S&S Cycle Sidewinder 3 5⁄8 Big Bore Cylinders for Harley-Davidson Sportster Models—1986–2003 User Manual

Page 3

3

INSTALLATION

1. Clearance Frame

NOTE: Piston stability in cylinder bore is improved by using pistons with the longest possible skirts. In order to provide a performance engine with the best

possible engine life, S&S increases the cylinder length when the stroke is increased, rather than decreasing the length of the piston. Frame fit, stock

rocker cover to frame tubes and/or rocker cover to gas tank clearances in taller than stock engines must be checked and corrected if needed. It is

recommended that frame clearance be measured before stock engine is removed from frame. The 89" Sidewinder kit is the largest engine that will

fit in a stock frame without major frame modifications.

To check and clearance frame, perform following steps:

A. Before stock engine is removed from frame, measure clearance between rocker boxes and frame. Tightest spot is normally above and

behind rear head.

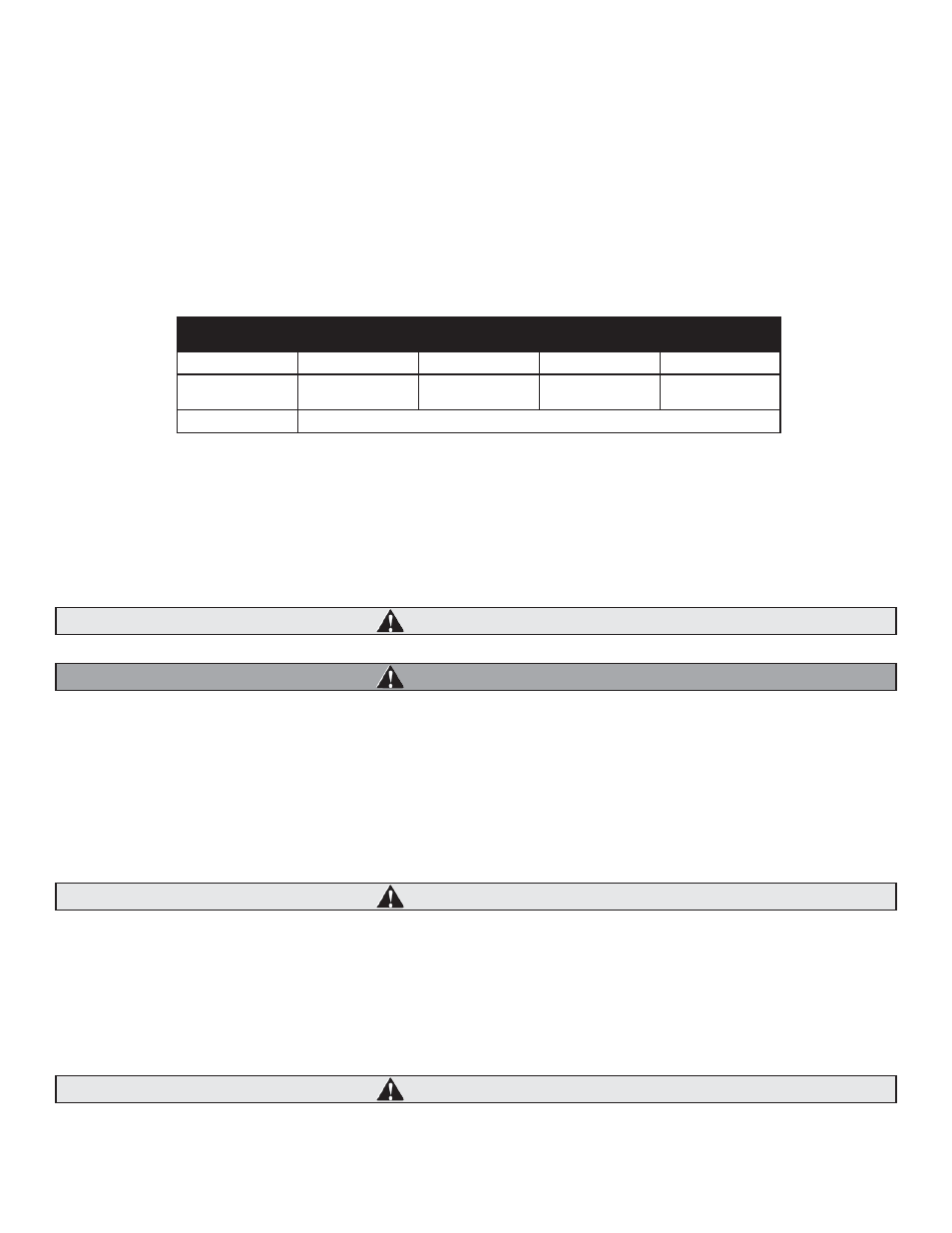

B. Refer to chart 1, above, to determine increase over stock engine height for the kit to be installed. S&S® recommends .100" minimum

clearance between engine and frame. If increased cylinder height of Sidewinder® kit will not leave sufficient room, clearancing will be

required. S&S cylinder heads for Harley-Davidson® Sportster® models are .062" taller than stock, so additional clearance will be required if

S&S heads are to be used.

NOTE: S&S recommends there be .100" minimum clearance between engine and frame. Up to .060" or .070" may be ground from rocker box cover in some

areas for clearance. If cover is ground, be careful not to break through since covers are very thin.

Excessive material removed from rocker cover may damage cover causing oil leaks.

Removing material from welds or frame tube may cause structural damage and possible failure resulting in personal injury or death. If

frame must be modified, work should be done by a professional frame shop.

C. After crankcases have been bored in Step 4, mock up engine using Sidewinder cylinders. Place mocked up engine in frame and determine

if additional clearancing will be needed to provide recommended .100” space between engine and frame.

2. Crankcase Alignment

NOTE: Some crankcase base gasket surfaces on which cylinders are positioned do not align properly. This usually occurs when crankcase halves used

are from different crankcase assemblies and were not paired and machined together during manufacture. It is recommended that crankcases be

checked for misalignment even if crankcase halves are correctly matched to prevent potential oil leaks and other mechanical problems.

Mismatched gasket surfaces due to improperly aligned crankcase halves may cause oil leaks.

A. Clean cases thoroughly and assemble both halves without flywheels. Tighten all case bolts as in final assembly.

B. Place straight edge ruler across base gasket surface. See Picture 1, next page.

C. If crankcase halves are correctly aligned, proceed to Step 3. If any misalignment exists got to Step D in this section.

D. Remove cylinder studs and place masking tape over cam and mainshaft bearings to keep chips out. Consult Harley-Davidson® service

manual for proper cylinder stud removal and installation procedures.

Be careful when removing studs so as not to damage threads in cases. If heat is applied to case around stud to help loosen threads, do

not allow crankcase temperature to exceed 375° F as this may destroy heat treatment of crankcase material.

CAUTION

CAUTION

CAUTION

WARNING

Kit Part

Number

Displacement

Stroke

Cylinder Length

Cylinder Length

Compared to Stock

91-3002

79"

313⁄16"

4.650"

Stock Length

91-3121

91-3123

89"

415⁄16"

5.087"

+.437"

106-5834

CTO

Chart 1