S&S Cycle Sidewinder 3 5⁄8 Big Bore Cylinders for Harley-Davidson Sportster Models—1986–2003 User Manual

Page 12

12

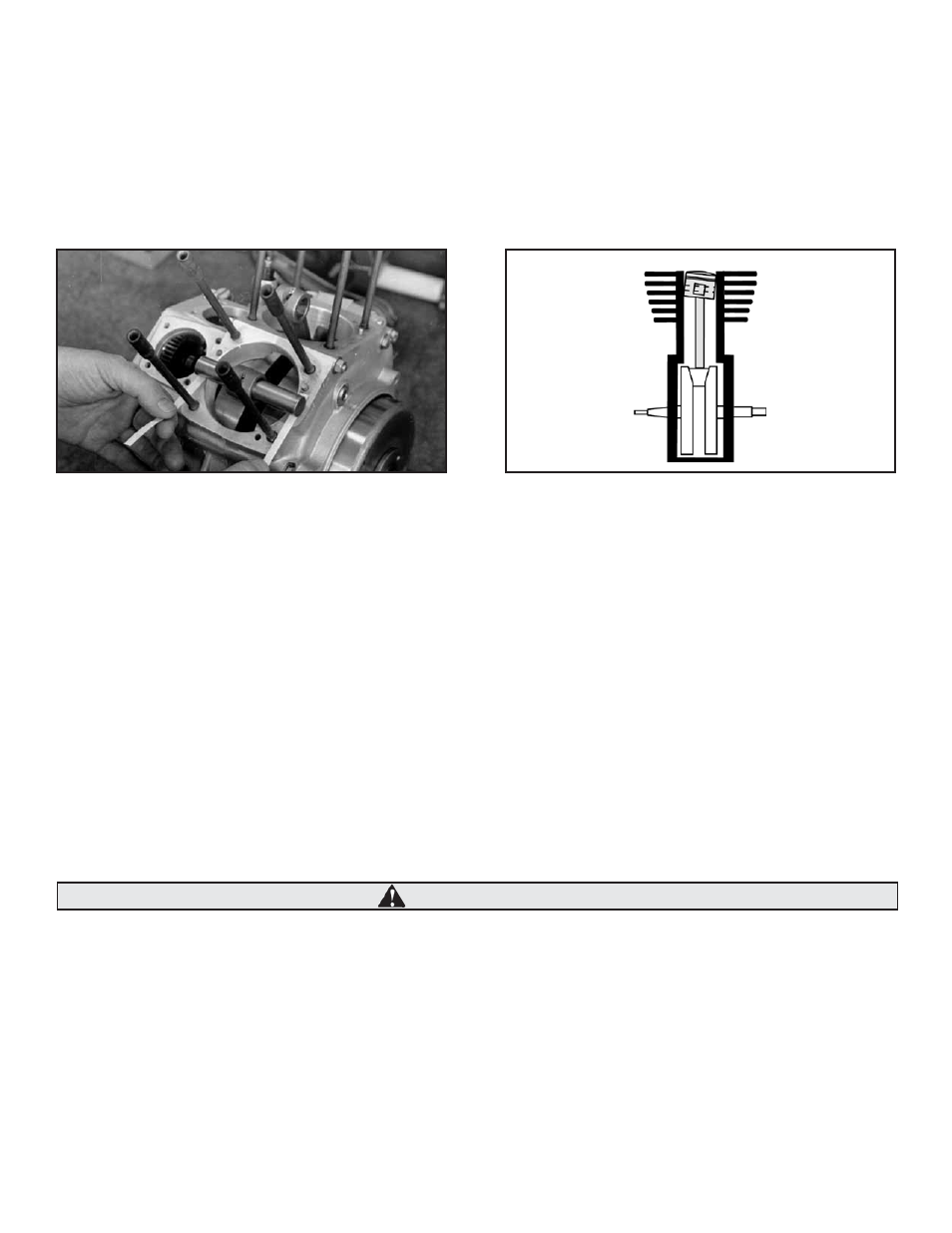

B. Checking Pin Procedure

1. Insert checking pin into wristpin hole. Place strips of paper between checking pin and crankcase cylinder gasket surface and apply

slight downward pressure to wristpin end of rod by rotating flywheels. Pull papers out slowly. Drag on papers should be equal. See

Picture 15, below left.

2. Rotate flywheels in opposite direction until checking pin contacts cylinder gasket surface again. Repeat procedure to rod again. If

drag on papers is equal no bending is required. If one paper is loose, use rod bending tool to tweak rod in direction of loose paper and

recheck.

3. Repeat checking and bending procedure for the other rod.

C. Visual Procedure

1. Install pistons on rods without rings or wristpin clips. Bolt cylinders with gaskets in place.

2. Move piston tight towards camside of engine.

3. Turn engine over in normal direction of travel 2 or 3 revolutions and observe piston during process.

4. Move piston towards driveside of engine and repeat Step C. If inaccuracies are present due to machining variations in cases, cylinders or

pistons, top land of piston deck will appear closer to cylinder wall at one point around circumference. This means that piston is cocked

in cylinder bore and can be corrected by bending rod in opposite direction. Figure 4 , above right, shows an exaggerated side view

of this condition.

5. Repeat Steps B to D for other cylinder.

11. Cylinder Head Preparation

A. Head Gasket Surface Flatness Check - Before top end is assembled, head gasket to cylinder mating surfaces should be checked as follows

1. Thoroughly clean cylinder head gasket surfaces.

2. Place straight edge ruler across head gasket surface at different places around diameter to determine flatness.

3. If unevenness is revealed, machine head gasket surface just enough to make complete contact.

Incomplete contact between gasket surfaces of cylinders and cylinder heads may cause combustion leakage possibly resulting in

damage to cylinders and/or other engine components.

B. Modify 883 Cylinder Head Combustion Chamber - If 883cc cylinder heads are to be used, the combustion chambers must be modified to

improve air flow and reduce the compression ratio. Follow enclosed Instruction Sheet #3883 or #3884 depending on style of combustion

chambers in heads to be used. 1200cc heads do not require this modification.

NOTE: Stock 1200cc heads or modified 883 heads will provide a usable compression ratio but the small valves and ports in stock heads will be a limiting

factor for a large displacement performance motor. To achieve the full potential of the engine it is recommended that the size of the valves be

increased and the ports modified to further improve flow. In weighing the expense and difficulty of these modifications, it may be more cost

effective and results intensive to use S&S® or other aftermarket performance heads.

Picture 15

Figure 4

CAUTION