Adjusting the pestle, Adjusting the pestle pressure – Retsch RM 200 User Manual

Page 18

11/6/2012

18

Retsch GmbH 0002

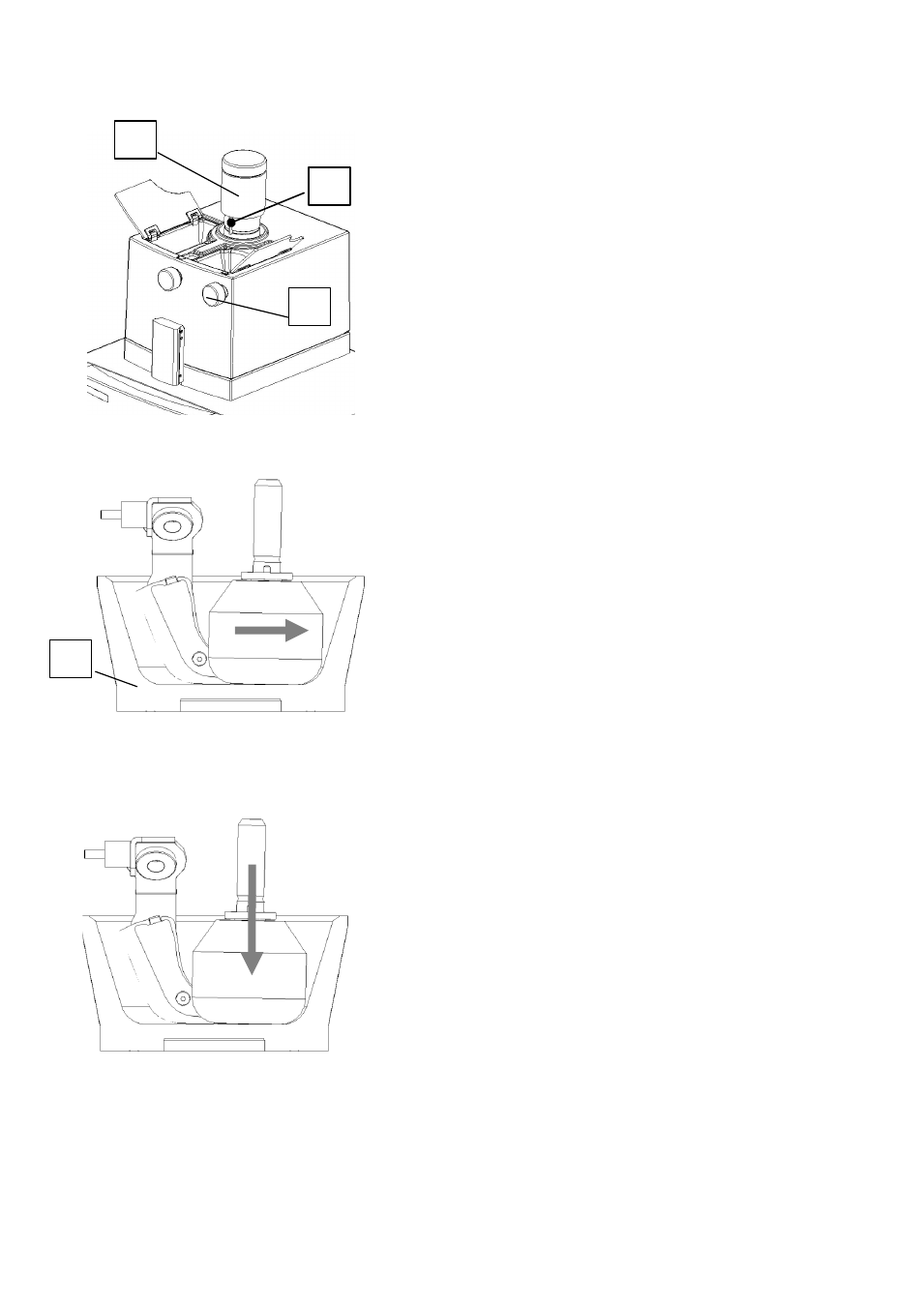

Adjusting the pestle

Fig.5

Fig.6

Fig.7

Fig.5

• The mortar V is installed

• The pestle W is installed and locked in position

• Close the lid M and press the closing grip F shut.

• Turn the rotary grip G anticlockwise and remove.

• Start the machine by switching on with the on/off

switch D and pressing the start button Q

• Move the pestle forwards. To do this turn the pestle

knob L to the left until this reaches the stop. The

setting range is only a few millimeters for several

rotations of the setting knob.

• Then move the pestle backwards again until

resistance is felt. To do this turn the pestle knob L

to the right. Fig.6

• In Fig.6 the optimum setting has been reached

since the lower rounded surface of the pestle is

now running in the lower rounding of the mortar.

• As soon as the pestle shaft is pressed upwards

during the setting process the pestle moves

upwards on the mortar wall and setting is no

longer optimum. In this case turn the pestle knob

back slightly.

Adjusting the pestle pressure

The correct pestle pressure should be determined by

carrying out tests and depends on the material to be

milled and the required degree of fineness.

Increasing the pressure: Fig.5

• Turn the sleeve G clockwise

• This increases the pressing force downwards Fig.7

• The value can be read off on scale H

Reducing the pressure: Fig.5

• Turn the sleeve G anticlockwise

• The values on scale H are reduced

The values indicated on scale H are only for use as

a guide during setting. They can be used as an aid

in reproducing the conditions. However, no

mathematical conclusion regarding the contact

pressure is possible since this depends on the

material to be milled.

G

L

H

W