Retsch RM 200 User Manual

Page 25

11/6/2012

25

Retsch GmbH 0002

Please not that the properties, and therefore the

dangerousness of your sample, can change during

the milling operation.

Quantities from approx. 10 to 190 ml and a max. charging

grain size of 8 mm can be milled and homogenised with the

RM200, without any manual use of force.

The ideal filling quantity depends on the sample quantity and

the properties of the materials to be milled.

Selection of the milling tools depends on the sample material

and the subsequent analysis.

Different milling tools have different characteristics, e.g. the

materials contained in them, hardness or abrasion resistance.

For reliable analytical results you should select the milling

tools in such a way that the milling process is neutral with

regard to contamination.

Please ask for advice in case of doubt.

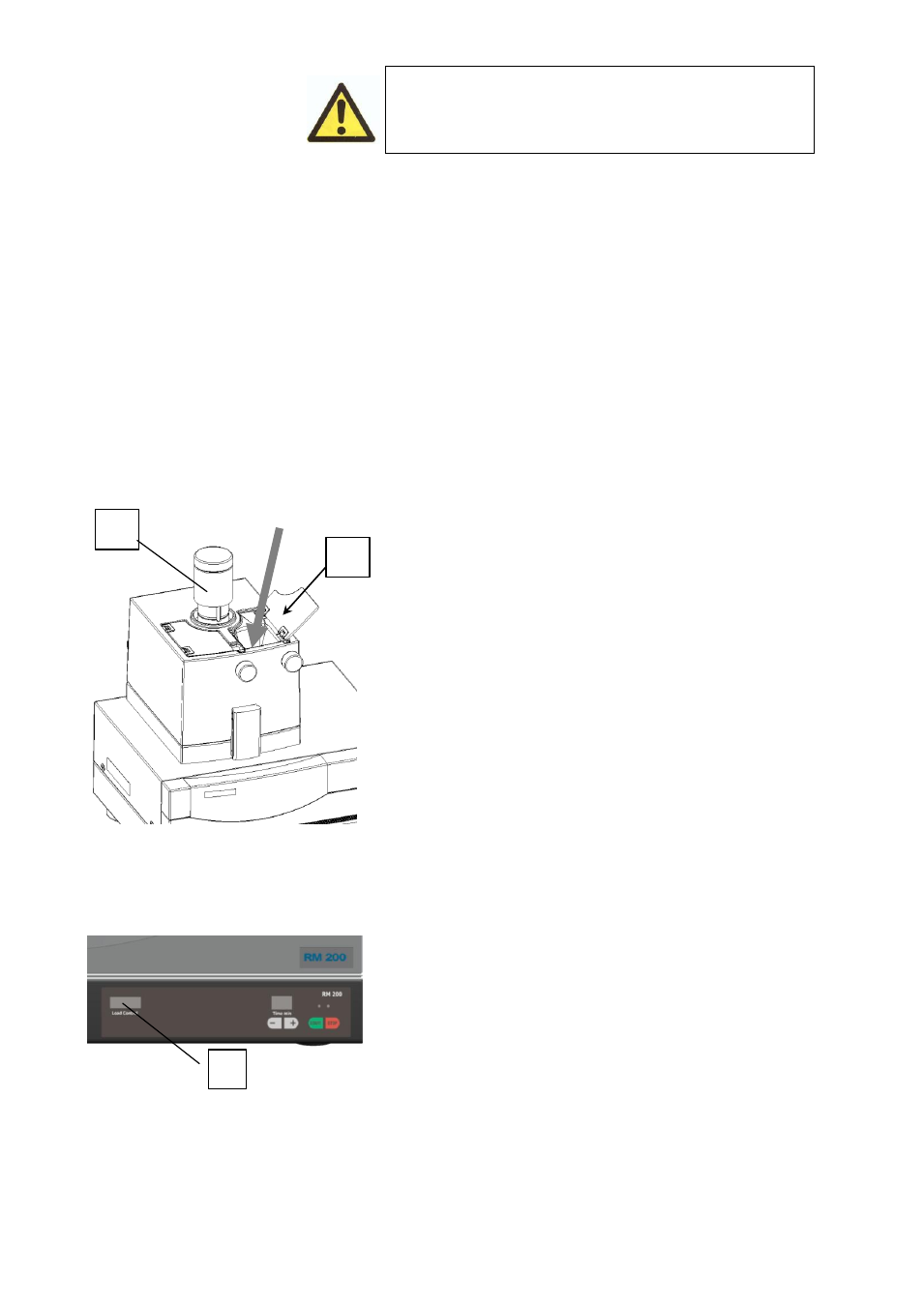

Crushing, mixing and milling of samples with grain

size < 3mm

Fig.16

Fig.17

Connect the RM200 to the power supply, switch on

and start.

The sample is slowly added to the rotating mortar

through the filling opening I . For this purpose the

right-hand Plexiglass cover I is opened. Fig.16

The pestle, which is offset in relation to the centre of

the mortar, presses on the bottom of the mortar and

the material to be milled through spring tension and

its own weight.

Through the resulting friction the pestle is also

rotated with the mortar and this crushes the material

to be milled through pressure and friction. The

pressure can be varied by means of the rotary grip G

Fig.16

The scraper ensures that the sample material is

scraped off the inside wall of the mortar, recirculated

and refed to the milling gap between the pestle and

mortar.

This forced feeding of the material ensures that the

complete sample quantity is well mixed and that

every particle is continuously fed to the milling and

pulverizing process.

Load Control and safety switch off

The load indicator “Load Control” N Fig.17 and 18

serves as a guide for the user. It indicates loading of

the drive motor in 6 stages. At low to full load 1 to 4

green LEDs light up. At slight overloading a yellow

LED lights up in addition.

G

N

I