Logic interface: ttl input and output – New Era NE-1600 Multi-Phaser Programmable Syringe User Manual

Page 47

New Era Pump Systems Inc.

WWW.SYRINGEPUMP.COM

Model NE-1600/NE-1800 Multi-Phaser™

Publication #1200-02

42

8/1/14

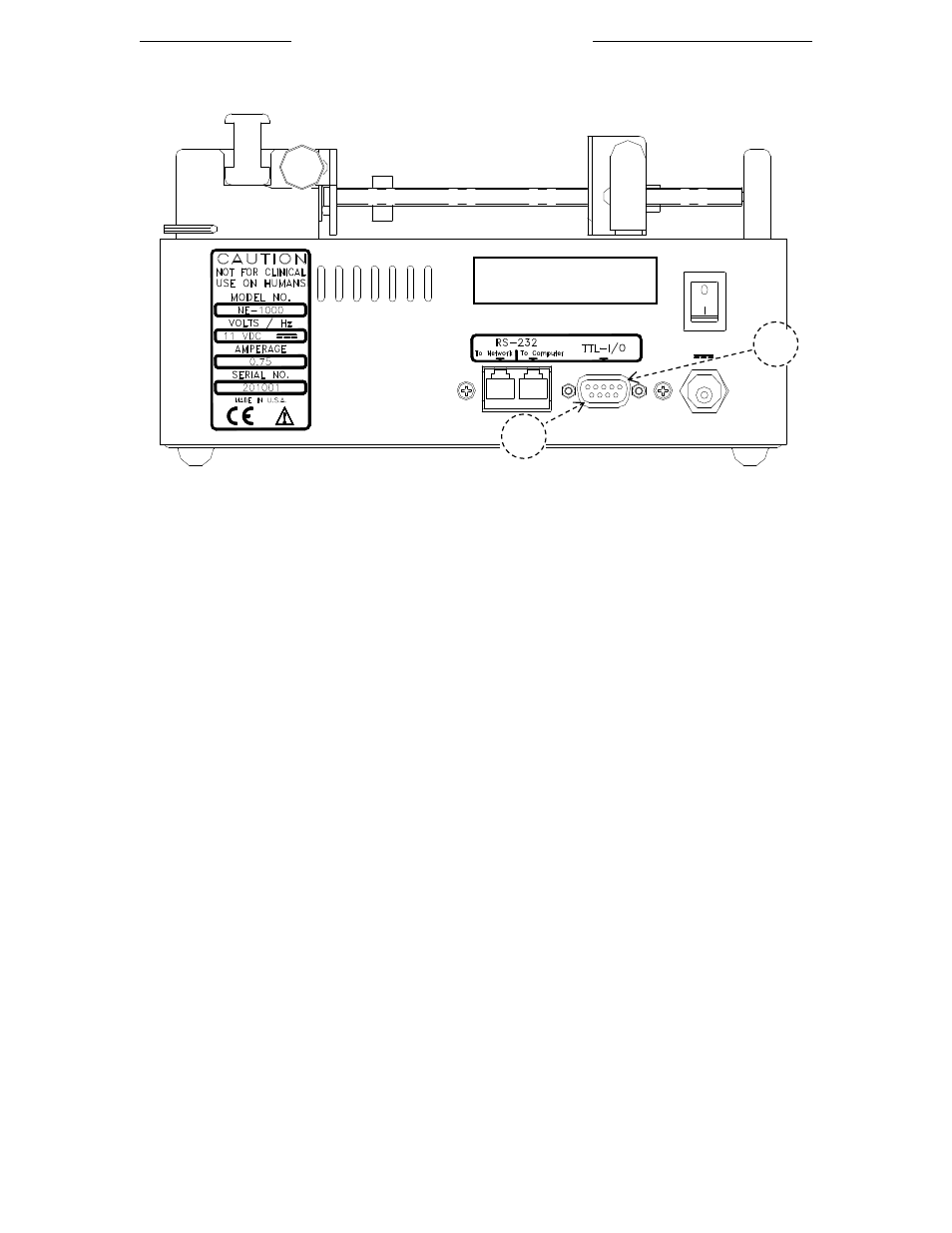

10. Logic Interface: TTL Input and Output

Figure 2: Rear of Pump

On the rear of the pump is a DB-9 connector, below the ‘TTL-I/O’ label, which is used for TTL I/O. The logic

signals on this connector permit bi-directional control with external equipment.

Control input TTL logic levels must be held steady for a minimum of 100 ms to be recognized. To minimize

the possibility of false signals caused by glitches and ringing, which could be caused by the closure of

mechanical switches, TTL control inputs are firmware filtered. With a sampling period of 50 ms, glitches of

less than 100 ms are filtered out.

Edge detection requires the detection of a change in TTL levels. With a minimum of 100 ms to detect a level,

an edge requires a minimum of 200 ms to be detected. Since the next level change can be detected in 100 ms,

creating another edge, the maximum edge to edge frequency is 10 Hz.

Edge changes to the ‘Pumping Direction’ and ‘Operational Trigger’ inputs must occur at least 50 ms apart.

Falling edge refers to a logic high to logic low transition. Rising edge refers to a logic low to a logic high

transition. To guarantee recognition of logic levels, voltages on the input lines must be within the following

ranges:

TTL logic low (0):

0 to 1.5 V

logic high (1):

3.5 to 5.25 V

The Vcc and Ground pins, pins 1 and 9, are for logic reference only. To assure proper voltage levels, the

Ground pin should always be connected to the signal ground of a sensing or controlling device that is attached

to any other pin on the TTL I/O connector. The Vcc pin should not be used to source current. The TTL I/O

pins are defined as follows:

NEW ERA PUMP SYSTEMS ™

WWW.SYRINGEPUMP.COM

(631) 249-1392

Farmingdale, NY [email protected]

Pin

9

Pin

1