General Machine Products 70400 Apollo Cable Lasher User Manual

Page 14

14

Apollo Lasher

9. Raise the rear cable lifter by pushing up on the bottom of the lifter that

contacts the D shaft. The thumblatch doesn’t have to be activated to raise

the cable lifter.

10. Adjust the position of the vertical rollers so that they barely touch the

sides of the cable(s). This will have to be done as the bundle size changes.

See section 4.6 for more information on terminating lashing wire.

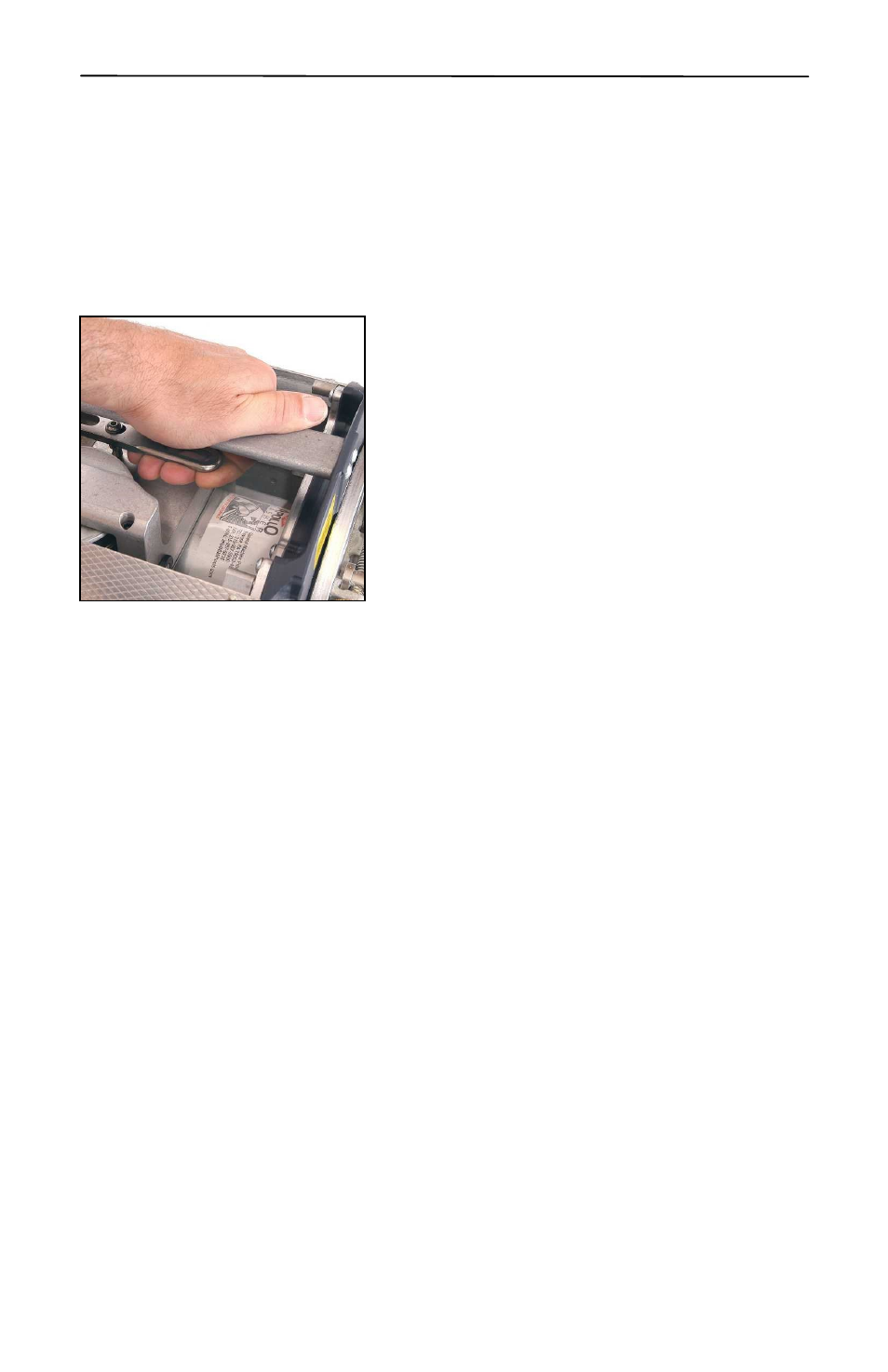

11. Now the final steps. Pull up on the han-

dle to de-clutch and disengage the drive

wheel to pull some lashing wire from the

lasher. Secure the lashing wire to the strand

by using a GMP D or E lashing wire clamp.

Attach the bridle assembly to the towing

eyes on the Apollo lasher and you are ready

to lash.

4.6 Lashing wire termination

4.6.1 General

A common cause of lashing wire failure is improper termination. The follow-

ing steps outline the suggested method for proper lashing wire termination.

1. Lashing wire termination should be accomplished and cable supports in-

stalled as soon as practical after the cable is placed.

2. Measurement marks made in making terminations should be made on the

strand rather than on the cable sheath. Avoid scoring the cable sheath with

the lashing wire end when terminating lashing wire.

3. Cable guards should be used to prevent abrasion of the cable sheath where

the separation is less than 1/2 inch between the cable and suspension

clamps.

While the D lashing wire grip and D and E lashing wire clamps may be used

on strand sizes up to and including 7/16 in (11mm) (16M) or larger, the discus-

sion on lashing wire termination will only cover the strand sizes of .25 to .38

in. diameter (6 to 10 mm) (6M, 6.6M and 10M), the only strand sizes compati-

ble with the Apollo lasher.

Figure 24