Wear, Readjusting the lock pre-tensioning, Wearing parts – Retsch RM 200 User Manual

Page 31: Checks, Copyright, Alterations

11/6/2012

31

Retsch GmbH 0002

Wear

The scraper and milling tools can wear, depending on

the frequency of milling operations and the material to

be milled. The scraper should be regularly checked for

wear and replaced if necessary. The scraper must be

reset before the metal components come into contact

with the mortar.

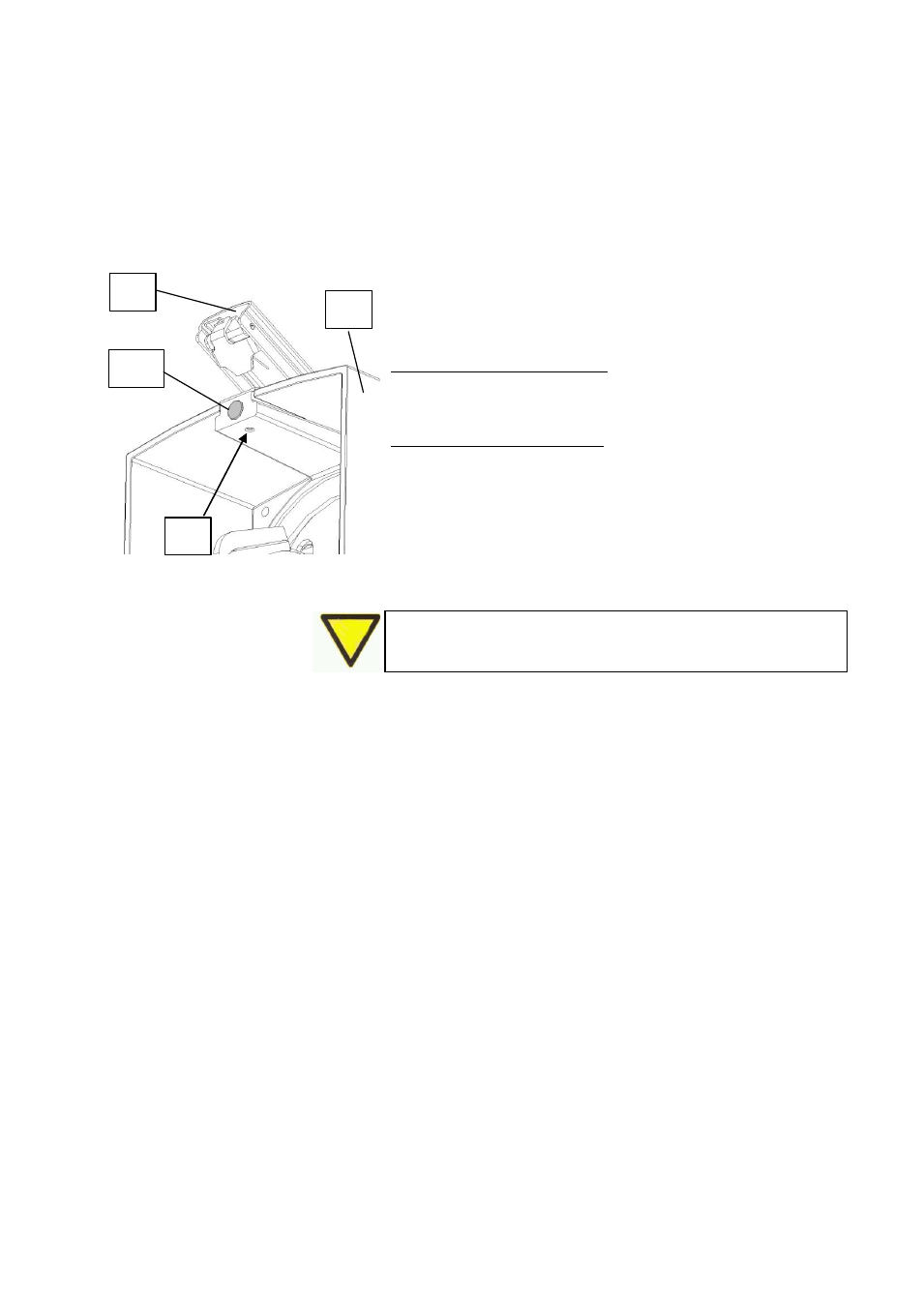

Readjusting the lock pre-tensioning

The lock tension in the lock handle Vg can be

influenced by adjusting the rubber buffer GP.

Open the hood H and loosen the setscrew Gs.

Increasing the lock tension:

Turn the rubber buffer GP in an anti-clockwise

direction

Reducing the lock tension:

Turn the rubber buffer GP in a clockwise direction

Wearing parts

These operating instructions do not include repair instructions.

For your own safety repairs should be carried out only by

Retsch GmbH or an authorised agency and service technicians.

Checks

The function of the hood switch must be checked regularly:

• Switch on the machine with switch D

• Start the milling operation with start button Q

• Open the closing grip F and lift up the hood

• If there is an opening gap of only a few cm the machine is

switched off and F4 appears in the display.

• Delete F4 with stop button R

If switching off does not take place the RM200 must be

checked immediately by Retsch service.

Copyright

Distribution or duplication of this documentation, using

and passing on the contents is allowed only with the

express permission of Retsch GmbH.

Anyone violating is liable to pay damages.

Alterations

Subject to technical alterations without notice.

Vg

Gs

H

GP