Iv installation – Elkhart Brass 70133000 Electric Valves User Manual

Page 10

10

IV INSTALLATION

CHECKS TO MAKE PRIOR TO INSTALLATION

To assemble the actuator onto the valve, proceed as follows:

- Check that the coupling dimensions of the valve flange and stem match the actuator’s coupling

dimensions.

- The electrical supply cables must be suitable for the power rating of the actuator (refer to the test

certificate delivered with the actuator, if available, or the actuator nameplate)

- Gather the necessary tools necessary to assemble the actuator to the valve and perform actuator setup.

- Lubricate the valve stem with oil or grease to facilitate assembly.

- Clean the valve flange. Remove anything that might prevent a perfect fit to the actuator flange,

especially all traces of grease or lubricant.

- Install the actuator onto the valve without forcing, using only the weight of the actuator. When the

actuator output shaft and the valve stem are connected, check that the holes of the valve flange match

the holes of the actuator mounting flange. If not, use the manual override to rotate the actuator until

the holes are aligned.

- Tighten the bolting evenly.

- If possible, operate the actuator with the handwheel to verify that it operates the valve smoothly.

If a long storage period has occurred, before installing the actuator:

- Check the status of the O-Ring seals.

- Check the installation of the plugs or cable connections on the cable entries.

- Check the integrity of enclosure covers.

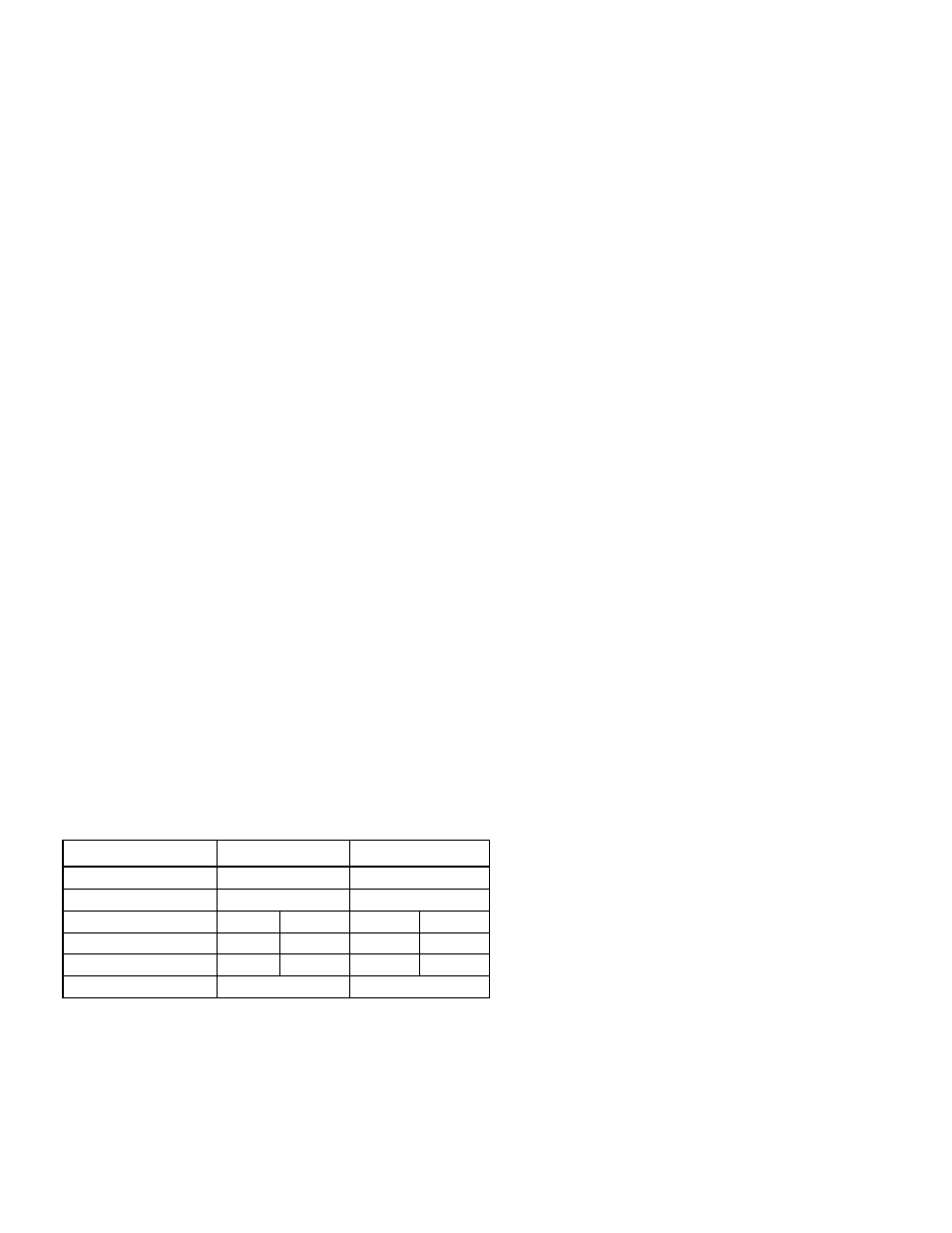

SPECIFICATIONS

FM Approved: Class 1, Zone 1, AEx/Ex de IIB T5

Class II, Division 1, Groups E, F, & G

Class III, T4

NEMA 4, 4X, & 6 – IP66/68

Power Requirement: 120/240 VAC, 50/60 Hz., 1-Phase

Valve Size

4”

8”

Actuator

EPI 2-E013

EPI 2-E025

Torque (in/lbs.)

1300

2500

Volts (AC)

120

240

120

240

Run Amps

1.10

0.70

1.60

0.95

Stall Amps

1.32

0.84

1.92

1.14

Weight (lbs.)

29

45

Ambient operating temperature:

-40°C to +65°C (-40°F to +149°F) with 80% humidity