Specification table – Enerpac STB-Series User Manual

Page 2

2

DANGER: Do not handle pressurized hoses. Escaping

oil under pressure can penetrate the skin, causing

serious injury. If oil is injected under the skin, see a

doctor immediately.

WARNING: Only use hydraulic cylinders in a coupled

system. Never use a cylinder with unconnected

couplers. If the cylinder becomes extremely

overloaded, components can fail catastrophically causing

severe personal injury.

WARNING: BE SURE SETUP IS STABLE BEFORE

LIFTING LOAD. Cylinders should be placed on a flat

surface that can support the load. Where applicable, use

a cylinder base for added stability. Do not weld or

otherwise modify the cylinder to attach a base or other support.

Avoid situations where loads are not directly centered

on the cylinder plunger. Off-center loads produce

considerable strain on cylinders and plungers. In

addition, the load may slip or fall, causing potentially dangerous

results.

Distribute the load evenly across the entire saddle

surface. Always use a saddle to protect the plunger.

IMPORTANT: Hydraulic equipment must only be

serviced by a qualified hydraulic technician. For repair

service, contact the Authorized ENERPAC Service

Center in your area. To protect your warranty, use only

ENERPAC oil.

WARNING: Immediately replace worn or damaged

parts by genuine ENERPAC parts. Standard grade parts

will break causing personal injury and property

damage. ENERPAC parts are designed to fit properly and

withstand high loads.

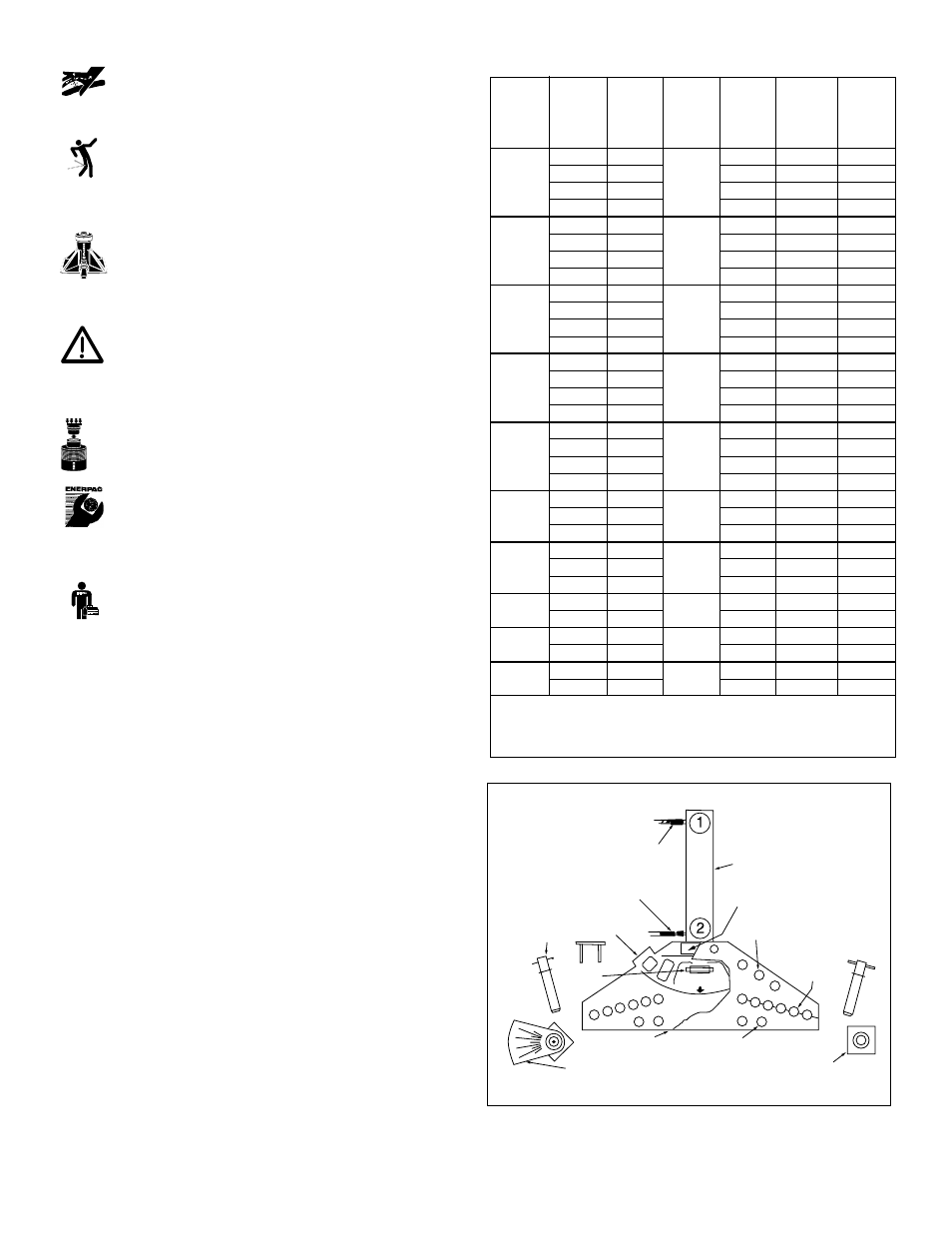

3.0 SPECIFICATIONS (see Specification Table)

4.0 BENDER ASSEMBLY (see Figure 1)

1.

Thread hydraulic cylinder into cylinder support block on

bending frame.

2.

Attach hose(s) to pump valve. Connect hose (1) to cylinder

port (1); hose (2) to cylinder port (2). NOTE: hose (2) is used

with STB-202 series benders only.

3.

Select bending shoe for pipe to be bent. Each shoe is marked

for size and has an arrow, indicating the center point of bend

to be made.

4.

Insert and lock selected bending shoe on cylinder plunger

with U-shaped lock pin.

Figure 1, Bender Assembly

®

Hydraulic Hose (bend)

Bending

Shoe

Hydraulic hose (eject)

(STB202 series)

Pivot Pin

(2 req’d.)

Shoe

Locking Pin

Bender Frame

Optic Angle Gauge

Over-bend

Correction

Holes

Pivot Shoe

(2 req’d.)

Hydraulic Cylinder

Cylinder Support Block

Pipe Eject Holes

Pipe Bending

Holes

Nomenclature

Step A – Bender Assembly

Nominal

Wall

Schedule

Pipe STB-101

STB-101

STB-101

pipe

Thickness

Pipe*

Bend

1-2

size

Radius

One Shot

(outside ø)

1/2

-2

2

1/2

-4

1

1/4

-4

(in)

(in)

(in)

One Shot

Sweep

One Shot

.109

40

Yes

-

-

.147

80

Yes

-

-

.187

160

2

7/8

WS

-

-

.294

160

WS

-

-

.113

40

Yes

-

-

.154

80

4

Yes

-

-

.218

160

WS

-

-

.308

DEH

WS

-

-

.133

40

Yes

Yes

-

.179

80

Yes

Yes

-

.250

160

WS

WS

-

.358

DEH

-

WS

-

.140

40

Yes

Yes

Yes

.191

80

Yes

Yes

Yes

.250

160

WS

WS

Yes

.342

DEH

-

WS

WS

.145

40

Yes

Yes

Yes

.200

80

Yes

Yes

Yes

.281

160

WS

WS

Yes

.400

DEH

-

WS

WS

.154

40

Yes

Yes

Yes

.218

80

Yes

Yes

Yes

.343

160

-

WS

Yes

.203

40

-

Yes

Yes

.276

80

-

WS

Yes

.375

160

-

WS

Yes

.216

40

-

Yes

Yes

.300

80

-

WS

Yes

.226

40

-

Yes

Yes

.318

80

-

WS

Yes

.237

40

-

Yes

Yes

.337

80

-

-

Yes

*Schedule pipe: 40=standard; 80=extra heavy; 160=double extra heavy (mild

steel pipe only)

DEH=double extra heavy (slightly thicker than 160);

WS=can be bent by moving pivot shoes to the holes for the next large pipe size.

1

⁄

2

(.840)

2

7

⁄

8

5

1

⁄

8

4

6

7

⁄

16

7

5

⁄

16

8

5

⁄

16

9

1

⁄

2

11

1

⁄

4

15

1

⁄

2

17

3

⁄

4

3

⁄

4

(1.050)

1

(1.315)

1

1

⁄

4

(1.660)

1

1

⁄

2

(1.900)

2

(2.375)

2

1

⁄

2

(2.875)

3

(3.500)

3

1

⁄

2

(4.000)

4

(4.500)

Specification Table