Omnitron Systems Technology iConverter T3/E3 Standalone Module User Manual

Page 2

Only one of the three DIP-switches may

be in the UP position at any one time. The

default setting of the module is T3.

“<225”/”>225” - Coax Distance

When this DIP-switch is in the DOWN

position, a distance of less than 225 ft.

is selected. When in the UP position, a

distance of 225 ft. or higher is selected.

Select the appropriate distance for your

application.

“CEN”/”CDIS” and “FEN”/”FDIS” - Port

Control

When both DIP-switches are in the DOWN position, the ports are enabled. When the

“CEN”/”CDIS” is in the UP position, the coax port is disabled. When the “FEN”/”FDIS”

is in the UP position, the fiber port is disabled.

“PRBS” - Pseudo Random Pattern Generator

When in the UP position, the converter forces Pseudo Random pattern out of the

Coax-Out port. The data received at Fiber-In is discarded and the data at Coax-In is

passed through to Fiber-Out.

Note: Some combinations of DIP-switch settings are illegal, and will be indicated

by the Fiber Test “TST” LED blinking quickly three times followed by a pause.

2) INSTALL STANDALONE MODULE AND CONNECT CABLES

a. The T3/E3 Media Converter is available in wall-mount models. For wall-mounting,

attach the unit to a wall, backboard or other flat surfaces.

To power the unit using the AC/DC adapter, connect the AC/DC adapter to the AC

outlet. Then connect the barrel plug at the end of the wire on the AC/DC adapter

to the 2.5mm DC barrel connector (center-positive) on the chassis. Confirm that

the unit has powered up properly by checking the power status LED located on the

front of the unit.

To power the unit using a DC power source, prepare a power cable using a two-

conductor insulated wire (not supplied) with a 14 AWG gauge minimum. Cut the

power cable to the length required. Strip approximately 3/8 of an inch of insulation

from the power cable wires. Connect the power cables to the standalone unit by

fastening the stripped ends to the DC power connector.

Connect the power wires to the DC power source. The Power LED should indicate

the presence of power.

WARNING: Note the wire colors used in making the positive and negative

connections. Use the same color assignment for the connection at the DC

power source.

NOTE: If mounting with a safety ground attachment, use the safety ground

screw at the rear of the unit.

b. When using the SFP model (8759-0), insert the SFP Fiber transceiver into the Port

1 SFP receptacle on the T3/E3 converter (see the SFP Data Sheet 091-17000-001

for supported transceivers).

NOTE: The release latch of the SFP Fiber transceiver must be in the closed

(up) position before insertion.

c. Connect the BNC cables to the T3/E3 converter and attach the other end of the

cables to appropriate network equipment. The Transmit must attach to the Receive and

forwarded to the BNC-Out and the Fiber-Out. If no data is received at BNC-In, an AIS

pattern is transmitted out both BNC-Out and Fiber-Out. By returning the DIP-switch to

the DOWN position, the unit resumes normal operation.

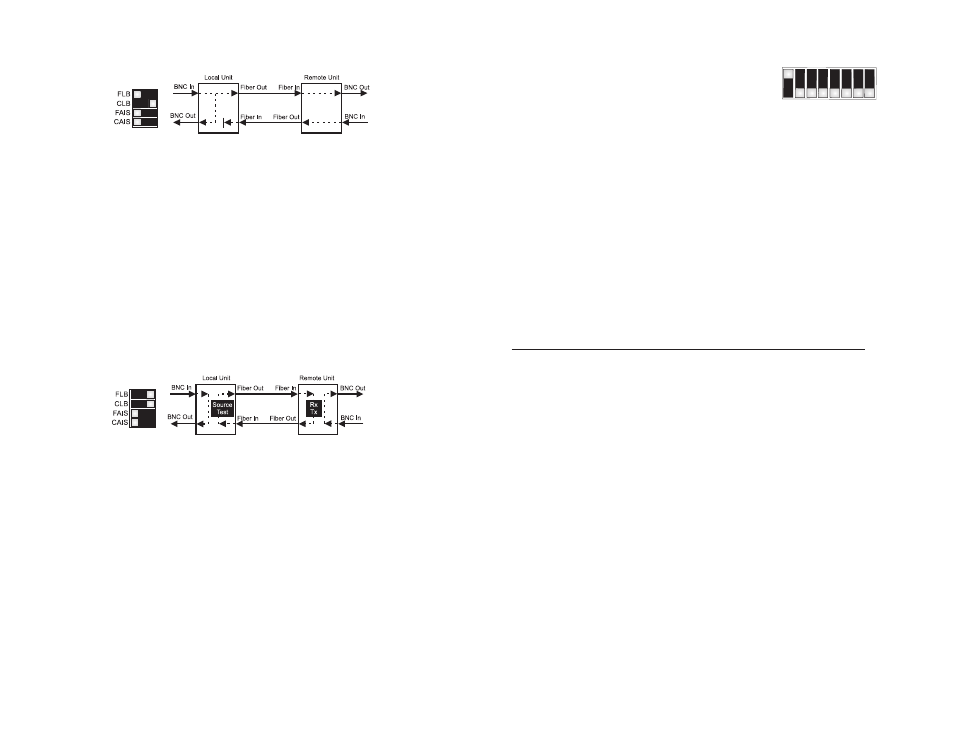

Figure C: Coax Loopback and DIP-Switch Settings

“FLB” + “CLB” - Remote Loopback Mode

When both the “FLB” and “CLB” DIP-switches are in the UP position, they force the

remote unit at the other end of the fiber to loop back its fiber and coax ports (Figure D).

This facilitates test of the fiber cables and the remote unit without having to physically

set DIP-switches on the remote unit. While in this mode, the local unit’s BNC is set to

a local loopback, and its “FLB” and “CLB” LEDs are turned on.

While in the remote loopback mode, the local unit sends a test pattern to the remote

unit. This pattern forces the remote unit into the loopback mode and is also returned

back to the local unit. When forced into the remote loopback mode, the remote unit’s

“FLB” and “CLB” LEDs blink slowly (1Hz).

When the test pattern is received successfully at the local unit’s Fiber-In, the “TST” LED

blinks rapidly (10Hz). Any other data causes slow blinking (1Hz) on the “TST” LED. If

no data is returned to Fiber-In, the LED is turned OFF.

Returning both DIP-switches to the DOWN position, causes the local and remote units

to resume normal operation.

Figure D: Remote Loopback and DIP-Switch Settings

“FAIS” - Force 1s to Fiber (AIS)

When the “FAIS” DIP-switch is in the UP position, an “all ones” pattern is forced out

the Fiber-Out port. The Coax-In data is discarded and Fiber-In data is passed through

to BNC-Out. By returning the DIP-switch to the DOWN position, the unit resumes

normal operation.

“CAIS” - Force 1s to Coax (AIS)

When the “CAIS” DIP-switch is in the UP position, an “all ones” pattern is forced out

the BNC-Out port. The Fiber-In data is discarded and BNC-In data is passed through

to Fiber-Out. By returning the DIP-switch to the DOWN position, the unit resumes

normal operation.

ON-BOARD DIP-SWITCHES

“T3”, “E3” and “STS-1” - Select Protocol

When the “T3” DIP-switch is in the UP position, the T3 protocol is selected. When the

“E3” DIP-switch is in the UP position, the E3 protocol is selected. When the “STS-1”

DIP-switch is in the UP position, the STS-1 protocol is selected.

OFF

OFF

<225

OFF

DOWN

UP

CEN

FEN

OFF

-

-

-

E3

STS-1

>225

T3

CDIS

FDIS

PRBS

-

-

-

Figure E: Board Mounted DIP-Switches