S&S Cycle Sidewinder 3 5⁄8 Big Bore Cylinders for Harley-Davidson Sportster Models—1986–2003 User Manual

Page 16

16

3. Assemble rocker arms, pushrods and pushrod tube assemblies and adjust pushrods. For 1991 and later five speed motors, place bottom

end of 1986 to 1990 pushrod tubes in cup of adapter. Use stock 1986 to 1990 pushrod seals. Rotate S&S pushrod tube adapters so that

cup surface is as close to perpendicular with pushrod tube as possible. Install pushrod cover clip and final tighten stock pushrod tube

retainer bolt.

4. Install rocker covers and gaskets.

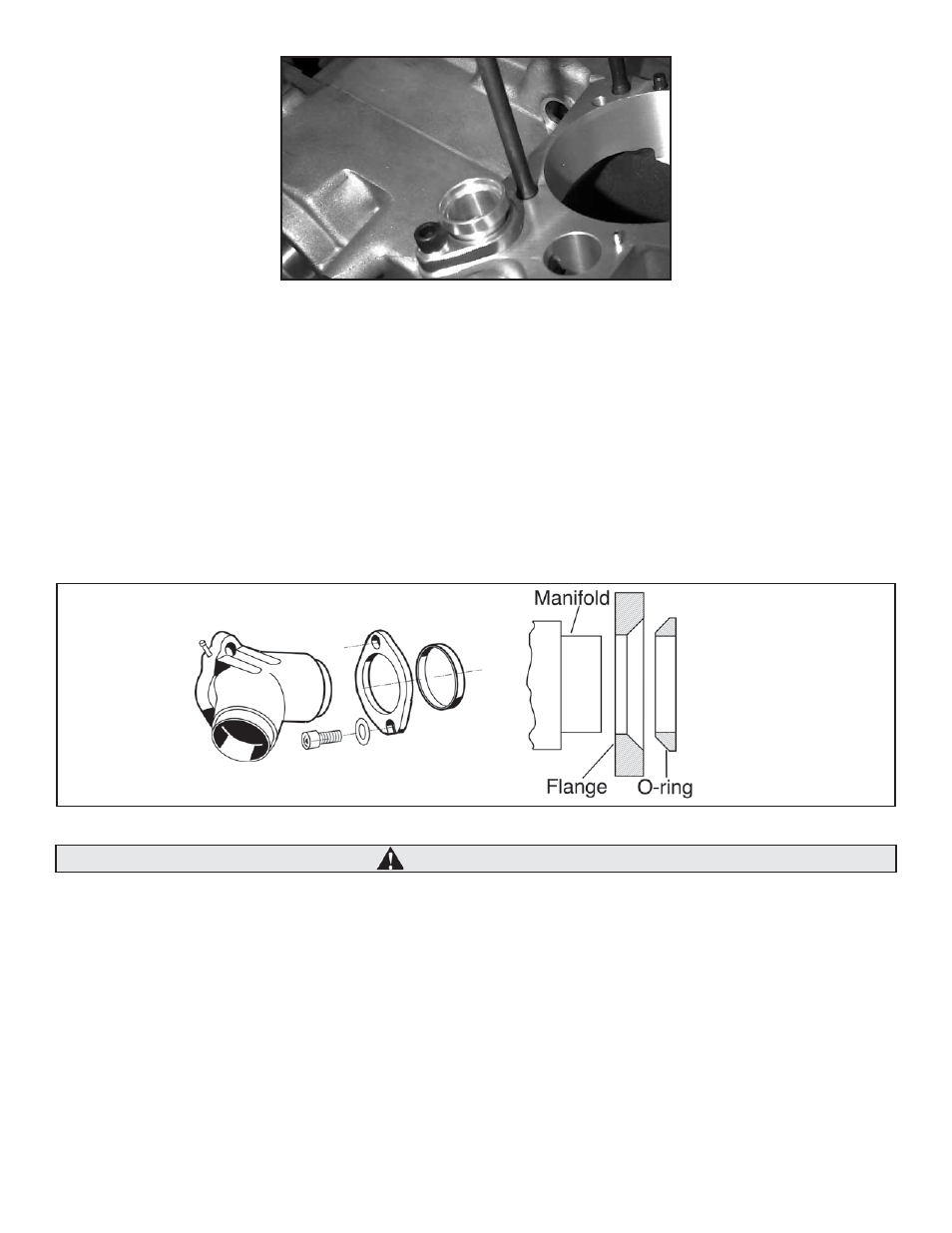

5. Install intake manifold, mounting flanges and o-ring seals. Be sure o-rings and flanges are assembled in correct sequence. Tapered side

of o-ring must fit into tapered side of flange. See Figure 7. Use flange marked “F” on front head and flange marked “R” on rear. Slotted

end of mounting flange goes toward lower manifold mounting hole. Flat washer provided is used on slotted end of flange. Do not

tighten mounting flange screws.

NOTE: I f S&S heads are installed, special S&S manifold must be used because intake port diameters of S&S heads are larger than stock. Special S&S

manifold requires o-ring seals which also have larger than stock diameter to fit O.D. of manifold runners. These o-rings, S&S part 16-0235, are

included and cannot be used in stock applications.

Incorrect o-ring seal may cause air leaks around manifold resulting in lean condition and possible damage to engine.

H. Bolt carburetor and air cleaner assembly in place using carburetor instructions supplied from manufacturer. Final tighten manifold

mounting flanges.

NOTE: Some builders may prefer to install carburetor after engine is installed in frame to reduce the possibility of damage to carb.

I. Install engine in frame according to Harley-Davidson® factory procedures.

NOTE: The stock head mounts, when used with longer than stock cylinder lengths will be short. Use the special S&S head mounts provided.

J. Reassemble gas tanks and all other parts that were dissembled during preparation for top end service. Be sure there are no gasoline leaks

and that throttle opens and closes smoothly and snaps shut when released.

NOTES:

• Throttle must not bind and must snap shut to fully closed position when released.

• Fuel needle and seat assembly must completely shut off fuel supply entering bowl. Fuel line connections must not leak.

Picture 16

Figure 7

CAUTION