General Machine Products 15472 Fiber Optic Mid-Assist Capstan 25 in., 32 in. and 40 in. User Manual

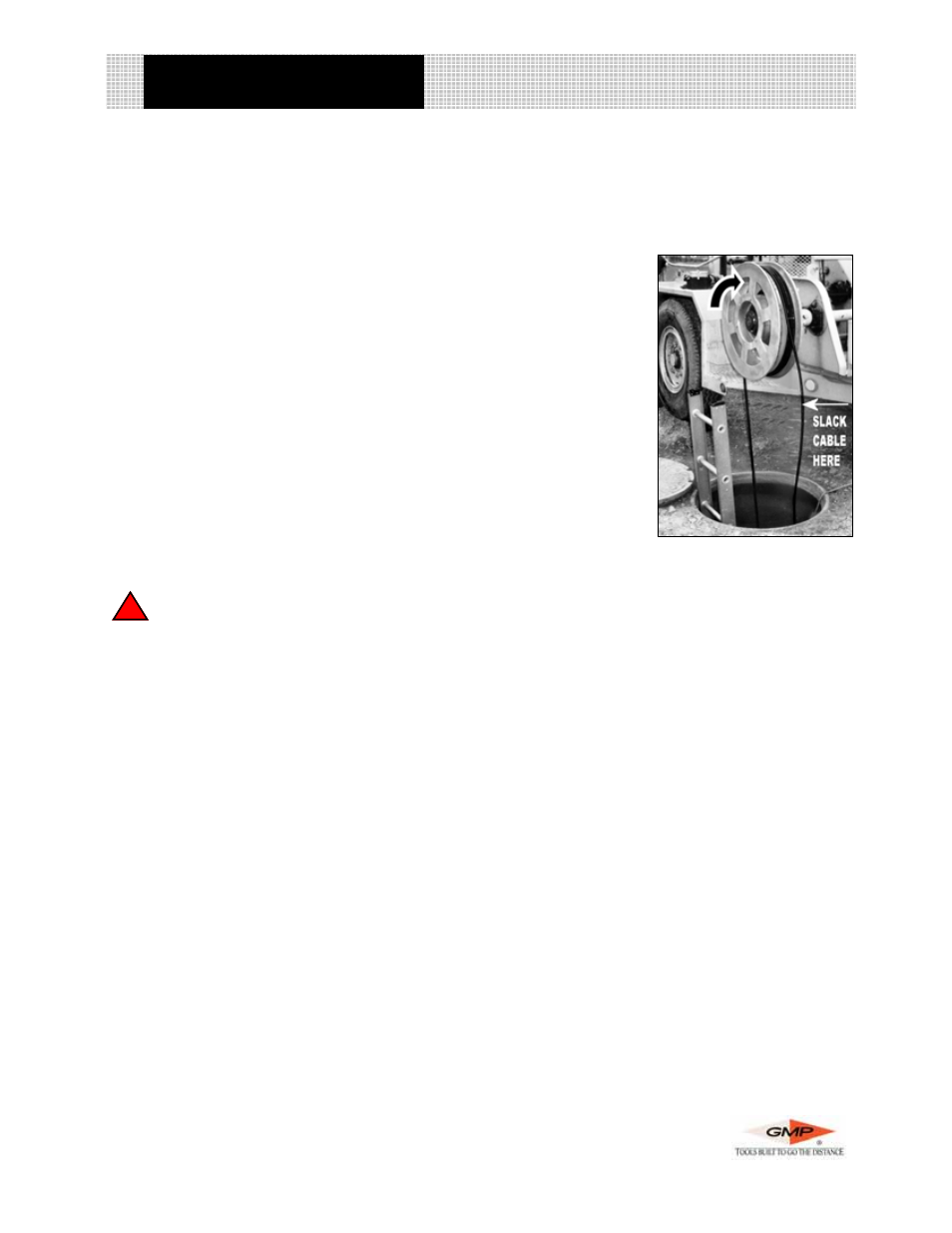

Fiber optic pulling capstans, How to use your new

Fiber Optic Pulling Capstans

Description & Use

Your new GMP Fiber Optic Pulling Capstan is a

versatile and highly productive tool for placing

fiber optic cable. It is based on GMP's accessory

approach to fiber cable placing that lets you use

your existing pulling equipment, winches and

capstan drives, without special modifications or

expensive new pulling equipment.

Virtually anywhere you have used a CR Collapsi-

ble Reel or RS Power Reel you can now use this

fiber puller. Its durable construction and mini-

mum number of components give it a remarkably

long, trouble-free service life. The large working

diameter of the capstan translates into good pull-

ing speed and you can pull with rope, tape, or pull

the fiber cable itself. This means that the Fiber

Optic Pulling Capstan can be used both as an end

puller or a mid-assist booster puller.

Any of these units can be easily mounted on a 2-

7/16 in. (62 mm) diameter drive shaft with either

a bayonet or a cross pin type of connection.

IMPORTANT PRECAUTIONS

Before you begin placing cable, you should be

completely familiar with the control and opera-

tion of the vehicle, power take-off, winch or cap-

stan drive controls and all of the other pulling

equipment you will be using. The operator should

never leave his position at the controls while the

pulling line is under load or the winch power

take-off is engaged. All members of the crew

along the entire length of the intended pull should

be in visual communication by hand signals or

voice communication at all times.

Make certain that all vehicles and trailers are se-

cured with wheel chocks. Make sure your work

area is properly posted with signs, flaggers and

other advance warning devices in accordance

with company practices. Federal, State and local

regulations for the protection of the crew and the

public. You'll find everything you need in our

Safety Catalog.

If you are pulling from a drum shaft extension on

a bed winch, de-clutch so that the drum is in free-

spool, wind all of the wire rope onto the drum and

secure it using a winch line holder. This will keep

the wire rope from spooling off the drum and be-

coming entangled.

Do not stand inside of angles formed by the pull-

ing line or cable. As much as possible, do not

stand where there is the danger of being struck by

the pulling line if it should fail or snag. Never

place hands on a moving pulling line. To prevent

entanglement in moving parts and possible seri-

ous injury, do not wear loose fitting clothing

when working around the winch, capstan, sheaves

and pulling line.

General Physical

Features

There are several models

of capstans available:

P/N 15470 P/N 15472 and

P/N 15479 each consist of

an aluminum alloy capstan

drum measuring 27-1/2 in.

(698 mm) outside flange

diameter and a 25 in. (635

mm) diameter X 5 in. (127

mm) wide working sur-

face. The capstan drum is

bolted to an inner hub and

drive spindle by means of

three 1/2 -13 x 1-1/4 in.

cap screws with 3/4 in. (19 mm) hex heads.

P/N 15470 is a capstan mounted directly to the

inner hub and drive spindle with no torque limit-

ing capability. With this unit the pulling tension

must be limited by means of a break-away swivel

or by limiting the hydraulic system pressure to

achieve a maximum allowable torque.

P/N 15472 is a capstan equipped with an integral

torque limiter between the driving spindle and the

inner hub. The torque limiter limits the pulling

tension to a calibrated maximum that has been set

at the factory to 600 pounds-force (2669 N).

P/N 15479 is a capstan equipped with an integral

torque limiter between the driving spindle and the

inner hub. The torque limiter limits pulling ten-

sion to a calibrated maximum that has been set at

the factory to 1000 pounds-force (4448 N).

P/N 70351 consists of an aluminum alloy capstan

drum measuring 34-3/4 in. (883 mm) outside di-

ameter and a 32 in. (813 mm) diameter X 7-1/2

in. (191 mm) wide working surface. The unit is

equipped with an integral torque limiter between

the driving spindle and the inner hub. The torque

limiter limits the pulling tension to a calibrated

maximum that has been set at the factory to 600

pounds-force (2669 N).

P/N 70381 is same as 70351, but provides pulling

tension of 750 pounds-force (3336 N).

!

How to Use Your New...