Procedures for inspecting climbers and gaffs – Klein Tools Pole and Tree Climbers, Including Gaff Sharpening User Manual

Page 5

5

Procedures for Inspecting Climbers and Gaffs

(continued)

4.

Check gaff thickness with Klein Gaff Gauge.

For pole gaffs only, insert the gaff as far as

possible through the large opening in the gauge marked

“TH” (Figure 9). Make sure the top ridge is flush against

the gauge base. The point of the gaff should fall within the

limits formed by the last line and the edge of the gauge as

shown. If it does, the gaff is the proper thickness, as

measured approximately 1" (25.4 mm) from the point.

For pole and tree gaffs, insert the gaff as far as

possible through the small opening in the gauge marked

“TH” (Figure 10). Make sure the top ridge is flush against

the gauge base. The point should fall within the center two

lines, as shown. If it does, the gaff is the proper thickness,

as measured approximately 1/2" (12.7 mm) from the point.

5.

Check gaff width with Klein Gaff Gauge.

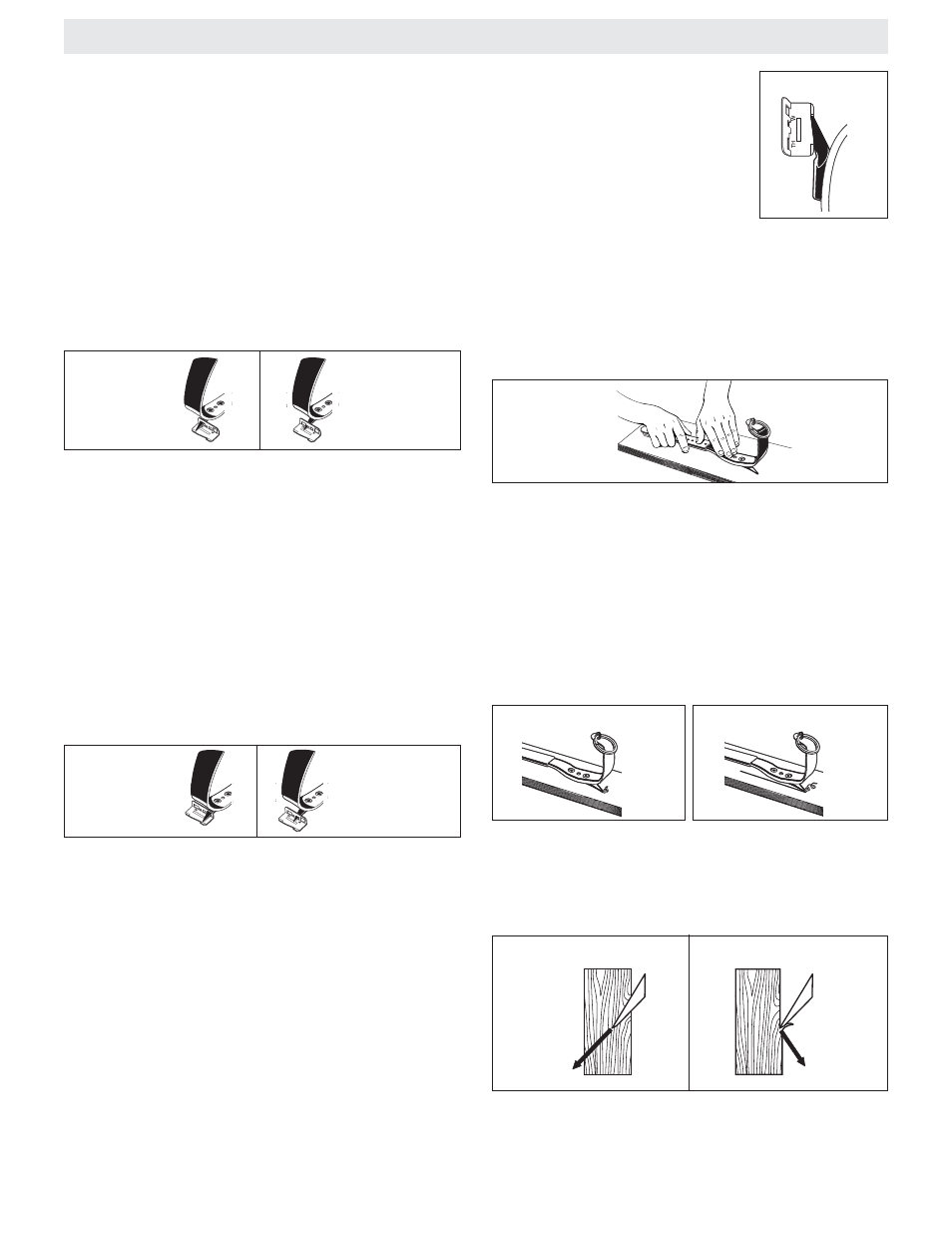

For pole gaffs only, insert gaff as far as possible through

the large square opening in the gauge marked “W” (Figure

11). Make sure the top ridge is flush against the gauge

base. The point should fall within the limits formed by the

last line and the edge of the gauge as shown. If it does,

the gaff is the proper width, as measured approximately 1"

(25.4 mm) from the point.

For pole and tree gaffs, insert gaff as far as possible

through small opening in the gauge marked “W” (Figure

12). Make sure the top ridge is flush against the gauge

base. The point should fall within the center two lines as

shown. If it does, the gaff is the proper width, as measured

approximately 1/2" (12.7 mm) from the point.

6.

Check gaff profile/contour with Klein Gaff Gauge.

For pole and tree gaffs, place the side of the gaff along

the front edge of the gauge with the gaff point resting in

the notch. The point should follow the configuration of the

gauge to assure the proper “rounding off” of the tip within

1/4" (6.4 mm) of the point (see Figure 13).

Minimum safe length for a pole-climbing gaff is 1-7/16"

(37.5 mm), measured on the underside of gaff. Minimum

safe length for a tree-climbing gaff is the greater of the

following: (a) 2-1/4" (57 mm),

measured on the underside of the

gaff, or (b) long enough to penetrate

the core of the tree.

Before

climbing, always test the

penetration of tree gaffs at the base

of the tree to be sure gaffs extend

through the bark and properly

penetrate the wood.

7.

Check gaff sharpness with the “plane test”.

Step 1: Place climber with gaff pointing downward and

upper strap loop resting against a horizontal board or

pole. Hold the leg iron parallel to the wood surface, with

the stirrup vertical. Push the climber horizontally in the

direction of the gaff without any downward pressure

except the weight of the climber (see Figure 14).

Step 2: The gaff is properly sharpened if it buries itself in

the wood within a few inches of its starting position and

can no longer be moved forward (see Figure 15). The gaff

is not properly sharpened if it merely slips, slides, or

plows a shallow groove in the wood (see Figure 16). In

this case, either replace the gaff following the “Gaff

Assembly and Ordering Instructions” or resharpen the

gaff following the “Gaff Sharpening Instructions”, both

contained in this booklet. A resharpened gaff must be

tested for proper width, thickness, and point profile, and it

must also pass the “plane test” before use.

The “plane test” reveals possible penetration prob-

lems not noticeable to the naked eye. Figure 17 shows

how a properly sharpened gaff cuts its way into the

pole for proper support. Figure 18 shows how an

improperly sharpened gaff can “cut-out”.

Figure 11

Figure 12

Figure 9

Figure 10

Figure 13

Figure 15 - Right

Figure 16 - Wrong

Figure 18 - Wrong

Figure 17 - Right

Figure 14