Operation, Zeroing the shop stop, Moving to a new scale setting – INCRA LS Positioner User Manual

Page 12

12

INCRA Woodworking Tools & Precision Rules

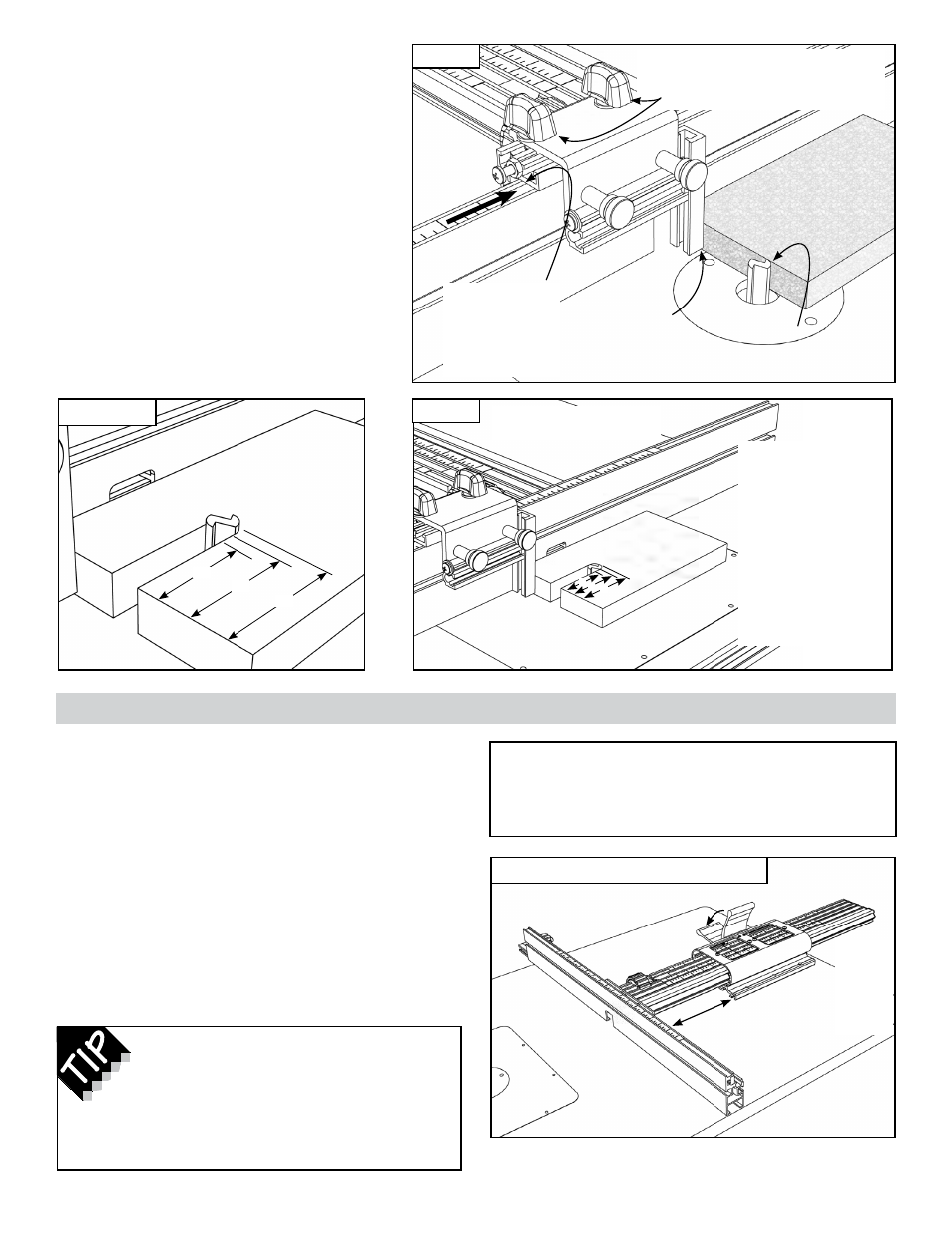

Zeroing the Shop Stop

In order for your INCRA Shop Stop to

accurately locate your work piece for a

cut, you must first “zero” your Shop Stop

to the cutter and position the sliding scale

on your fence. For most applications at

the router table you will be using your

Shop Stop on the outfeed fence to limit

the length of a cut relative to the front end

of a board. Follow the steps detailed in

Fig. 26

to zero to your cutter.

Once the Shop Stop is zeroed to the

router bit as shown in Fig. 26, you now

have the choice of setting the sliding

scale on your INCRA Fence to one of

three initial positions. See Fig. 27 and

Detail 27A

.

FIg. 26

Fourth: Slide scale

to read directly

under end of stop

cap. Use one of the

initial scale settings

from Fig. 27

Second: Clamp Shop Stop

to fence with the vertical

stop arm as close as

possible to the board

First: Slide square cut

board to contact “high

spot” on the router bit

Third: Loosen black thumbscrews

1

/

8

turn

and micro adjust until stop arm touches

end of board. Retighten thumbscrews.

FIg. 27

Slide scale on fence to one of

three initial positions

A: Slide scale to 0” for

a direct readout of

dimension “A”

(Total length of cut)

B: Slide scale to “minus

½ of bit diameter”

for direct readout of

dimension “B”

C: Slide scale to “minus

bit diameter” for direct

readout of dimension “C”

C B A

OPerAtIOn

Moving to a new Scale Setting

Moving the fence to any new scale setting is

just as easy as moving any other fence you’ve

used before. Push the carriage clamp down to

unlock the carriage, then slide the fence as you

sight through the hairline cursor. When you see

your measurement under the hairline cursor,

pull the clamp up to the locked position, Fig. 28.

Remember that the LS Positioner will only clamp

every

1

/

32

” or 1mm with the metric version, so

don’t try to clamp in between scale marks. It just

won’t work!

Although the clamping pressure has

been factory adjusted, you may wish

to fine-tune the pressure to suit your

individual feel. If so, use the thin plastic

shims provided and follow the instructions

beginning on page 14.

FIg. 28

Moving to any new scale

setting

First: Unlock carriage clamp

Second: Slide fence as

you view scale through

hairline cursor

Third:

Return

clamp to

upright

“locked”

position

CAUTION: For your safety, keep your hands

behind the fence when moving to any new

scale setting.

DETAIL 27A

C

B

A