Det-Tronics PIR9400 PointWatch Infrared Hydrocarbon Gas Detector User Manual

Page 9

7

95-8440

9.3

5. The sensor should be accessible for maintenance.

6. Excessive heat or vibration can result in premature

failure of any electronic device and should be

avoided if possible.

NOTE

For additional information on determining the

quantity and placement of gas detectors in

a specific application, refer to the article titled

“The Use of Combustible Detectors in Protecting

Facilities from Flammable Hazards” contained

in the Instrument Society of America (ISA)

Transaction, Volume

20

, Number

2

.

0

TO

100%

LFL LINEaRIzED OUTPUT OPTIONS

The PointWatch IR Detector is provided with five field

selectable “standard gas” signal processing program

settings. These settings create a linearized scale for

methane and other gases like ethane, propane, butane,

ethylene, or propylene, and are defined as linearized

PointWatch gas measurement outputs. This means

that the detector is capable of providing an analog

signal output that is directly proportional to the % LFL

concentration for these gases, provided the proper gas

setting has been selected, and the it has been calibrated

with the proper calibration gas type.

The PointWatch Detector is factory configured for

0

to

100%

LFL methane. To re-configure the detector for one

of the other gases, remove the electronic module from

the housing and select the desired gas by changing

the setting on the rotary gas selection switch. (Refer

to “Changing Linearized Output Gas Selection.”) The

detector must then be calibrated using a

50%

LFL

mixture of the selected gas.

NOTE

Failure to calibrate the device with a

50%

LFL

mixture of the selected gas will result in a sensor

fault and improper operation of the detector.

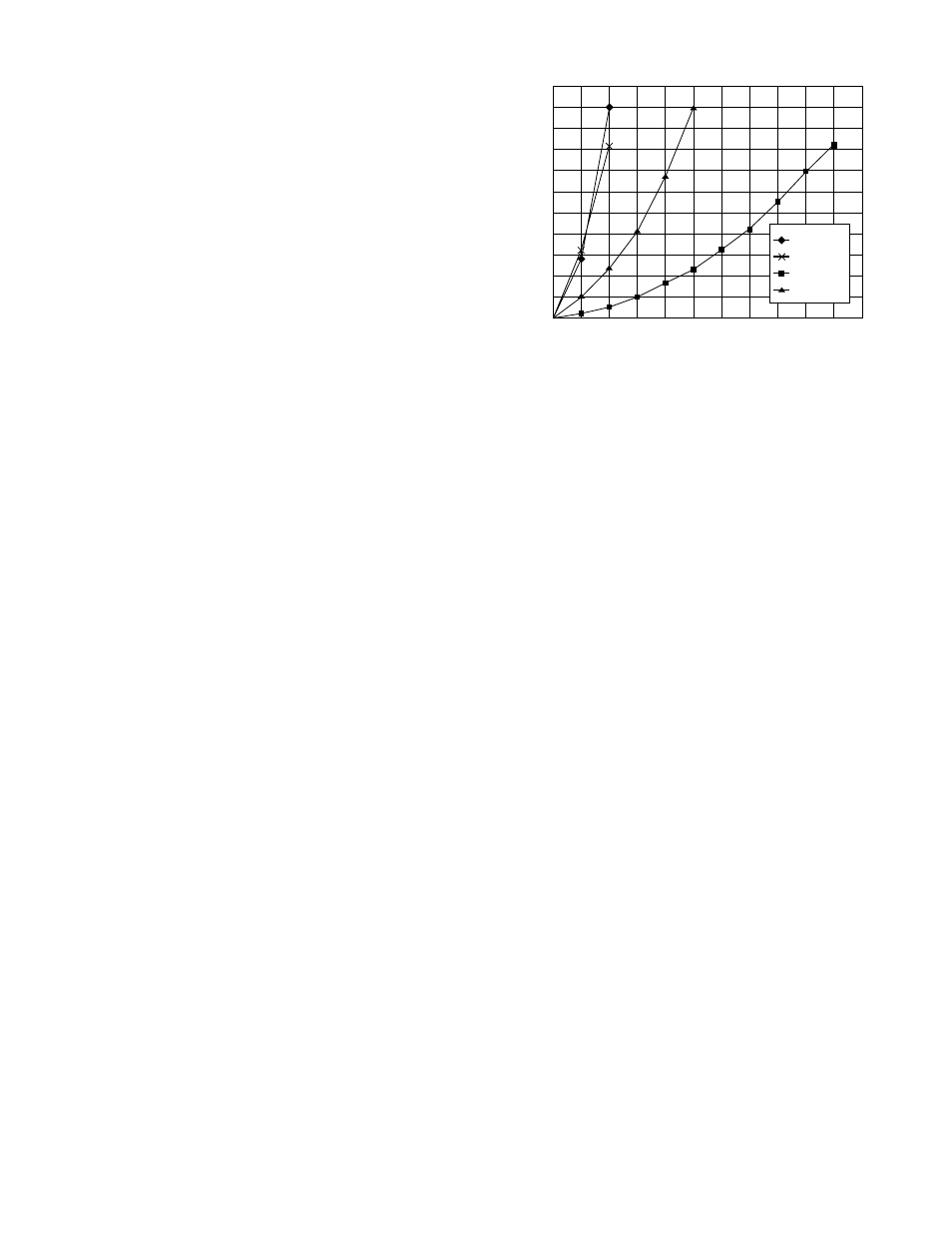

Response of Methane-Calibrated PointWatch Detector

(Factory Setting) to Other Gases

Figure

8

shows the signal output of a PIR

9400

that has

been properly calibrated for methane in response to

other gases. This data should be used as a reference

only. It is recommended to always calibrate the detector

with the type of gas to be detected.

PointWatch Model PIR

9400

Transfer Curves

The gas detector, when set for methane, provides

detection of other hydrocarbon vapors at higher LFL

readings (see Figure

8

). In addition to the standard gases

previously mentioned, the PointWatch Detector is capable

of detecting and measuring many other hydrocarbon

gases and vapors. Although linear detector outputs are

not offered for most of these gases, an accurate gas

concentration measurement can be made by using a

cross-reference data sheet known as a “transfer curve.”

(Available upon request.) The transfer curve data sheet

is always based upon the following:

1. The data applies to one specific gas/vapor type

only.

2. The data is collected at a specific test temperature.

(Significant differences in ambient hazard area

temperature as compared to test temperature may

impact transfer curve accuracy.)

3. The data compares actual hazardous gas

concentration in %LFL to the detector signal output

level, using all five standard gas settings.

The transfer curve data is then used:

1. To select the optimum detector standard gas

setting.

2. To select the appropriate setpoint levels for proper

alarm relay actuation. This will ensure that external

alarm response action occurs as required.

0

0

10

20

30

40

50

60

70

80

90

100

110

10

20

30

40

50

60

70

80

90

100

110

%LFL GAS

RESPONSE OF METHANE CALIBRATED POINTWATCH TO OTHER GASES

POINTW

A

TCH OUTPUT (% LFL)

ETHANE

PROPANE

ETHYLENE

PROPYLENE

C2019

Figure 8—Response of Methane-Calibrated

PIR9400 (Factory Setting) to Other Gases, at

Tamb = 25°C