Twin), Operating instructions safety switch stp-tw – EUCHNER STP-TWxxx (Twin) User Manual

Page 4

Operating Instructions Safety Switch STP-TW...

(Twin)

Correct Use

Safety switches series STP-TW...

(Twin) are

electromagnetic interlock devices with guard locking.

In combination with a separating safety guard and

the machine control, this safety component prevents

the safety guard from being opened while a dangerous

machine movement is being performed.

For the control system, this means that

f

starting commands which cause hazardous

situations must become active only when the safety

guards are in protective position and the guard

locking is in locked position.

The locked position of the guard locking must be

released only when the hazardous situation is no

longer present.

Before safety switches are used, a risk assessment

must be performed on the machine in accordance

with

f

EN ISO 13849-1, Safety of machinery. Safety related

parts of control systems. General principles for

design

f

EN ISO 14121, Safety of machinery. Risk

assessment. Principles

f

IEC 62061, Safety of machinery – Functional safety

of safety-related electrical, electronic and

programmable electronic control systems.

Correct use includes compliance with the relevant

requirements for installation and operation, particularly

f

EN ISO 13849-1, Safety of machinery. Safety related

parts of control systems. General principles for

design

f

EN 1088, Safety of machinery. Interlocking devices

associated with guards. Principles for design and

selection

f

EN 60204-1, electrical equipment of machines

Important:

f

The user is responsible for safe integration of the

device in a safe overall system. For this purpose

the overall system must be validated, e.g. in

accordance with EN ISO 13849-2.

f

If the simplified method according to section 6.3

EN ISO 13849-1:2008 is used for validation, the

Performance Level (PL) may be reduced if several

devices are connected one after the other.

f

If a product data sheet is included with the product,

the information on the data sheet applies in case of

discrepancies with the operating instructions.

Safety Precautions

Safety switches fulfill a personal protection function.

Incorrect installation or tampering can lead to severe

injuries to personnel.

Safety components must not be bypassed

(bridging of contacts), turned away, removed or

otherwise rendered ineffective.

On this topic pay attention in particular to the

measures for reducing the possibility of bypassing

according to EN 1088:1995.A2:2008, sec. 5.7.

The switching operation may only be triggered

by actuators specially provided for this purpose

which are permanently connected to the

protective guard.

Mounting, electrical connection and setup only

by authorized personnel.

Function

Safety switches series STP-TW...

(Twin) have two

actuator heads. They permit the simultaneous locking

or unlocking of two movable safety guards. Both

actuators must be inserted in order to activate guard

locking.

The safety switch permits the locking of movable

safety guards.

In the switch head there is a rotating cam that is

blocked/released by the guard locking pin. The guard

locking pin is moved on the insertion / removal of the

actuator and on the activation / deactivation of the

guard locking. During this process the switching

contacts are actuated.

If the cam is blocked, the actuator cannot be pulled

out of the switch head

¨

guard locking active.

Actuator Version

Actuator

S for safety switches STP-TW... without

insertion funnel.

Actuator

L for safety switches STP-TW... with insertion

funnel.

Version STP-TW3...

(Guard locking by spring force)

The guard locking pin is held in the locked position by

spring force and released by electromagnetic

actuation. The spring interlock guard locking functions

in accordance with the closed-circuit current principle.

The safety guard cannot be opened immediately in

the event of interruption of the solenoid power supply.

Version STP-TW4...

(Guard locking by solenoid force)

This type must be used only in special cases

after strict assessment of the accident risk!

The safety guard can be opened immediately in

the event of interruption of the solenoid power

supply!

The guard locking pin is held in the locked position by

electromagnetic force and released by spring force.

The guard locking operates in accordance with the

open-circuit current principle.

f

Closing safety guard and activating guard locking

The guard locking pin is released by insertion of the

two actuators into the safety switch.

STP-TW3...: The guard locking pin is moved to locked

position by spring force.

STP-TW4...: The guard locking pin is moved to locked

position when the solenoid operating voltage is

applied.

The safety contacts are closed.

f

Deactivating guard locking, opening safety guard

STP-TW3... (with door monitoring contact): The guard

locking pin releases the cam when the solenoid

operating voltage is applied.

For switching function see Figure 3 column 2

Door

closed and not locked

The actuator can be removed.

On the removal of the actuator, the door monitoring

contact switches and signals that the safety guard is

open (see Figure 3 column 3,

Door open).

STP-TW4... (with door monitoring contact): The guard

locking pin releases the cam when the solenoid

operating voltage is switched off.

For switching function see Figure 3 column 2

Door

closed and not locked

The actuator can be removed.

On the removal of the actuator, the door monitoring

contact switches and signals that the safety guard is

open (see Figure 3 column 3,

Door open).

Mechanical Release

In the event of malfunctions, the guard locking can

be released with the mechanical release irrespective

of the state of the solenoid (see Figure 4).

If the switch has a mechanical key release (optional),

the guard locking can be retained in the „not locked“

position (see Figure 1). Accidental locking in, for

example, of maintenance personnel is then prevented.

f

Actuating mechanical release

1. Unscrew locking screw.

2. Using a screwdriver, turn the mechanical release

by around 180° in the direction of the arrow

3. Return the locking screw to its original position

and seal after use (for example with sealing

lacquer or using wire).

f

Actuating mechanical key release

1. Insert key in the key opening

2. Rotate key from pos.1 (normal operation) to pos.2

(locked)

3. Remove key

4. Return to original position after use

Indication

The position of the guard locking is indicated in the

window.

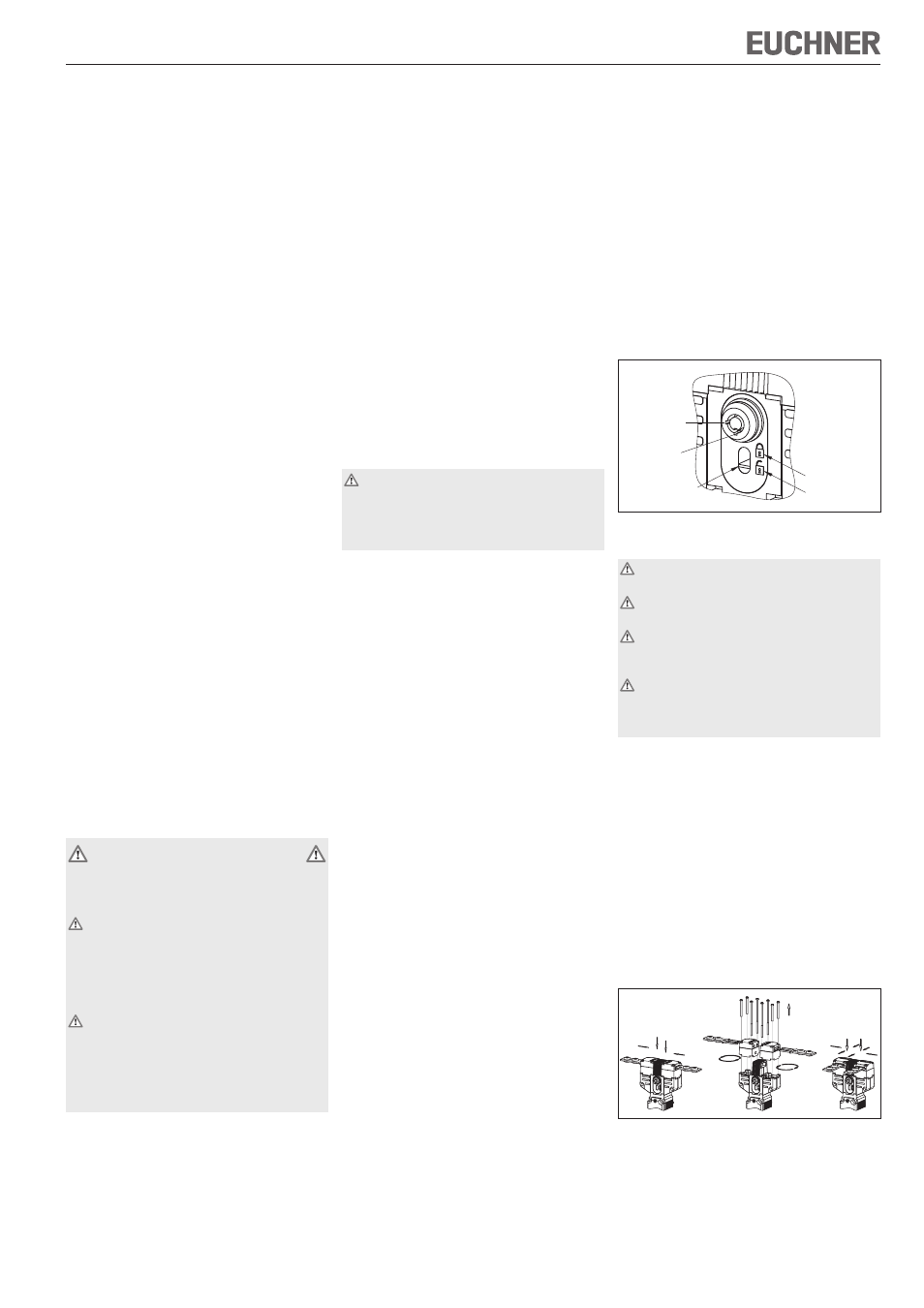

Figure 1: Mechanical key release and display

Installation

Safety switches and actuators must not be used

as an end stop.

Mount the safety switch only in assembled

condition!

To achieve the stated locking force, the mounting

holes on the switch head must also be used (see

figure 4).

Caution! Risk of burns due to high surface

temperature at ambient temperatures above 40

°C! Protect switch against touching by personnel

or contact with inflammable material.

Assemble the safety switch so that

f

access to the switch is difficult for operating

personnel when the safety guard is open.

f

it is possible to operate the mechanical release and

check and replace the safety switch.

f

the escape release can be actuated from the hazard

area.

Fit an additional end stop for the movable part of the

safety guard.

f

Insert the actuator in the actuating head.

f

Mount the safety switch positively.

f

Permanently connect the actuator to the safety

guard so that it cannot be detached, e.g. using the

enclosed non-removable screws, rivets or welding.

Changing the Actuating Direction

Figure 2: Changing the actuating direction

f

Remove the screws from the actuating head.

f

Set the required direction.

f

Correct arrangement of the screws (see figure 2).

f

Tighten the screws with a torque of 0.6 Nm.

f

Cover the unused actuating slots with the enclosed

slot covers.

Marking

Locked

Not locked

Pos. 2

(locked)

Pos. 1

(normal

operation)