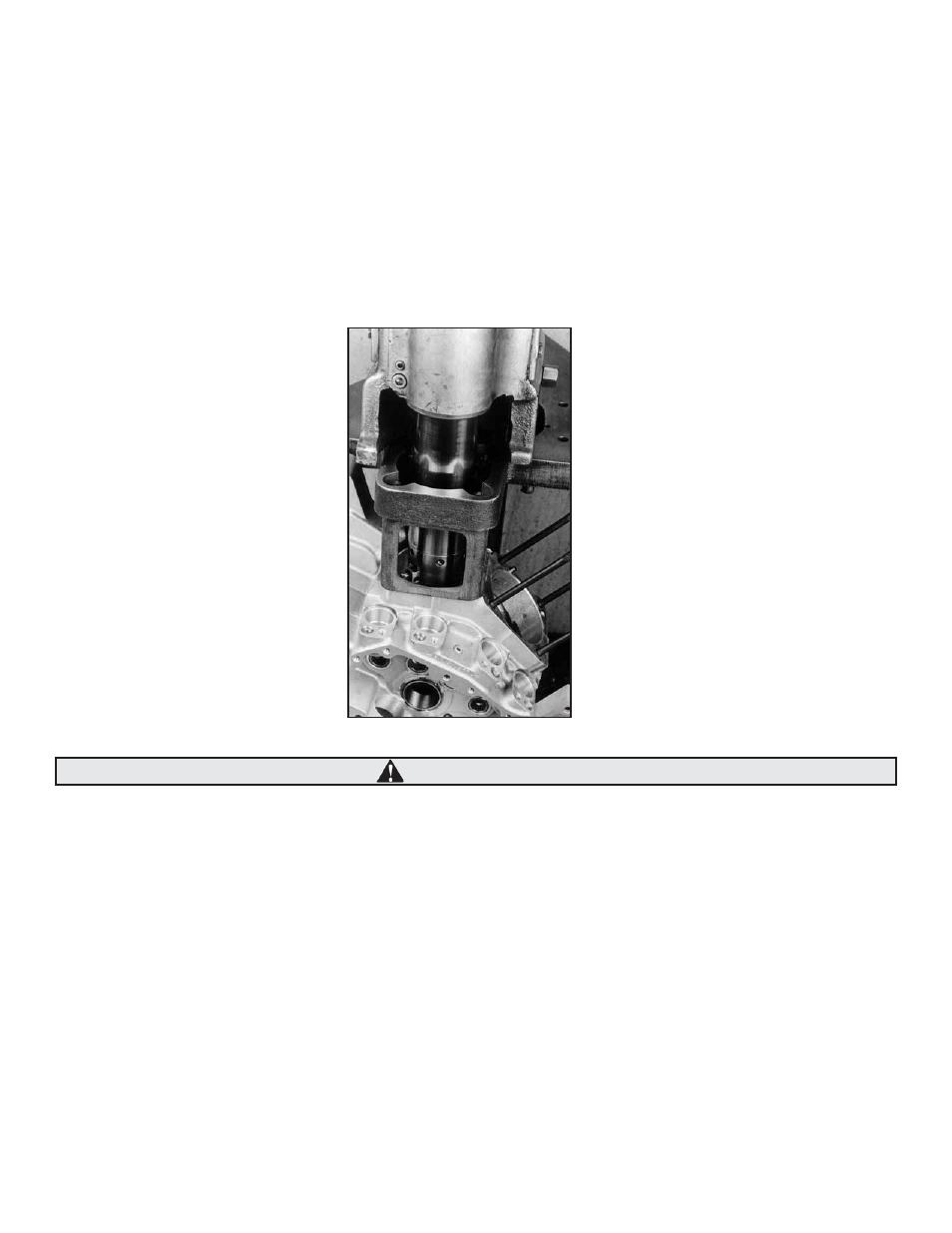

E. Using 43⁄8 -16 thread nuts, bolt cases to plate using all four studs. Boring spacer, Part 53-0007, is used to space cases using stock Harley-

Davidson® Sportster® models studs. If Sportster® model studs have been replaced with late, male style big twin studs, use both 53-0007

and53-0008 spacers to space cases away from boring fixture. See Picture 4, below.

NOTE: Be careful not to damage studs. Do not lift cases by studs and avoid knicking, scratching or denting studs.

Damaged studs may cause stress risers which can lead to stud failure and possible damage to engine components.

F. Center boring bar head in cylinder spigot bore in crankcases, not hole in plate. Refer to manufacturer’s instructions supplied with

boring bar for correct procedure.

G. Bore hole to diameter of 3.878" to 3.880" by 15⁄8" deep. Measure depth perpendicular from cylinder base gasket surface.

NOTE: We normally take three cuts to bore cases, 3.800" diameter, 3.850" and final size 3.879". If you machine into boring plate on final cut, this is of no

consequence since hole in plate is never used as machining reference point.

H. Repeat steps E to G for other spigot bore.

I. Deburr and remove any nubs or protrusions which could accidentally break off. Break the corner on outside of spigot holes with a

deburring tool. This insures that cylinder will not hang up during installation causing oil leaks due to inadequate gasket compression.

Figure 1, next page top left, shows an exaggerated view.

Picture 4

CAUTION