2 procedure – INFICON Crystal 12 Sensor User Manual

Page 47

4 - 3

07

4-

39

8-

P1A

Crystal12 Sensor Operating Manual

Alignment tool assembly 750-254-G2 (Included in 750-268 kit)

Regulated air supply 80-90 PSIG (5.5 bar - 6.2 bar) [550 kPa - 620 kPa]

NOTE: 75 PSIG (5.2 bar) [520 kPa] is for alignment purposes only.

4.3.2 Procedure

With the required equipment at hand, proceed as follows:

1

Temporarily connect an air supply to the bellows assembly (item 37,

) supply tube. Regulate the air pressure to 75 PSIG (5.2 bar) [520

kPa].

2

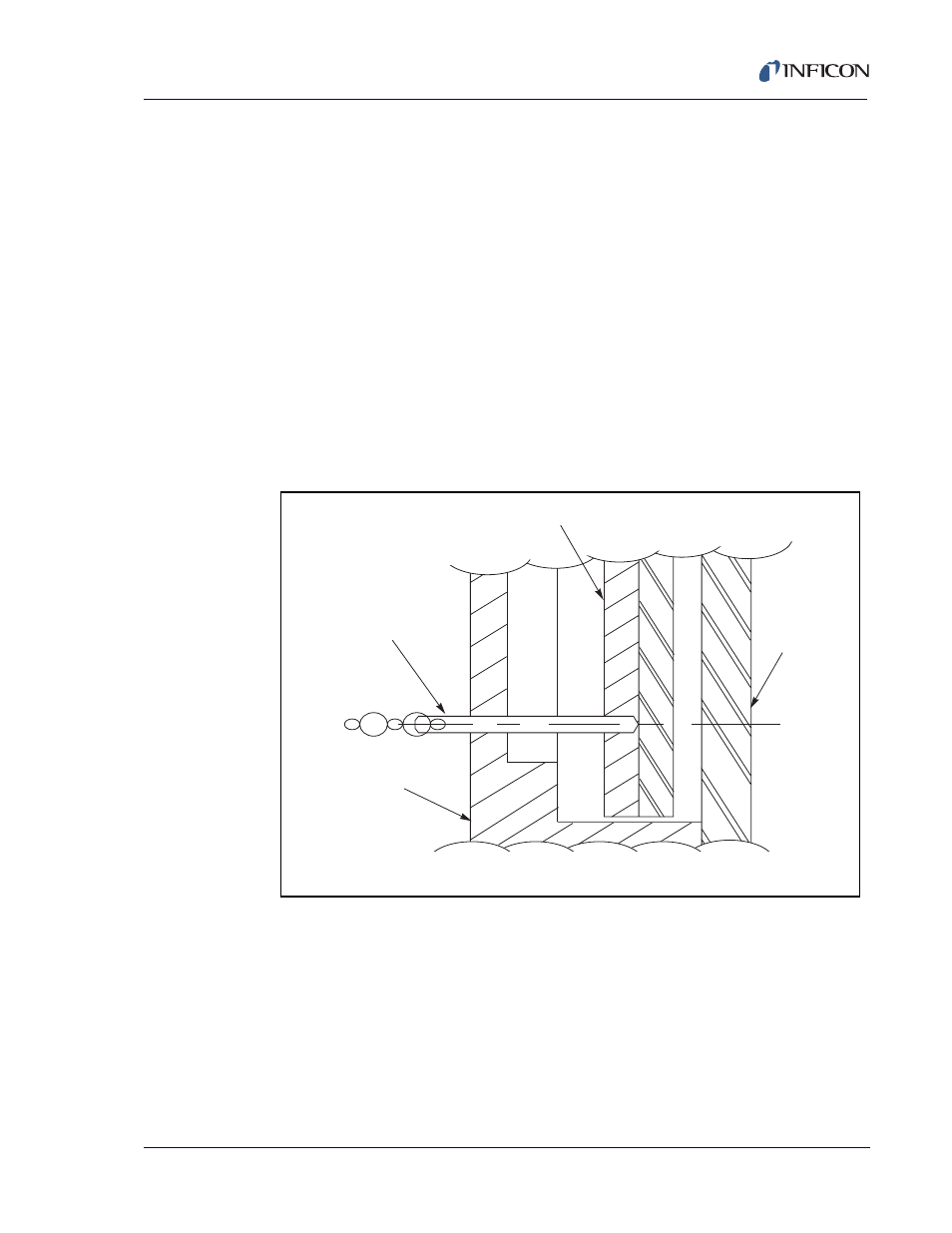

Insert the 0.09375" diameter alignment pin (of the 750-254-G2 assembly) in the

alignment hole (if not already installed) as shown in

. The crystal

carousel may need to be rotated to achieve the alignment condition shown in

Figure 4-1 Alignment Pin Installation

3

Remove the actuator cover (item 22,

) and its related

hardware (items 6 and 7,

4

Loosen the set screws (two set screws per item) of the ratchet (item 29,

) and the stop ratchet (item 31,

5

Loosen the #2 fastener (item 5,

) that attaches the detent

(item 25,

) to the bellows assembly item 37,

). Do NOT remove detent.

Crystal Carousel

0.09375 dia. Alignment Pin

750-254-G2

Carousel

Housing

Weldment

Front

Deposition

Shield