Operating instructions, Installation, Operation – FasTest EZ Series User Manual

Page 2

OPERATING INSTRUCTIONS

Roseville, MN

Ph: 1-800-444-2373

Fax: 651-645-7390

www.fastestinc.com

WP127 Rev A 5/2/2014

Installation:

Connect hose/fitting securely to the termination port of the connector.

1/8” NPT tighten to a maximum torque of 12 ft-lbs.

1/4

” NPT tighten to a maximum torque of 25 ft-lbs

3/8” NPT tighten to a maximum torque of 40 ft-lbs

Operation:

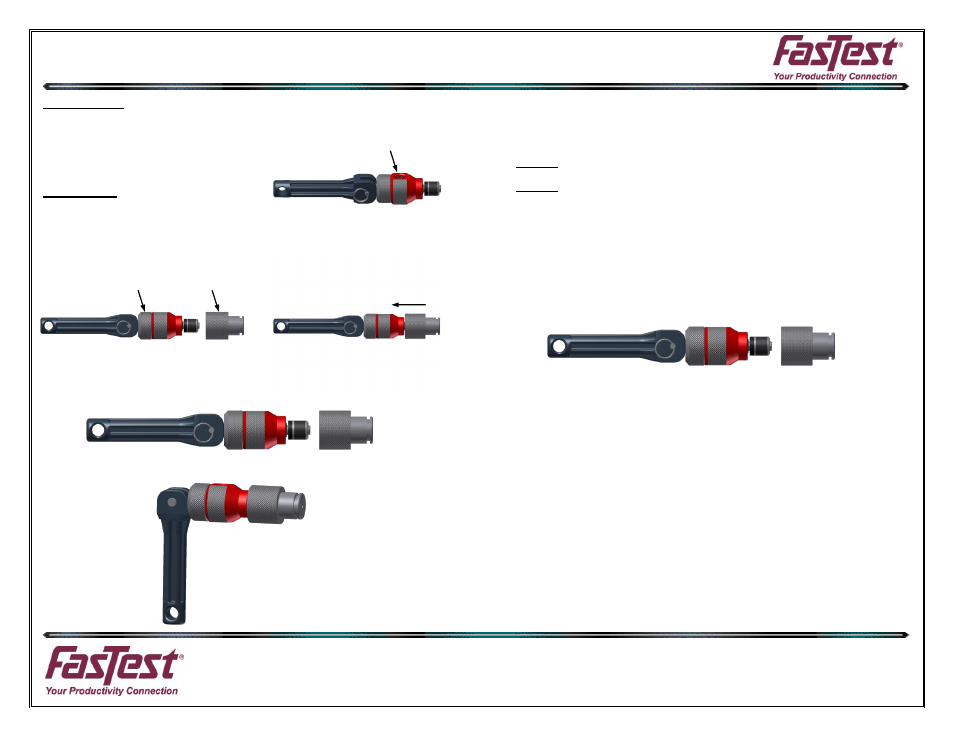

Connecting Action:

1.

Depending on the bore size the seals may need to be preloaded to

properly fit and seal the bore after handle has been rotated. To pre-load

prior to insertion into bore, spin back cap in or out in this horizontal

position and it will compress the main seal(s).

2. Insert sealing end into port and rotate handle 90° degrees in either

direction.

CAUTION NOTES;

CAUTION: The maximum rated pressure is stamped on the connector body. Be-

fore using, verify that this pressure rating is within your working pressures.

WARNING: Tug on the connector to assure proper engagement and gripping

before introduction of pressurized media.

DO NOT force connector onto test part when connecting. Forcing the connector

will result in poor sealing and possible leakage.

DO NOT spin test piece on seal once lever has been rotated 90° degrees.

3. Activate test media through connector termination port.

Disconnecting Action:

1. Deactivate test pressure. (DO NOT ROTATE LEVER UNTIL TEST

PRESSURE HAS BEEN DEACTIVATED).

2. Rotate lever to the horizontal position and remove from test piece.

Pressure Ratings:

1. When testing smooth bore ports, maximum test pressure is 50psi.

Test Piece

Test Piece Inserted

TERMINATION

PORT

Back Cap