Gaff sharpening instructions, Gaff assembly and ordering instructions – Klein Tools Pole and Tree Climbers, Including Gaff Sharpening User Manual

Page 7

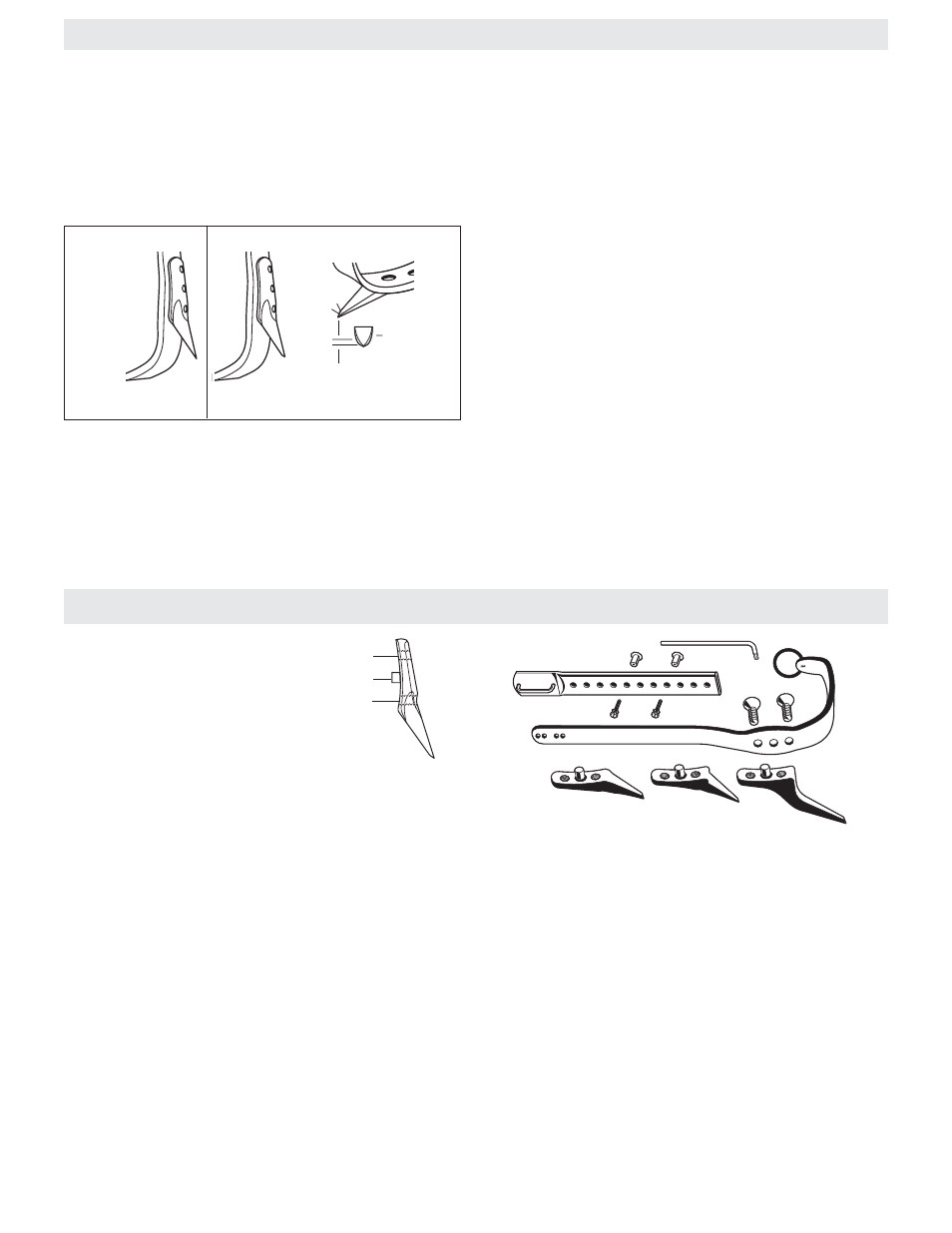

Gaff Sharpening Instructions

(continued)

4.

Do not make a needle point.

In order to not make a needle point (see Figure 21), file

both side slopes to obtain straight edges. The top ridge of

the gaff (see Figure 20) must be perfectly straight from the

tip back at least 1" (25.4 mm) and should not be altered.

Deep nicks, dents, or scratches along the top ridge require

gaff replacement. The final point must always be in the top

ridge of the gaff.

5.

Maintain proper shape on underside of gaff.

The underside of the gaff should be perfectly straight (flat)

to within 1/4" (6.35 mm) of the point, then rounded slightly

toward the top ridge of the gaff on a radius of 1/4" (6.35

mm) (see Figure 19). At a distance of 1/16" (1.59 mm)

back from the point, the width should be a minimum of

3/32" (2.38 mm) measured on the underside of the gaff

(see Figure 22). The remainder of the underside should

be kept perfectly straight (see Figure 20).

6.

Replace gaffs when necessary.

Pole climbers should not be used after the underside of

the gaffs are worn or filed to 1-7/16" (37 mm) long. Tree

climbers should not be used after the underside of gaffs

are worn or filed to 2-1/4" (57 mm) long. When bark

thickness measures more than 2-1/2" (64 mm), make sure

the gaff has adequate length to properly penetrate the

wood under the bark.

When climber gaffs measure less than the above limits,

they should be replaced with a new pair. For your

protection, Klein recommends that climbers be replaced

when original gaff and two replacement gaffs have been

used on the climbers.

7.

Check final result after sharpening.

Use the KG-1 gauge when inspecting the gaff. Replace

the gaff if it fails the gauge tests.

Wrong

Sharp Cutting Edges

Figure 21

Right

Cross Section

View of Point

3/32"

1/16"

7

Figure 22

Gaff Assembly and Ordering Instructions

Gaff Assembly

1.

Attach gaff with locator pin (B) to

middle hole of leg iron.

2.

Thread longer screw (C) into

bottom hole (nearest gaff point). Do

not seat screw.

3.

Thread shorter screw (A) through flat portion of gaff.

4.

Alternate tightening of both screws until seated. Do not

exceed 24 ft.-lb. torque on screw.

Gaff Ordering. Gaffs are supplied in pairs with TORX®

screws and wrench. No. 72 gaffs, No. 86 gaffs, and No. 07

gaffs are interchangeable and fit all Klein replaceable-gaff

climbers.

Cat. No.

Description

72

Pair of 1-1/2" (38 mm) gaffs. For pole

climbers only.

86

Pair of 1-9/16" (40 mm) gaffs. For pole

climbers only.

07

Pair of 2-3/4" (70 mm) gaffs. For tree

climbers only.

A

B

C

86

07

72