1a 1b – Flint & Walling 4 (10 cm) Stainless Commander S Series User Manual

Page 3

4

Copyright © 2014 Flint & Walling. All rights reserved.

5

Copyright © 2014 Flint & Walling. All rights reserved.

PREPARATION

SubMERSIblE CAblE ANd GROuNd wIRE

SElECTION

wARNING: Turn off power at the electrical

service box before starting installation.

Finding the Depth of Your Well:

1. Tie a small, heavy weight to the end of a cord

(make sure the cord is at least 350 ft. long). Lower

this weight into the well until it reaches the bottom.

Take up any slack and mark the string at ground

level. Pull the string from the well and measure

from the weight to your mark. This is the depth of

your well. Subtract 10 ft. from your well depth. See

catalog erformance charts to be sure pump is rated

for this depth.

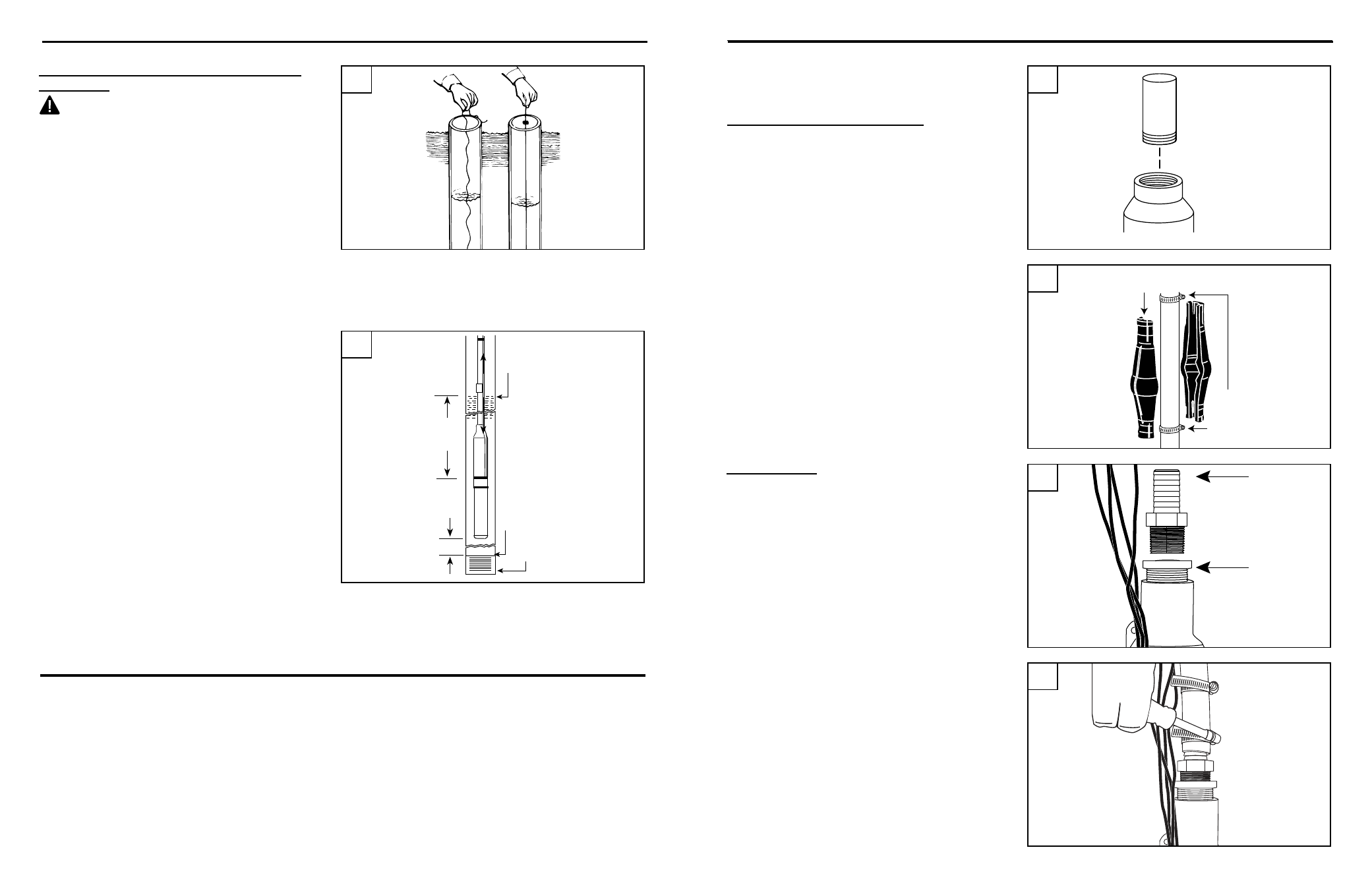

(Fig. 1)

NOTE: Schedule 80 PVC pipe is recommended. If you use black poly pipe, the pipe must be rated for 160 PSI

and be no longer than 200 ft.

NOTE: The pump must be assembled with piping on the ground before lowering into the well. Lay out all

necessary materials near the well.

NOTE: All threaded joints and connections should have thread tape applied, tightened securely with a pipe

wrench and then tightened an additional 1/4 turn.

Drawdown

Water Level

10 Ft. Min.

20 Ft.

Top of Well Screen

Bottom of Well

1

2

ASSEMblY

2. Drawdown is the lowest water level in the well

after the pump is turned on. If you know the

drawdown, the pump can be set 20 feet below this

level. However, the bottom of the motor should be

a at least ten feet from the top of the well screen.

(Fig. 2)

ASSEMblY INSTRuCTIONS

Follow step 1a and 1b below for Schedule 80 pipe

or step 2a and 2b for black poly pipe.

Schedule 80 pipe (recommended)

1a. Apply thread tape and then thread the pipe

directly into the pump discharge and tighten. For

1 in. pipe, you will also need a 1-1/4 in. x 1 in.

reducer bushing, not shown.

(Fig. 1a)

Schedule

80 Pipe

Submersible

Pump

Torque

Arrestor

1a

1b

black poly pipe

2a. Apply thread tape and thread a 1-1/4 in. male

barbed adaptor into the top of the pump and

tighten. If using 1 in. black poly pipe, install a

1-1/4 in. x 1 in. reducer bushing as shown.

(Fig.

2a)

IL1171

1-1/4 in.

male

barbed

adapter

1-1/4 in x

1 in.

reducer

bushing

2a

1b. Slide the two hose clamps packaged with the

torque arrestor over the end of a short piece

of Schedule 80 pipe (approximately 4 ft. long).

The pump will be easier to handle if a short

piece is installed first. Continue to Step 3.

(Fig. 1b)

IL1172

2b

2b. Clamp pipe onto barbed end of male adaptor

with two hose clamps.

(Fig. 2b)