Crimping, assembly and disassembly, Crimping, assembly and disasembly – Northern Connectors Hummel M23-Power - Circular Connectors User Manual

Page 24

128

!

Dimensions and specifications may be changed without prior notice

Crimping, Assembly and Disasembly

Crimping, Assembly and Disassembly

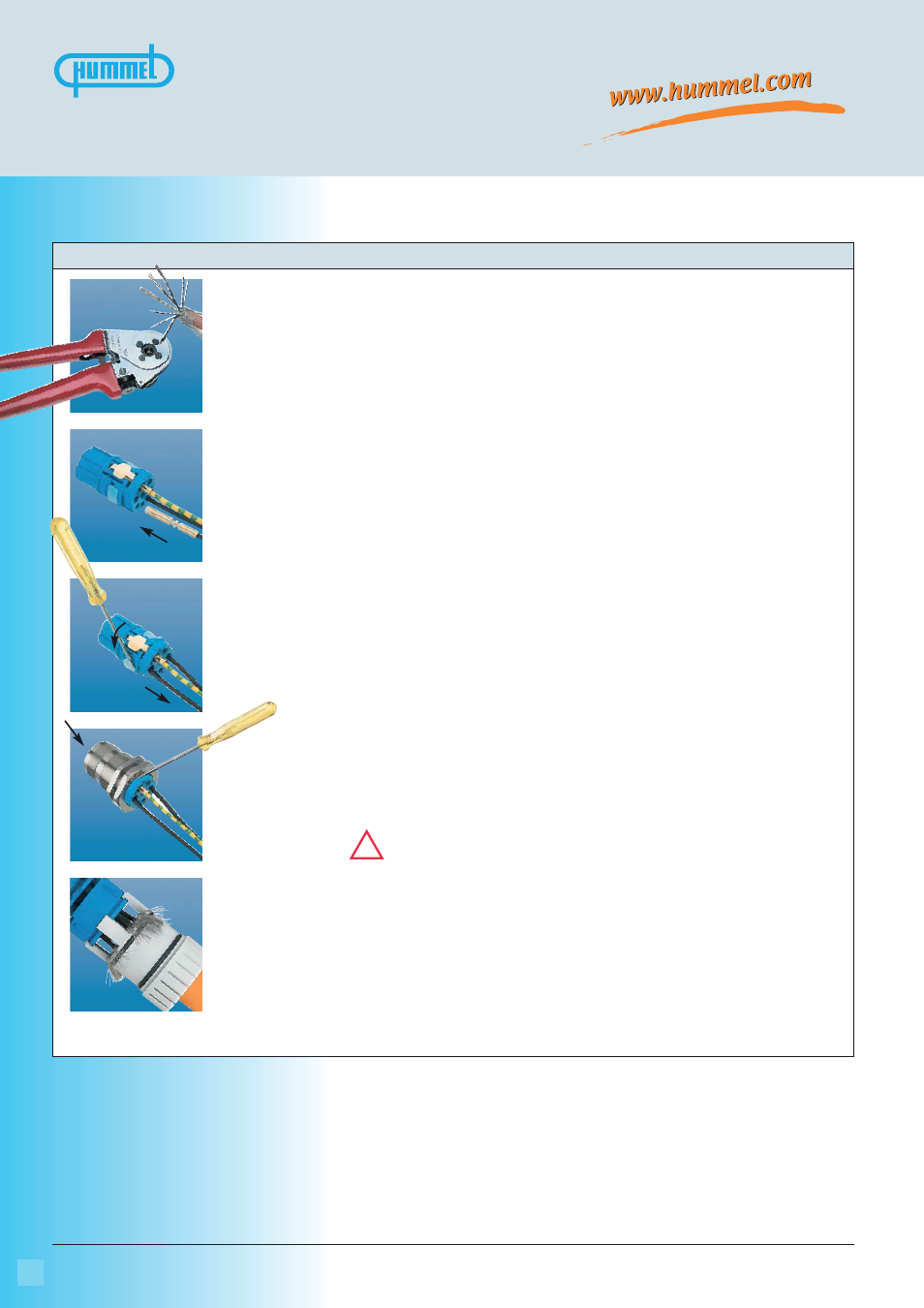

Crimping

- For 1 mm contacts strip wire ends 4 mm (.16“) max.,

for 2 mm contacts strip wire ends 7 mm (.28“) max.

- Dial appropriate setting of crimping tool (page 119/120)

- Push crimp contact into opening of crimping tool

- Insert stripped wire into the funnel shaped end of the crimp contact

- Squeeze handles of crimping tool together, connecting contact to wire

Assembly

- Remove crimped assembly and pull on wire to test connection

- Push into desired position of insert

Note: For 8-pole inserts (4 + 3 + PE) it is recommended to assemble the

large contacts first.

Disassembly of Contacts from Insert

A small screw driver is required.

- Using the screw driver, push the white clip ring out of the insert

- Pull the contacts out of the insert

- Replace the white clip ring

- Reinsert the contacts

Disassembly of Insert from Housing

A small screw driver is required. Push locking tongue, located above the PE-contact,

down. By simultaneously pushing on the front side of the insert, it can be disassembled

from the housing.

Shielding

- Assemble strain relief insert with insert

- Fold stranding of the shield back over the first O-Ring of the strain relief insert

- Cut back the overextending braid

The stranding of the shield is not allowed to touch the second O-Ring.

Otherwise the assembly may not be proof.