Laser engraving, Issues to consider – Pololu Custom Laser User Manual

Page 14

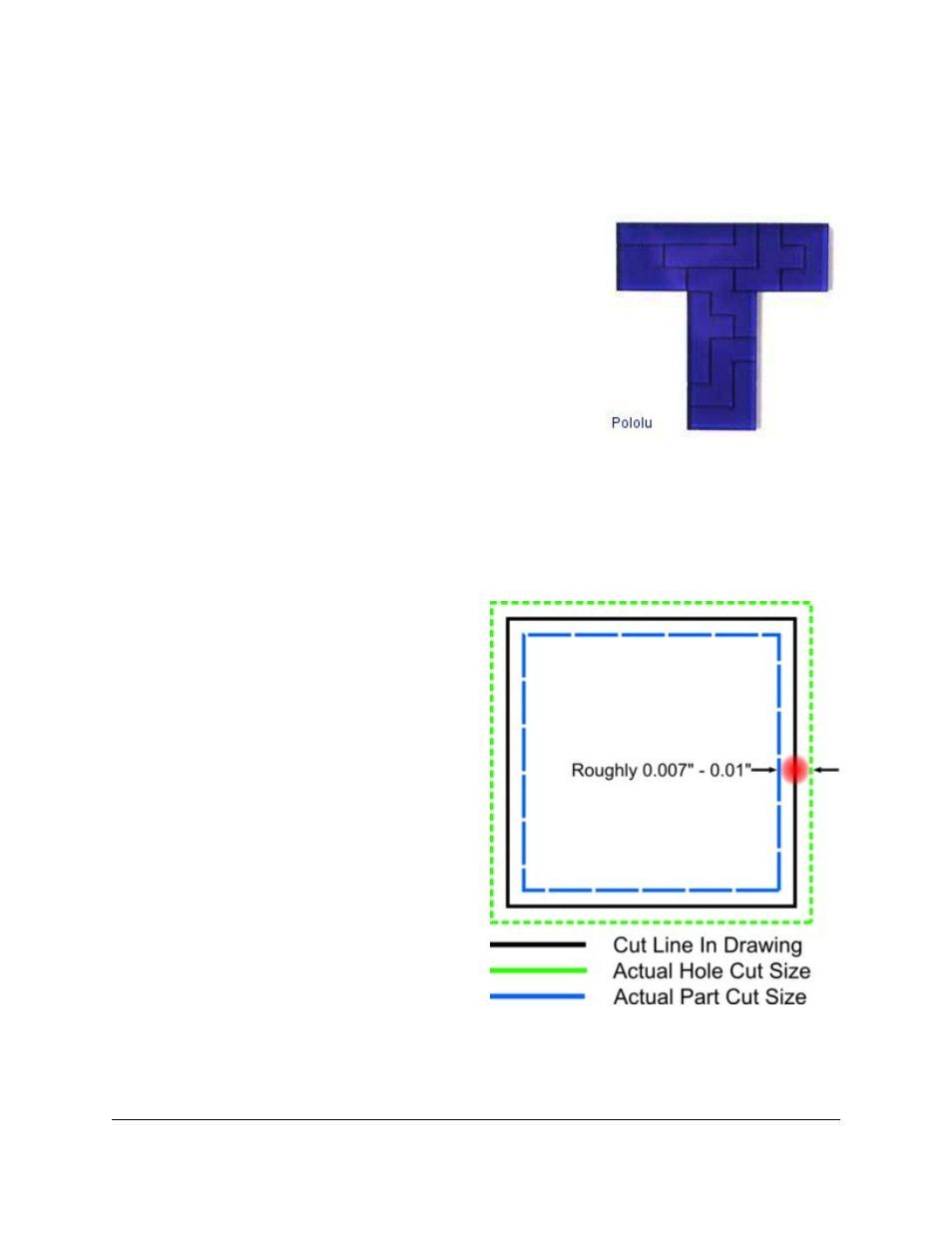

A pentomino piece, showing

engraved solution.

The kerf of our laser beams varies from roughly

0.007" to 0.01" which causes hole and part sizes

to vary.

You might try Weld-On acrylic adhesives for gluing acrylic/Plexiglas parts. Hardware stores usually carry thick, black

glue for gluing ABS parts. You must take care when drilling holes in acrylic, which is brittle and tends to crack (it is

better to have us laser-cut small screw holes). ABS, PETG, styrene, and wood are easier to machine by hand.

Laser engraving

We can do two types of laser engraving (also called laser etching): vector

engraving and raster engraving. Engraving depths can range from barely

scratching the surface to almost going through the material; we cannot control

the depths very precisely, but we will try our best to achieve what you need.

In general, laser engraving is suitable for marking material (not for making

deep grooves for mechanical purposes).

• Vector engraving is for etching lines that are the width of the laser beam

(around 0.01"); it is just like laser cutting, but the laser does not cut all the

way through the material. Vector engraving is limited to line art. The

example uses

vector engraving to show the puzzle solutions on the pieces.

• Raster engraving is slower and more costly than vector engraving, and is

used for engraving bitmaps (JPG or GIF files of logos, photos, etc.), text,

and filled-in areas of your vector drawing file. Raster engraving is more

flexible; you can engrave thin lines as well as recessed areas. The laser blasts away material one pixel at a time,

similar to the printing process used by inkjet printers. We usually raster engrave at 400 dpi, but we can use lower

resolutions and can also use 600 dpi and 1200 dpi settings.

Issues to consider

• The laser cuts at a slight taper (1-2 degrees) since the

laser beam is shaped like a cone (it gets focused from a

larger spot to a small point). The tapering causes one

side of a laser-cut part (the side facing up during laser

cutting) to be slightly smaller than the other side. The

taper is almost unnoticeable in 1/8" material; the thicker

the material, the more noticeable the taper. When using

laser-cut parts such as wheels or gears, you might need

to position the parts in an alternating pattern so that the

tapers “cancel out”.

• The kerf (the thickness of the laser beam) is about

0.010". Please see our file preparation instructions to

learn how to adjust for the kerf.

• Small circles (usually for screw holes) will not be

perfectly circular. Also, the holes will be conical due to

the slight taper of the laser cut as described above. If

you need the holes to be more circular and cylindrical,

we suggest that you have us laser-cut small starter holes,

which you clean up with a drill.

• Plastic thickness can vary by + or – 10%, so you

cannot count on the thickness to be exact when

designing your parts. If you are designing interlocking

parts with slots and tabs and you are trying to create a

tight fit, keep in mind that you can only control the

dimension being cut by the machine (not the material thickness). You will have to decide whether to design the

Custom Laser Cutting Guide

© 2001–2014 Pololu Corporation

4. Capabilities and Limitations of Custom Laser Cutting

Page 14 of 29