Flint & Walling 4 (10 cm) Stainless Commander S Series User Manual

Page 10

18

Copyright © 2014 Flint & Walling. All rights reserved.

19

Copyright © 2014 Flint & Walling. All rights reserved.

ElECTRICAl HOOKuP FROM THE HOuSE TO PuMP ANd PRESSuRE TANK

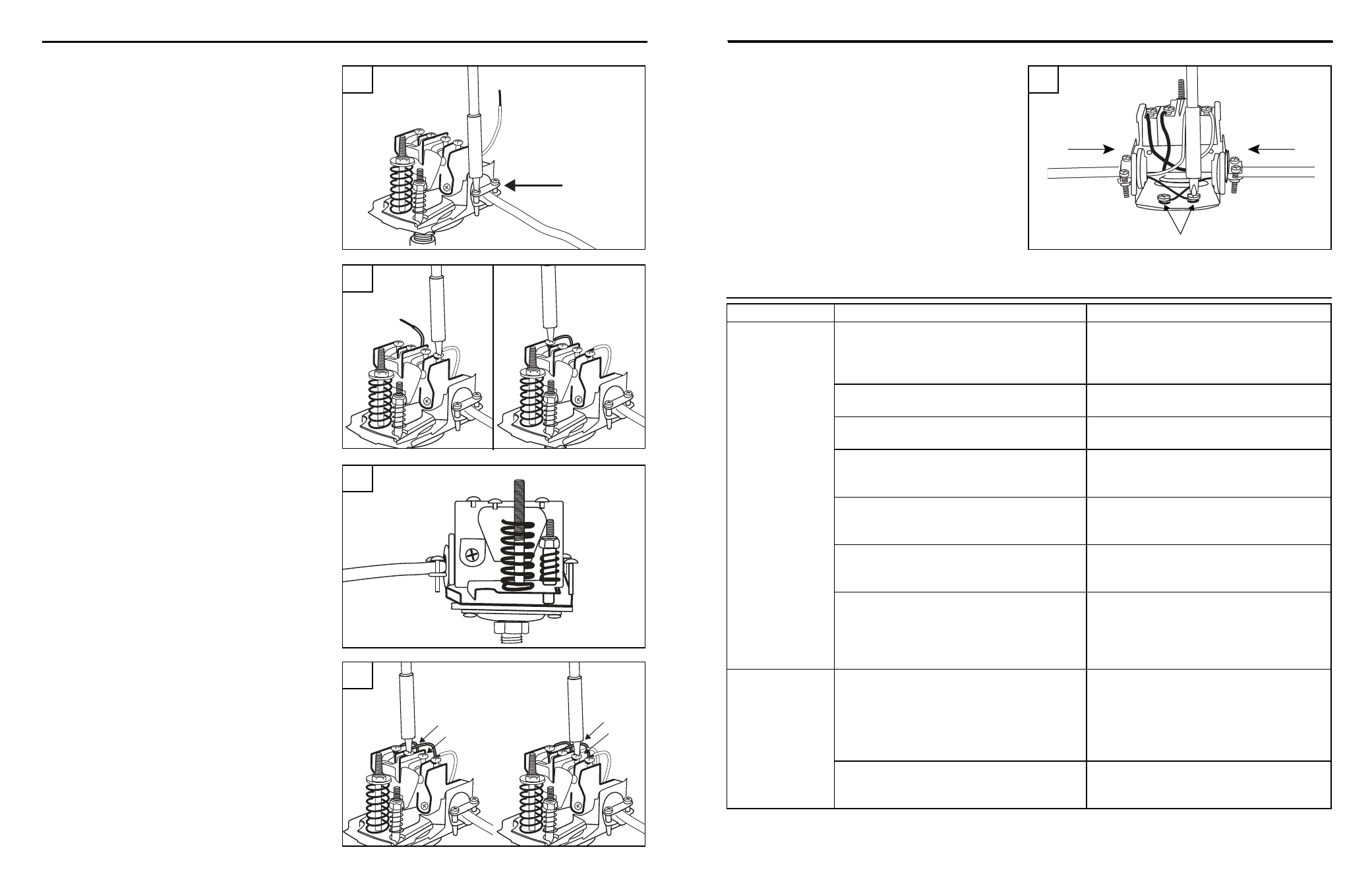

10. Thread the cable from the house electrical

service through one of the holes in the side

of the pressure switch and tighten down the

electric wire strain relief.

CAuTION: Do not crush wire. (Fig. 10)

11. Connect the two wires from the house electrical

service to the outside pressure switch terminals

(L1 and L4).

(Fig. 11)

ElECTRICAl HOOKuP FROM THE HOuSE TO PuMP ANd PRESSuRE TANK

12. Thread the cable from the control box through

the remaining hole in the side of the pressure

switch and tighten down the electric wire strain

relief.

CAuTION: Do not crush wire. (Fig. 12)

13. Connect the two wires from the control box to

the inside pressure switch terminals (L2 and

L3).

(Fig. 13)

14. Connect green ground wires from the control

box cable and the house electric cable to the

two ground screws on base of pressure switch.

Replace switch cover.

(Fig 14)

IL1162

L4

L1

Strain Relief

L4

L1

L4

L1

10

11

IL1165

12

L3

L2

IL1167

L2

L3

13

IL1182

Ground Screws

From

Control Box

From

Power Source

14

TROublESHOOTING

Problem

Possible Cause

Corrective Action

Fuses blow

1. Incorrect voltage at motor

1. Check for correct wire size. Replace

undersize wire. Check line voltage,

contact power company if voltage is

incorrect

2. Defective fuse box or incorrect fuses

2. Inspect fuse box wiring and correct.

Install the proper fuses

3. Defective pressure switch

3. Replace pressure switch or clean

contacts

4. Control box malfunction

4. See control box checking and repairing

procedures. Replace defective

components

5. Defective drop cable insulation

5. Check drop cable insulation resistance.

Pump must be pulled to replace

defective cable

6. Motor malfunction

6. Check motor winding resistance. Pump

must be pulled to replace defective

motor

7. Pump malfunction

7. If all above checks are good, then pump

is probably bound. Pump must be

pulled. Check for sand or pump shaft

misalignment. Correct well condition if

sand is the problem

Motor won’t start.

Fuses don’t

blow

1. No power to start motor

1. Check voltage at line side of fuse box.

Contact power company if no power is

reaching box. Check voltage at load

side of fuse box and at other control

devices in circuit. Make necessary

corrections

2. Defective drop cable or motor

2. Check motor winding resistance. Pump

must be pulled to replace defective

cable or motor