Communication module and dcu wiring, Typical applications – Det-Tronics EA2100CG Eagle 2000 Communication Gateway User Manual

Page 23

COMMUNICATION MODULE

AND DCU WIRING

1.

Determine the best mounting locations for the

detectors. Whenever practical, detectors should be

placed where they are easily accessible for

calibration. Gas sensors should be pointing down to

minimize the accumulation of contaminants on the

filter and to ensure proper operation. Junction boxes

should be electrically connected to earth ground.

2.

Install the detectors as directed in the detector

instruction manual.

3.

Remove the cover from the junction box.

NOTE

Do not apply power to the system with the junction

box cover removed unless the area has been de-

classified.

4.

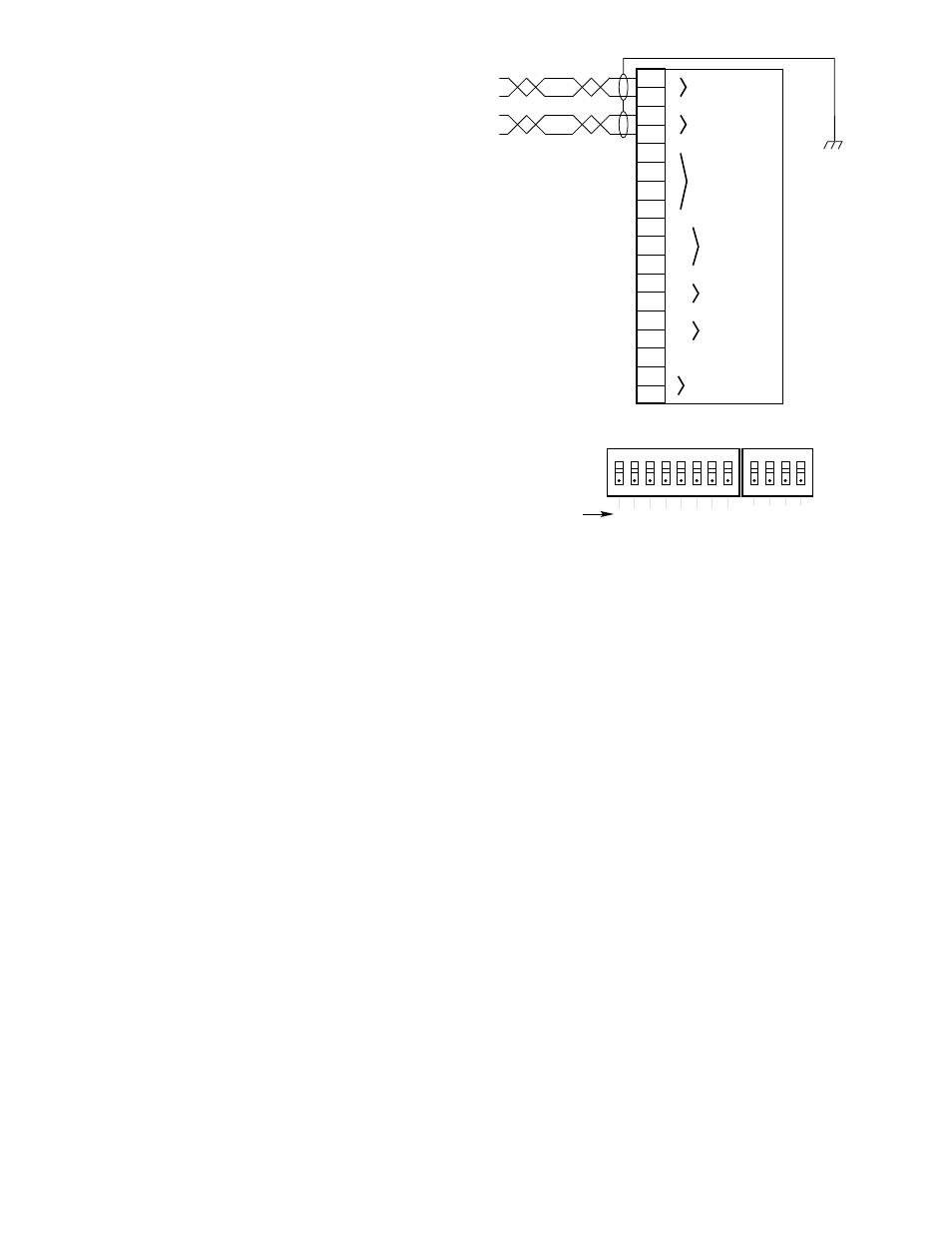

Connect external system wiring to the appropriate

terminals on the terminal block inside the junction

box. See Figure 16.

CAUTION

The gateway and communication modules will be

damaged if power is inadvertently applied to the

communication lines. The communication module

is protected against damage caused by switching

polarity of the power lines.

5.

Check the wiring to ensure proper connections,

then pour the conduit seals and allow them to dry (if

conduit is being used).

6.

Set the node address for the communication mod-

ule. Valid addresses are from 1 to 250. If the

address is set to zero or an address above 250, the

communication module will ignore the switch set-

ting. Duplicated addresses are not automatically

detected. All modules with the same address will

report on that address. The status word will show

the latest update, which could be from any of the

reporting modules at that address.

Address selection is accomplished by setting rocker

switches on the DIP switch assembly on the commu-

nication module circuit board. Each rocker switch

has a specific binary value (Figure 17). The node

address is equal to the added value of all closed

rocker switches. All open switches are ignored. For

example: for node No. 5, close rocker switches 1

and 3 (binary values 1 + 4); for node 25, close rock-

er switches 1, 4 and 5 (binary values 1 + 8 + 16).

7.

Install the electronic module inside the junction box.

Refer to Figure 7. Be sure that the ribbon cable is

properly connected.

8.

Inspect the junction box O-ring to be sure that it is in

good condition and properly installed. Lubricate the

O-ring and the threads of the junction box cover with

a thin coat of an appropriate grease to ease installa-

tion and ensure a water-tight enclosure. The recom-

mended lubricant is a silicone free polyalphaolefin

grease, available from Det-Tronics. If the installation

uses catalytic type combustible gas sensors, it is

imperative that lubricants containing silicone not be

used, since they will cause irreversible damage to

the sensor. Place the cover on the junction box.

Tighten only until snug. Do not over tighten.

TYPICAL APPLICATIONS

Figure 18 illustrates a typical system consisting of com-

munication modules used with a U8700 or U8800

Transmitter.

Figure 19 illustrates communication modules or DCUs

with toxic gas sensors.

Figure 20 shows communication modules or DCUs with

combustible gas sensors and transmitters. (A DCU has

the combustible gas transmitter mounted inside the

DCU enclosure.)

Figure 21 illustrates a typical system consisting of com-

munication modules with various flame detection devices.

19

95-8424

–

GROUND SHIELD

AT ONE END ONLY

A1599

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

A

A

B

B

22 AWG LEVEL 4

SHIELDED TWISTED PAIR

24 VDC POWER INPUT

NETWORK IN

NETWORK OUT

+

+

–

C

NO

NC

COM

IN 1

COM

IN 2

4 TO 20 MA

–

+

DIGITAL INPUT 1

DIGITAL INPUT 2

RELAY

DETECTOR POWER

(24 VDC)

1

2

3

4

5

6

7

8

1

2

3

4

1

2

4

8

16 32 64 128

OPEN

OPEN

}

LEAVE IN

OPEN POSITION

NODE ADDRESS EQUALS THE ADDED VALUE

OF ALL CLOSED ROCKER SWITCHES

A1557

BINARY VALUE

Figure 17—Communication Module Address Switches

Figure16—Wiring Configuration for Communication Module and DCU