Enerpac VE-Series User Manual

Page 3

3

plumb into a circuit. As mentioned earlier, it is up to the

end user to provide the wiring and controls for the valve

when ordered this way.

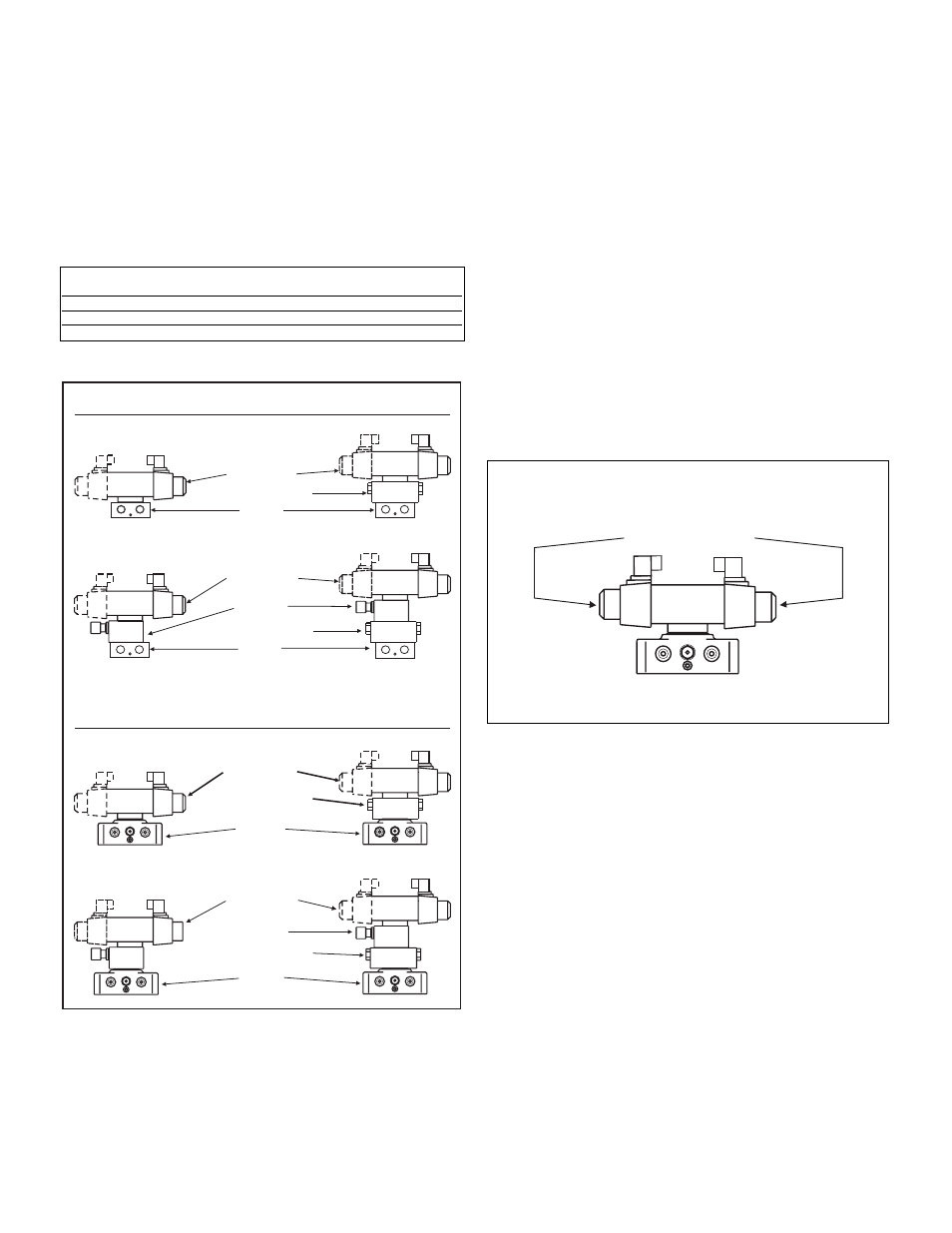

It is also possible to modify an existing valve to install

options after the initial purchase. In order to do this, the

correct bolt kit will be required. To determine which bolt kit

is correct for your valve, refer to Figure 2. These kits

replace the current bolts, which will be too short after the

addition of accessory valves.

Parts List for Figure 2

Figure 2, Valve Bolt Kits (Typical valve configurations)

6.0 OPERATION

All system components need to be rated for the maximum

pressure of the system, including hoses, fittings and

support equipment. The “VE” Valve Series are rated for

10,000 psi operating pressure.

NOTE: For all two-position, two-way valves, the tank

port MUST be plumbed when used as a dump or

unloading valve. This will allow residual pressure inside

the valve to vent back to tank.

7.0 INSTALLATION

1. If the valve is used in a remote application, connect all

pressure, tank and cylinder hoses to their prospective

ports, refer to Figure 2. Use proper thread sealant and

do not over tighten the pipe fittings.

2. Connect proper electrical controls using the supplied

VEP plugs. Make sure to supply correct voltage to

solenoid, based on information printed on the coil.

3. Three-position valves are spring biased to the center

position and will shift when power is supplied to the

coils.

4. To operate valve in the event of loss of electrical power,

a manual override is provided. Using a small diameter

punch, depress solenoid pin located in the center of

the solenoid core. See Figure 3.

Figure 3, Solenoid Pin

8.0 MAINTENANCE

1. Periodically check all hydraulic connections to be sure

they are tight. Loose or leaking connections may cause

erratic and/or total loss of pressure. Replace or repair

all defective parts immediately.

2. Periodically check the hydraulic oil level in your system.

Refer to oil filling instructions for your pump for

complete information.

3. Change hydraulic oil approximately every 250-300

hours of operation. In dusty or dirty areas, it may be

necessary to change oil more frequently.

9.0 TROUBLESHOOTING

Refer to Enerpac Service Instructions L1835.

Solenoid Pin

(Manual Override)

Solenoid

Operated Valve

Remote

Manifold

Locking Valve

Solenoid

Operated Valve

Pump

Manifold

Locking Valve

Solenoid

Operated Valve

Remote

Manifold

Adjustable

Relief Valve

Locking Valve

Solenoid

Operated Valve

Pump

Manifold

Adjustable

Relief Valve

Locking Valve

1

2

1

2

2

3

2

3

REMOTE OPERATED VALVES:

BOLT KIT OPTIONS

PUMP OPERATED VALVES:

Valve Part

Quantity

Description

Configuration

Number

1

BK1

1

Bolt Kit

2

BK2

1

Bolt Kit

3

BK3

1

Bolt Kit