Elkhart Brass 70133000 Electric Valves User Manual

Page 33

33

I FLANGE REQUIREMENTS

The 990 valves are designed for installation between ANSI Class 125/150 flat or raised faced flanges. Gaskets

are not required. Lined pipe, heavy wall pipe or flanges must have a minimum allowable inside diameter (See

appropriate SM0 drawing at back of manual for the specific valve’s “Q” dimension) at the centered body face

to clear the disc sealing edge when opening the valve.

II STORAGE

The valves should be stored on a pallet or “skid” in a clean, dry warehouse.

If the valves must be stored outside, the following applies:

- Valves must be kept off the ground and high enough to avoid standing water.

- Cover the valves with a water repellant cover (not supplied)

III INSTALLATION INSTRUCTIONS

The 990 valves are bi-directional and will control flow equally well in either direction. For the best results in

slurry service regarding sedimentation, position the valve assembly so that the valve stem is in the horizontal

position and the lower disc edge opens downstream. This will create a self-flushing effect, thereby extending

the service life of the valve.

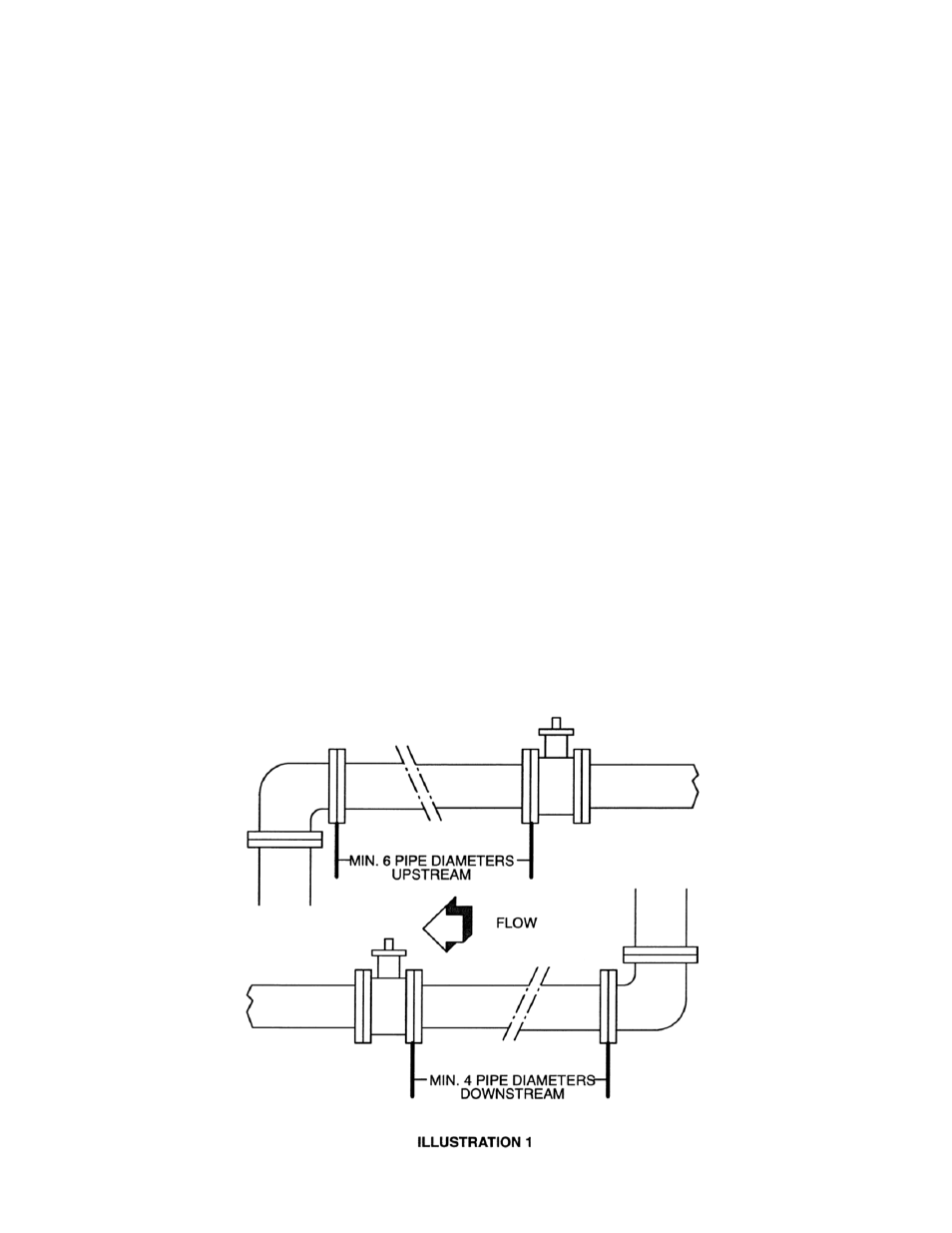

Consideration should be given to the location of the valves in the piping system. The valve should not be

placed too close to other valves, elbows, etc. as its performance may be affected. It is recommended the valve

have a minimum of six pipe diameters upstream (see Illustration 1) and four pipe diameters downstream

between it and other valves, elbows, etc. in the piping system. If the valve must be installed less than six pipe

diameters of a piping disturbance, the preferred orientation is mounting with the stem parallel to the inlet pipe

axis.