INFICON Crystal 12 Sensor User Manual

Page 54

4 - 10

07

4-

39

8-

P1A

Crystal12 Sensor Operating Manual

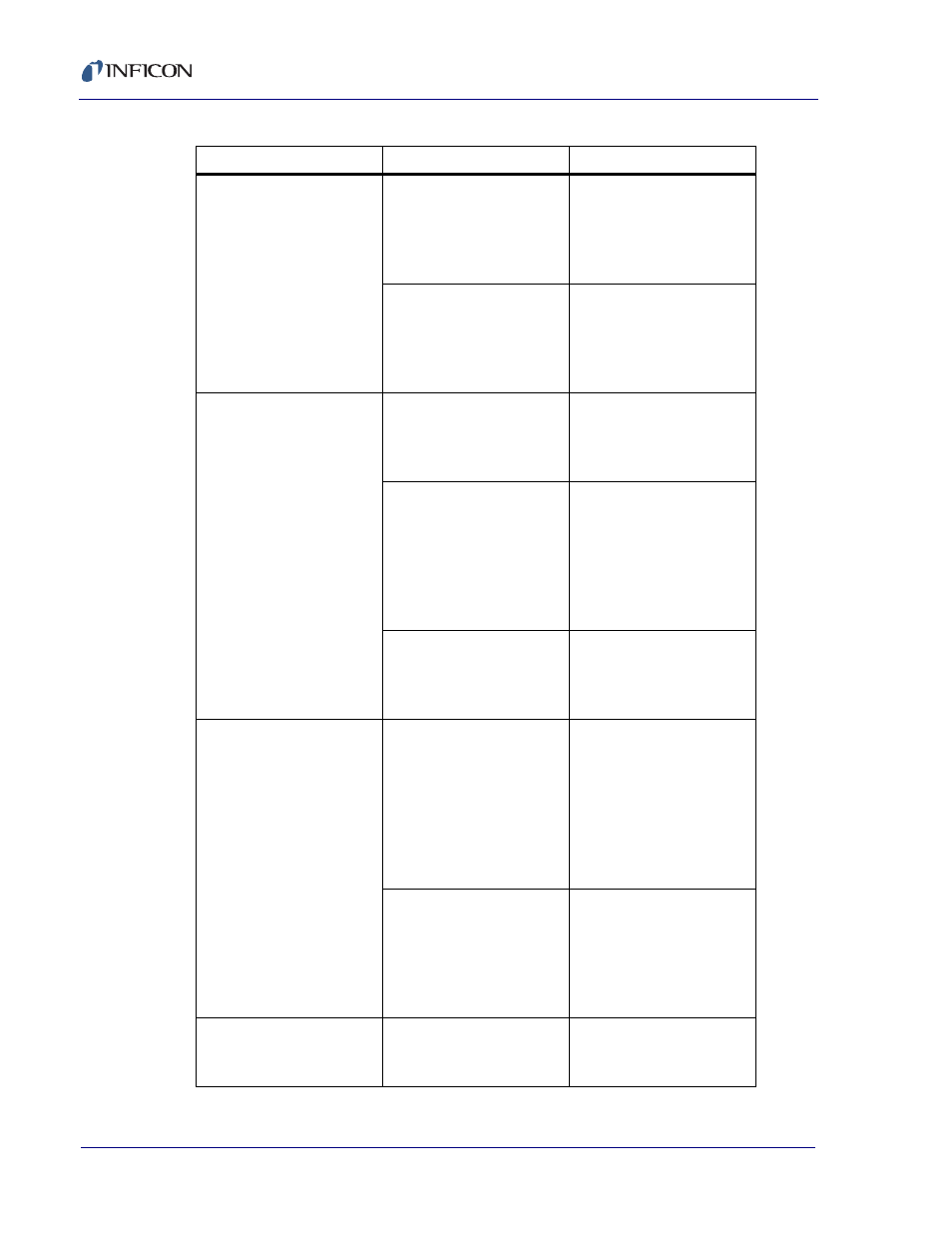

Crystal oscillates in

vacuum but stops

oscillation after open to air.

Crystal was near the end

of its life; opening to air

causes film oxidation,

which increases film

stress.

Replace crystal

Excessive moisture

accumulation on the

crystal.

Turn off cooling water to

sensor before opening it to

air; flow hot water through

the sensor when the

chamber is open.

Thermal instability: large

changes in thickness

reading during source

warm-up (usually causes

thickness reading to

decrease) and after the

termination of deposition

(usually causes thickness

reading to increase)

Crystal not properly

seated.

Check and clean crystal

seating surface of the

crystal carousel. Refer to

.

Excessive heat input to

the crystal.

If heat is due to radiation

from the evaporation

source, move sensor

further away from source

and use sputtering

crystals for better thermal

stability.

No cooling water.

Check cooling water flow

rate. Flow rate should be a

minimum of 150-200

cc/min @ 30 °C max.

Poor thickness

reproducibility

Erratic source emission

characteristics.

Move sensor to a different

location; check the

evaporation source for

proper operating

conditions; insure

relatively constant pool

height and avoid tunneling

into the melt.

Material does not adhere

to the crystal.

Check the cleanliness of

the crystal surface;

evaporate an intermediate

layer of proper material on

the crystal to improve

adhesion.

Carousel Change-Out and

Xtal Fail messages remain

after installing carousel.

Open circuit.

Initiate a Crystal Switch or

Rotate Head function.

Table 4-1 Troubleshooting (continued)

Symptom

Cause

Remedy