Micro adjusting your fence position, Zeroing the fence to your cutter – INCRA LS Positioner User Manual

Page 13

INCRA LS Positioner Owner’s Manual

13

Micro Adjusting your Fence

Position

The micro adjust feature of your LS Positioner allows for

precise positioning of the fence to any location between

the

1

/

32

” or 1mm incremental spacing of the lead screw.

You’ll find this feature extremely handy the next time

you need to widen a mortise by a hair for a great fitting

mortise and tenon joint. Use the micro adjuster for a

flawless fit when cutting grooves to accept inlay strips or

to loosen up a tight fitting tongue and groove joint. You’ll

find it especially useful for setup operations like “zeroing”

to your cutter, or “centering” for joinery. Here’s a step-by-

step look at operating your LS Positioner’s micro adjuster.

See

Fig. 29 as you follow the steps.

Set Carriage Clamp to Micro Adjust

Position

Lower the carriage clamp to completely unclamp the

carriage, then raise the carriage clamp to the center

position. This center position for the carriage clamp

softens the clamping pressure on the carriage to per-

mit movement during micro adjusting.

Micro Adjust the Fence Position

Rotate the red micro adjust knob located at the

forward end of the carriage. Turn the knob clockwise

to move the fence toward the cutter, or counterclock-

wise to move the fence away from the cutter. Ball

bearing engaged detents on the knob provide an

audible click for each

1

/

1000

” (1/20mm for metric

version) of fence movement.

lock the Carriage Clamp

Pull the carriage clamp up to lock the carriage

in place. Gauging the distance moved when micro

adjusting is easy. A full turn of the knob equals

1

/

32

”

(1mm for metric version.) For smaller adjustments,

the black dial is marked in

1

/

1000

” (1/40mm) increments.

After micro adjusting, you can re-zero the dial to the

pointer by rotating the dial (not the red knob) with

your fingers. See

Fig. 30.

Zeroing the Fence to Your Cutter

In order to ensure accurate cutting results from any

fence for general purpose routing, the fence must first

be “zeroed” to the cutter,

Fig. 31. To zero your fence,

unlock the carriage clamp and slide the fence up to

the edge of the cutter. Sight down the length of the

fence to check for a gap between the fence and the

cutter. Fine-tune any remaining distance by micro

adjusting the fence position. When the gap of light

disappears, the cutter will be “zero” distance from

the fence. Check to make sure that the router bit is

safely centered in the opening in the fence. Return the

carriage clamp to the locked position, then slide the

measuring scale to read 0” under the hairline cursor.

1

2

3

For a truly precise “zeroed” setup, follow

the instructions above, then move the

fence to a scale reading of ¼” and make a

test cut on a piece of scrap stock. (Make sure

the scrap stock has a straight and square fence

bearing edge.) Use a pair of machinist calipers to

measure the distance between the groove and the

edge of the board. If it does not measure exactly

.250”, just use the micro adjuster to accurately fine-

tune the remaining distance.

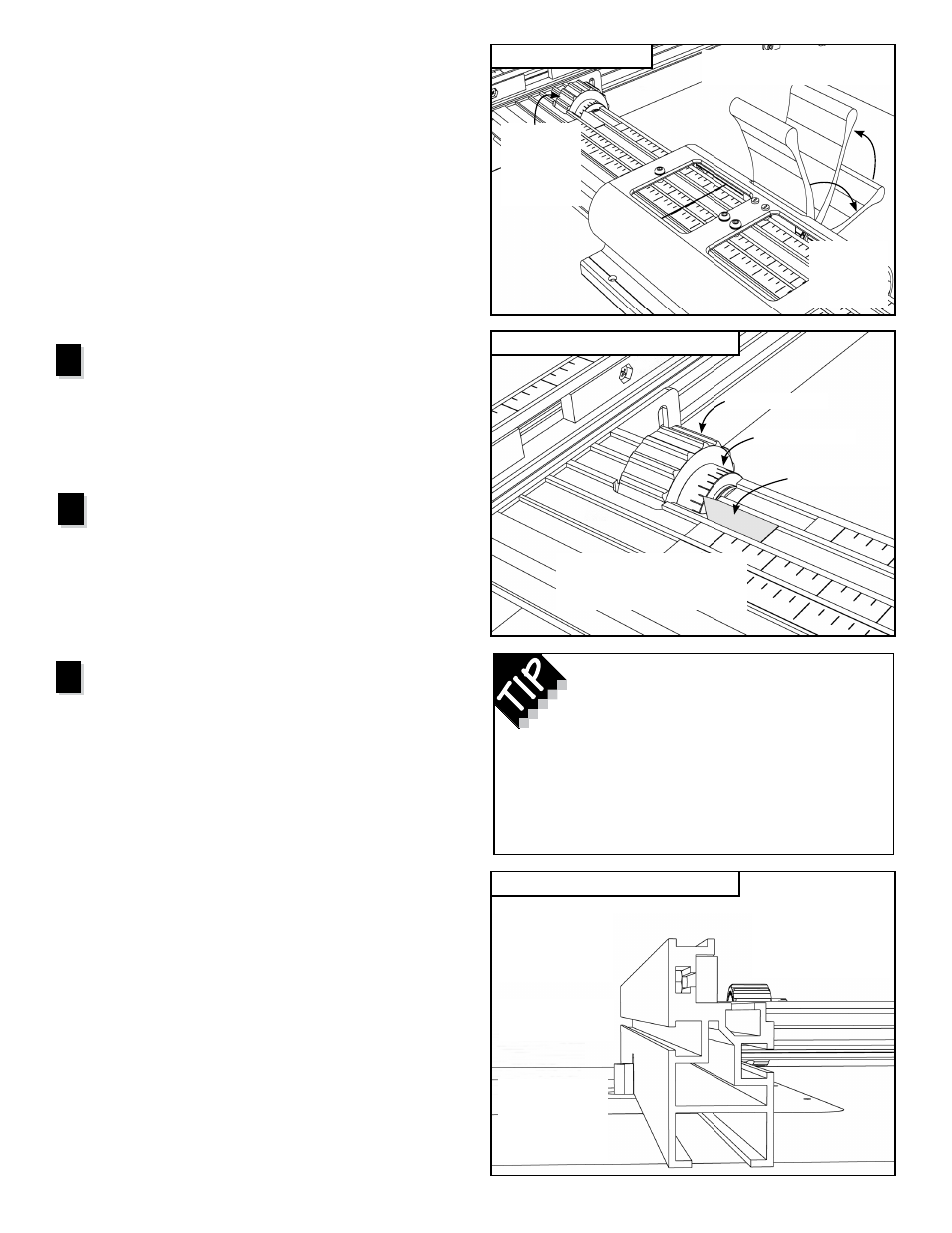

FIg. 29

Micro adjusting

Fourth: Pull

carriage clamp

up to “locked”

position

Third: Turn

micro adjust

knob to fine-

tune fence

position

First: Push

carriage

clamp down

to “unlock”

Second: Pull carriage clamp up to

center “micro adjust” position

FIg. 30

Re-zeroing the micro adjust dial

After micro adjusting, rotate the

dial (not the knob) to align the

zero with the pointer

Micro adjust knob

Micro adjust dial

Pointer

FIg. 31

Zeroing the fence to your cutter

First: “Unlock”

carriage clamp and

slide fence up to

cutter

Second: Raise carriage

clamp to “micro adjust”

position and rotate

micro adjust knob until

gap between fence and

cutter disappears

Third: Lock carriage

clamp

Fourth: Slide

stainless steel

primary scale to

read 0” under the

hairline cursor

0