INCRA TS-LS Table Saw Fence User Manual

Page 5

The rail positions described above will provide support for

the base of the TS-LS for work on either the left or right

side of the blade. Left hand range is about 16” and right

hand range is 32” or 52” depending on your rail length.

If you wish to customize the setup to suit your needs, just

slide the rails left or right as necessary. Keep in mind

that sliding the rails to the right subtracts from your range

to the left, and sliding the rails to the left subtracts from

your range to the right.

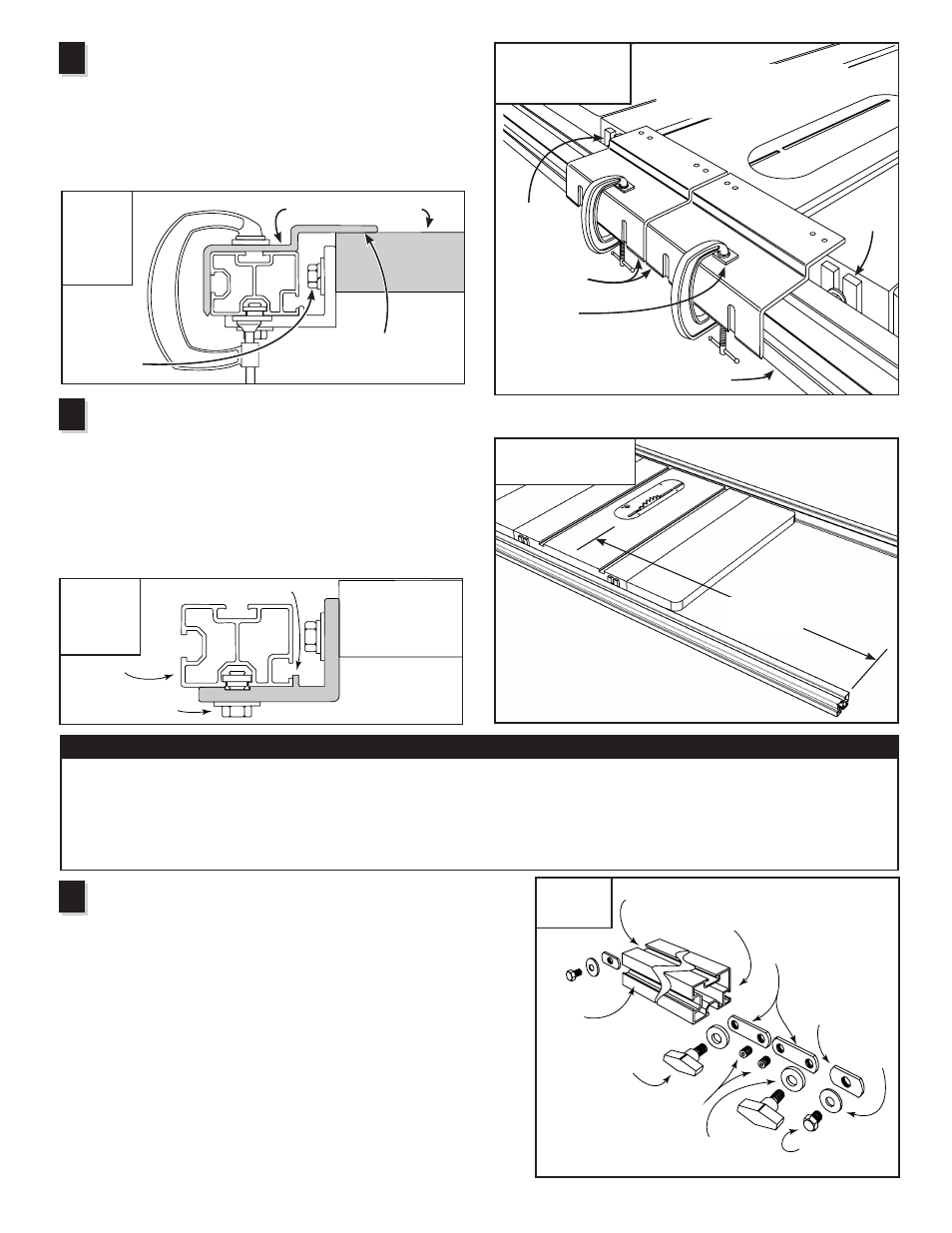

Set final mounting bracket position

Clamp the (2) TS-LS base clamps to the front rail

as shown in Fig. 4 and loosen the bolts that secure the

mounting brackets to your table saw. The rail and mounting

brackets will drop down until the base clamps touch the top

of your saw, Fig. 5. This locates the final mounting bracket

position. Tighten the bolts that secure the mounting brackets

to your table saw. Repeat for the rear rail.

Mounting

bracket

FIG. 4

Set final mounting

bracket position

Base clamps

Clamp pad

Rail

Mounting

bracket

First: Clamp base clamps to rail.

Use clamp pads to avoid marring

anodized surfaces

Second: Loosen both mounting

bracket bolts. Brackets will

lower slightly

Set final rail position

Loosen the bolts that secure the main rails to their

mounting brackets and slide the rails so that they extend 45”

to the right of the saw blade (for 72”-long rails) or extend 65”

to the right of the blade (for 92” rails) as shown in

Fig.6. Push

the rail against the short vertical leg on the mounting bracket

and tighten the bolts that hold the rail in place. See

Fig. 7

below.

NOTE: If you have also purchased a router table

extension wing, complete all assembly instructions in this

manual BEFORE attaching the router table.

4

5

FIG. 5

Tighten

mounting

bracket

bolts

Base clamp

Table saw top

Mounting

bracket bolt

Mounting bracket is at

correct level when base

clamp touches table top

INCRA TS-LS Owner’s Manual

5

Custom Setups

Short vertical leg

FIG. 7

Tighten rail

mounting

bolts

Push rail against

short vertical leg

and tighten rail

mounting bolts

Rail mounting bolt

Rail

Slide stop positioner and base clamping

knob assemblies onto the rails

Base clamping knob - Add a

3

⁄

16

” thick nylon washer to each of

(4) base clamping knobs and loosely attach a

3

⁄

8

–16 dual pilot

rectangular nut. The flat side of the rectangular nut should face the

knob. Thread a

3

⁄

8

–16 x

3

⁄

8

” set screw into the remaining hole on

each rectangular nut. Slide the base clamping knob assemblies

onto the right hand end of each rail as viewed from the operator’s

side of the table saw. Do not tighten set screws or knobs at this

time. See Fig. 8.

Stop positioner - Add a

3

⁄

8

” flat washer to each of (4)

3

⁄

8

–16 x

1

⁄

2

”

hex bolts, then loosely attach a

3

⁄

8

–16 rectangular nut. Slide one

stop positioner into each end of both rails, capturing the rectangular

nut in the T-slot as shown. Do not tighten bolts at this time.

6

FIG. 8

Assembly

Do not tighten

fasteners at this time

3

⁄

8

” flat

washer

3

⁄

8

– 16 x

1

⁄

2

”

hex bolt

Base clamping knob

3

⁄

16

” thick

nylon washer

3

⁄

8

– 16 x

3

⁄

8

” set screws

3

⁄

8

– 16

rectangular

nut

3

⁄

8

– 16 dual pilot

rectangular nuts

T-slot

Left end of rail

Right end

of rail

FIG. 6

Set final rail position

45” (72” rails)

65” (92” rails)