Warranty, Auxiliary fence mounting, Maintenance – INCRA TS-LS Table Saw Fence User Manual

Page 12

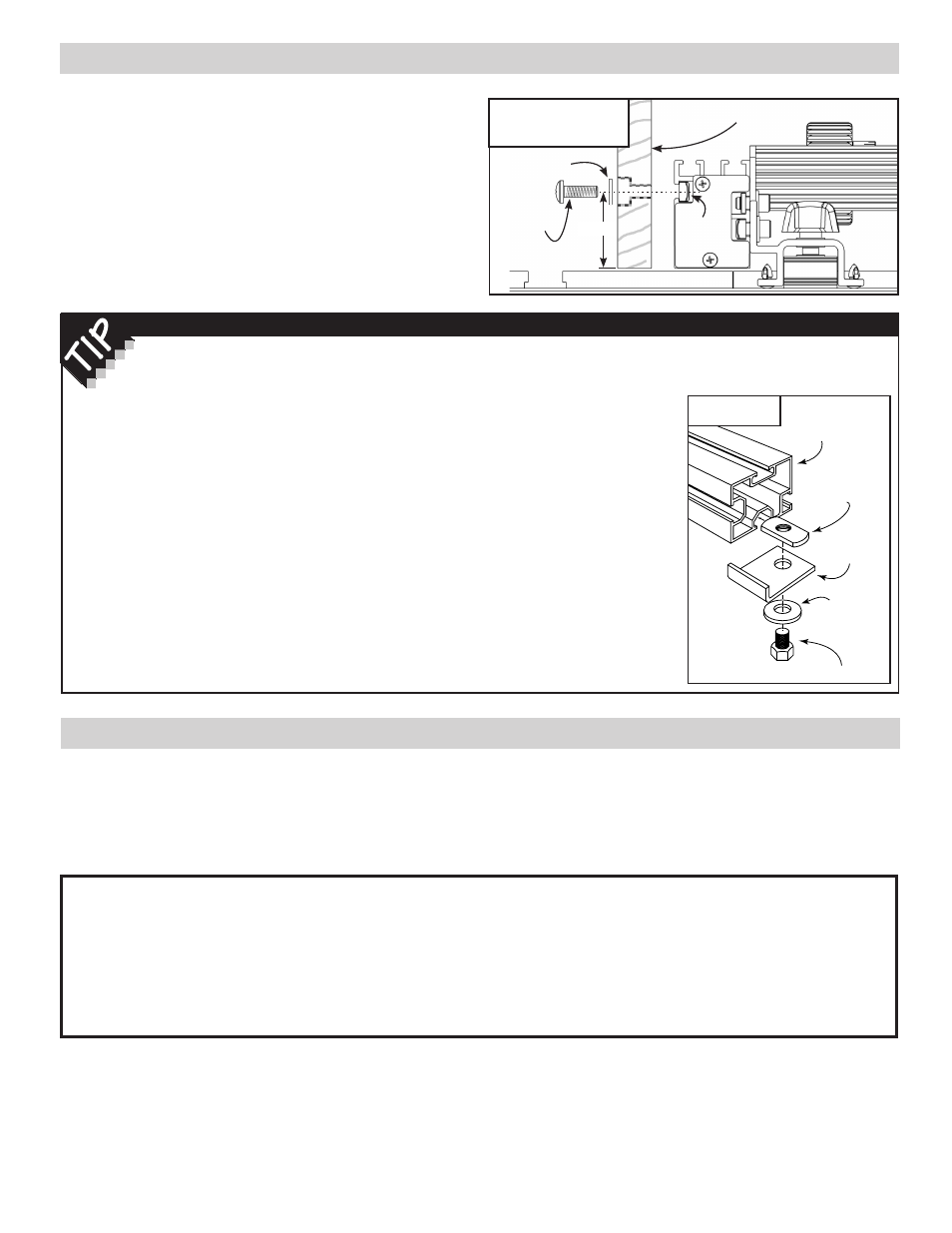

AuXILIARY FENCE MOuNTING

For some cutting operations, you may wish to add a wooden

auxiliary fence to the front face of your TS-LS fence. A

T-slot is provided for mounting the auxiliary fence using

1

/

4

-20 mounting screws, washers, and hex nuts. Drill and

counterbore your wooden fence to recess the screw heads

and capture the nuts in the T-slot as shown in Fig. 29. Hole

centers should be located 1

3

/

4

” from the bottom edge of the

wooden fence. T-slots in the top of the fence are provided to

attach hold downs or other user-made fixtures. Use

1

/

4

-20

fasteners and hex nuts for these T-slots as well.

Made in America by:

Taylor Design Group, Inc.

P.O. Box 810262

Dallas, Texas 75381

Tel: (972) 242-9975

Fax: (972) 243-4277

Web Site: www.incra.com

Printed in the U.S.A. © 2003 Taylor Design Group, Inc.

INCRA is a registered trademark of Taylor Design Group, Inc.

fig. 29

Auxiliary fence mounting

Wooden auxiliary fence

1

/

4

” flat

washer

1

/

4

– 20

screw

1

/

4

–20

hex nut

WARRANTY

Taylor Design Group, Inc. warrants this product for one year from date of purchase. We will repair any defects due

to faulty material or workmanship, or at our option, replace the product free of charge. Please return the failing

component only, postage prepaid, along with a des cription of the problem to the address below. This warranty does

not apply to parts which have been subjected to improper use, alteration, or abuse.

MAINTENANCE

Your TS-LS is designed to give many years of virtually

maintenance-free operation. In fact, just keeping your

TS-LS clean is all you need to do to keep the tool in top

shape. Occasionally, remove the carriage from the base

and brush or blow out any sawdust or debris that may

have accumulated. Use a toothbrush to clean the teeth on

the lead screw on both the carriage and the base. A light

application of paste wax to the top of the rails from time to

time will keep the rails smooth and clean.

10/12

Included with your TS-LS package you’ll find

the

Floating Stop Hardware Pack B-05. These

stops mount to the bottom T-slot on the rails and are

used when you want to set stop positions for the base

assembly anywhere between the fixed left or right hand

stops located on the sides of the rails.

One reason for a mid-range stop position might be to

provide a single position for the base assembly where

one could access both the saw blade and the left hand

router table extension wing. Such a setup would provide

about 15”-16” of range at the table saw function and

up to 30” of travel for the router function. To install the

stops, place a washer on each end of the (2)

3

/

8

-16 x

1

/

2

” hex bolts. Insert the bolt through the hole in the stop

and loosely thread on the rectangular nut. Slide the nut

into the bottom T-slot from the right end of each rail. See

Fig. 30. After positioning the LS along the rails at the

desired location, slide the floating stops up to the base

clamps and tighten the bolts.

Once positioned, you

can still slide the base

assembly past the stops

if necessary by first

disengaging the fence

hooks and loosening the

(4) base clamp knobs, then

lifting the base assembly

just enough to clear the

stops as you slide the

base assembly forward or

backward.

fig. 30

12

INCRA Woodworking Tools & Precision Rules

Floating Stops

Floating

stop

3

/

8

– 16

rectangular

nut

Right hand

end of rails

3

/

8

” flat

washer

3

/

8

-16 x

1

/

2

” hex bolt

1

3

/

4

”