Twin), Operating instructions safety switch stp-tw – EUCHNER STP-TWxxx (Twin) User Manual

Page 5

Operating Instructions Safety Switch STP-TW...

(Twin)

EUCHNER GmbH + Co. KG Kohlhammerstraße 16 D-70771 Leinfelden-Echterdingen Tel. +49/711/75 97-0 Fax +49/711/75 33 16 www.euchner.de [email protected]

Subject to technical modifications; no r

esponsibility is accepted for the accuracy of this information. © EUCHNER GmbH + Co. KG

100047-05-02/12 (translation of the original operating instructions)

Protection Against Environmental Influences

A lasting and correct safety function requires that the

actuating head must be protected against the

penetration of foreign bodies such as swarf, sand,

blasting shot etc.

Electrical Connection

When choosing the insulation material and wire

for the connections, pay attention to the over-

temperature in the housing (depending on the

operating conditions)!

Only switching contacts marked with the

positively driven NC contact symbol

are to

be used for the safety circuit.

For switching elements with four positively dri-

ven NC contacts only the contacts 21-22 and

41-42 are actuated on activating and de-

activating the guard locking. In applications with

potentially hazardous states (e.g. overtravelling

movements), contact 21-22 and/or 41-42 must

always be integrated into the safety circuit.

For STP-TW with plug connector:

For use and applications as per the requirements of

, a class 2 power supply or a class 2 transformer

according to UL1310 or UL1585 must be used.

Connection cables for safety switches installed at

the place of use must be separated from all moving

and permanently installed cables and un-insulated

active elements of other parts of the system which

operate at a voltage of over 150 V. A constant

clearance of 50.8 mm must be maintained. This does

not apply if the moving cables are equipped with

suitable insulation materials which possess an

identical or higher dielectric strength compared to

the other relevant parts of the system.

The operating voltage for the interlocking solenoid

must match the value on the rating plate (e.g. U

S

=

AC/DC 24 V).

f

Break out the required entry opening.

f

Fit the cable gland with the appropriate degree of

protection.

f

For pin assignment see Figure 3.

f

Tighten the screws with a torque of 0.5 Nm.

f

Check that the cable entry is sealed.

f

Close the cover and screw in position.

Functional Check

Warning! Danger of fatal injury as a result of faults

in installation and functional check.

Before carrying out the functional check, make

sure that there are no persons in the danger

area. Observe the valid accident prevention

regulations.

After installation and any fault, the safety function must

be fully checked. Proceed as follows:

f

Mechanical function test

The actuator must slide easily into the actuating head.

Close the safety guard several times to check the

function.

f

Electrical function test

1. Switch on operating voltage.

2. Close all safety guards.

Guard locking by solenoid force:

¨

Activate

guard locking.

f

The machine must not start automatically.

f

It must not be possible to open the safety guard.

3. Enable operation in the control system.

f

It must not be possible to deactivate the guard

locking as long as operation is enabled.

4. Disable operation in the control system and

deactivate guard locking.

f

The safety guard must remain locked until there is

no longer any risk of injury.

f

It must not be possible to start the machine as long

as the guard locking is deactivated.

Repeat steps 2 - 4 for each safety guard.

Inspection and Service

If damage or wear is found, the complete switch

and actuator assembly must be replaced.

Replacement of individual parts or assemblies

is not permitted!

No servicing is required, but regular inspection of

the following is necessary to ensure trouble-free long-

term operation:

f

correct switching function

f

secure mounting of components

f

dirt and wear

f

sealing of cable entry

f

loose cable connections or plug connectors.

Note:The year of manufacture can be seen in the

bottom, right corner of the rating plate.

Exclusion of Liability under the Following

Conditions:

f

if the unit is not used for its intended purpose

f

non-compliance with safety regulations

f

non-compliance with safety regulations

f

failure to perform functional checks.

EC declaration of conformity

The manufacturer named below herewith declares that

the product fulfills the provisions of the directive(s)

listed below and that the related standards have been

applied.

EUCHNER GmbH + Co. KG

Kohlhammerstraße 16

70771 Leinfelden-Echterdingen, Germany

Directives applied:

f

Machinery directive 2006/42/EC

Standards applied:

f

EN 60947-5-1:2004 + Cor.:2005 + A1:2009

f

EN 1088:1995+A2:2008

Leinfelden, July 2010

Dipl.-Ing. Michael Euchner

Director

Duc Binh Nguyen

Authorized representative empowered to draw up

documentation

The signed EC declaration of conformity is included

with the product.

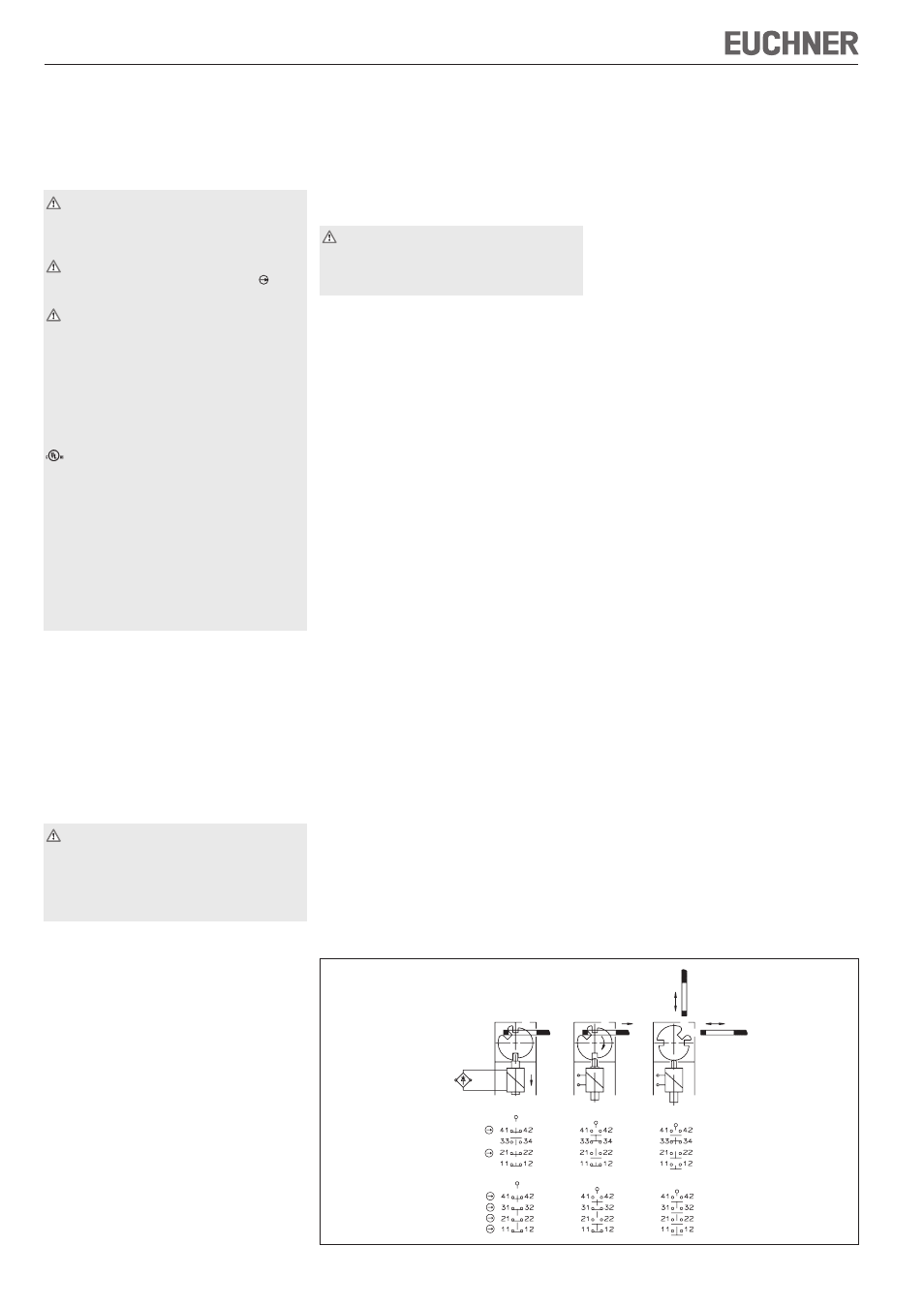

Figure 3: Switching elements and switching functions

E1

E2

E1

E2

v

h

E1

E2

Door closed

Door closed

Door open

and locked

and not locked

Type

STP-TW3-2131..

STP-TW4-2131..

STP-TW3-4141..

STP-TW4-4141..