Flint & Walling 4 (10 cm) Stainless Commander S Series User Manual

Page 11

20

Copyright © 2014 Flint & Walling. All rights reserved.

21

Copyright © 2014 Flint & Walling. All rights reserved.

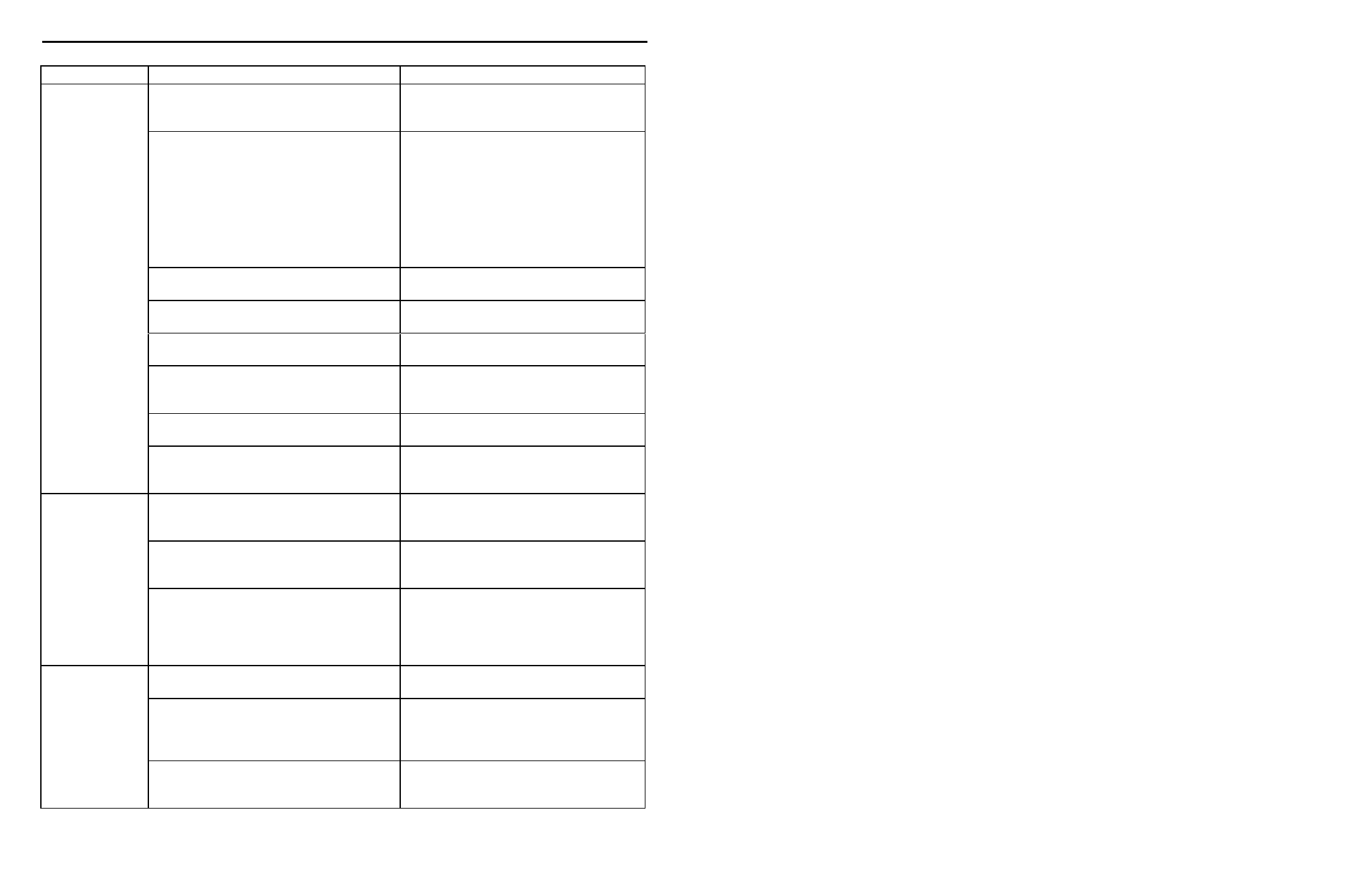

TROublESHOOTING

Problem

Possible Cause

Corrective Action

Motor runs, but

delivers little or

no water

1. Air locked pump

1. Normal delivery may resume if water

pump is started and stopped at one

minute intervals

2. Gas or air in well water

2. Connect hose to service valve. Run

water thru hose submerged in water in

clear jar. Observe for air bubbles from

hose outlet. If tank is standard type, the

air volume control may be defective -

replace; otherwise, have well checked

for proper water level as pump may be

drawing air. Lower pump and/or correct

well condition

3. Low water level in well or pumping too

much from well

3. Throttle pump with gate valve. Lower

pump setting if depth of well is adequate

4. Defective or improperly installed check

valve

4. Pump must be raised to replace or

reinstall correctly

5. Leak in drop pipe damaged section

5. Raise pump, check pipe for leak and

replace

6. Pump inlet screen blocked

6. Raise pump and clean screen. Verify

that well is clean. Reset pump at less

depth if possible

7. Worn pump

7. Pull pump and replace damaged

components

8. Broken pump shaft or motor shaft or worn

coupling

8. Pull pump, inspect shafts and coupling

for damage. Replace defective

components

Pump operates

properly, but

won’t shut off

1. Pressure switch

1. Readjust switch to lower shut off

pressure setting, clean contacts or

replace switch

2. Low water level

2. Throttle pump outlet at gate valve or

readjust pressure switch to lower shutoff

pressure setting

3. Leak in drop pipe or worn pump

3. Throttle pump output at gate valve or

readjust pressure switch to lower shut

off pressure setting. If pump does not

shut off, pump must be raised and

defect repaired

Pump starts too

often

1. Pressure switch

1. Readjust switch to wider operating

pressure limits; replace defective switch

2. Air volume in tank incorrect

2. Check pressure in tank. Set at 2 lbs.

below turn on pressure of the pressure

switch. i.e. 30/50 pressure switch should

have tank pressure of 28 lbs.

3. Check valve defect or leak in drop pipe

3. Throttle pump output at gate valve. If

pump does not shut off, pump must be

raised and defect repaired