We can, Materials, Two-dimensional parts – Pololu Custom Laser User Manual

Page 13

4. Capabilities and Limitations of Custom Laser Cutting

With our custom laser cutting service, you can create custom, two-dimensional plastic parts suitable for a variety of

projects. We can laser cut almost anything you can draw, including sharp angles, smooth curves, small screw holes,

and complex lace designs, and we can also laser engrave text, logos, and photos onto your parts.

We can…

• Cut up to 1/2" acrylic or wood comfortably, and up to 1" acrylic or wood under special circumstances.

• Cut very thin materials including 0.003" mylar sheets

• Cut stainless steel and spring steel up to 0.060"

• Cut, raster engrave, and vector engrave parts up to 47.5" x 47.5"

• Cut holes as small as the laser beam widths, around 0.01"

• Use a variety of file types including DXF, DWG, CDR, AI, PDF, and SVG.

• Draw parts for you based on a sketch

• Cut just one part or thousands of parts, and anything in between (we do provide price breaks)

Materials

We mainly laser cut custom plastic parts, but we can also make custom wood, rubber, and foam parts, as well as thin

custom metal parts. We stock acrylic, ABS, Delrin®, Mylar, PETG, and styrene in various colors and thicknesses. You

may also send us your own material. Please see our

for a complete list of materials we can cut.

We cannot cut glass, polycarbonate (Lexan), carbon fiber, thicker metals, or any material containing chlorine,

including PVC and vinyl. Please see

for a

comprehensive list. If you need a metallic look, we do stock two-tone acrylic-based sheets with a thin, faux-metal top

layer, and you could also consider cutting up to 0.060" stainless or spring steel pieces and adhering them to thicker

backing made of plastic or wood.

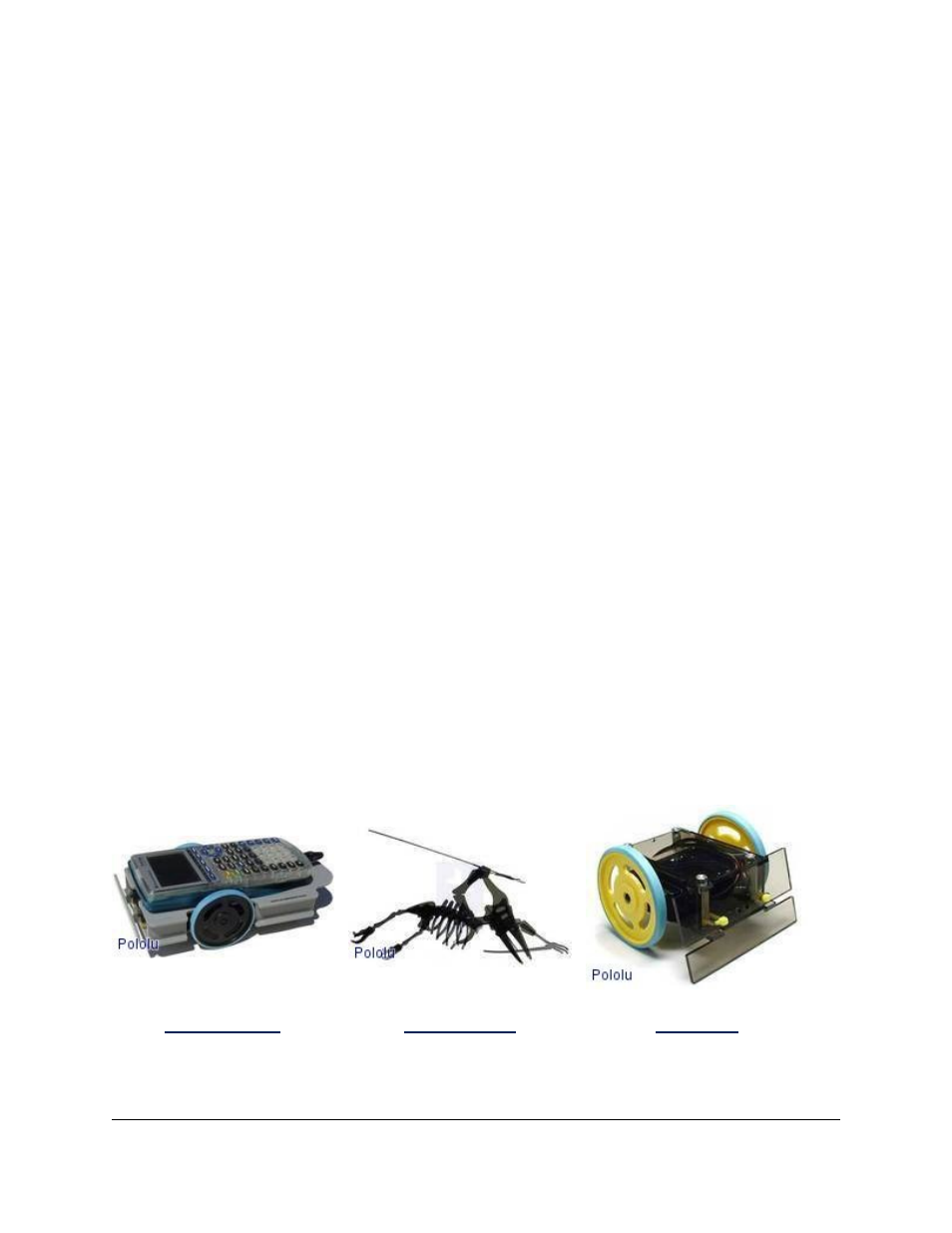

Two-dimensional parts

We can only laser cut two-dimensional parts, but you can create three-dimensional designs from flat pieces with tabs

and slots and some glue, brackets, and screws, as shown in these examples:

Custom Laser Cutting Guide

© 2001–2014 Pololu Corporation

4. Capabilities and Limitations of Custom Laser Cutting

Page 13 of 29