Det-Tronics PIR9400 PointWatch Infrared Hydrocarbon Gas Detector User Manual

Page 10

8

95-8440

9.3

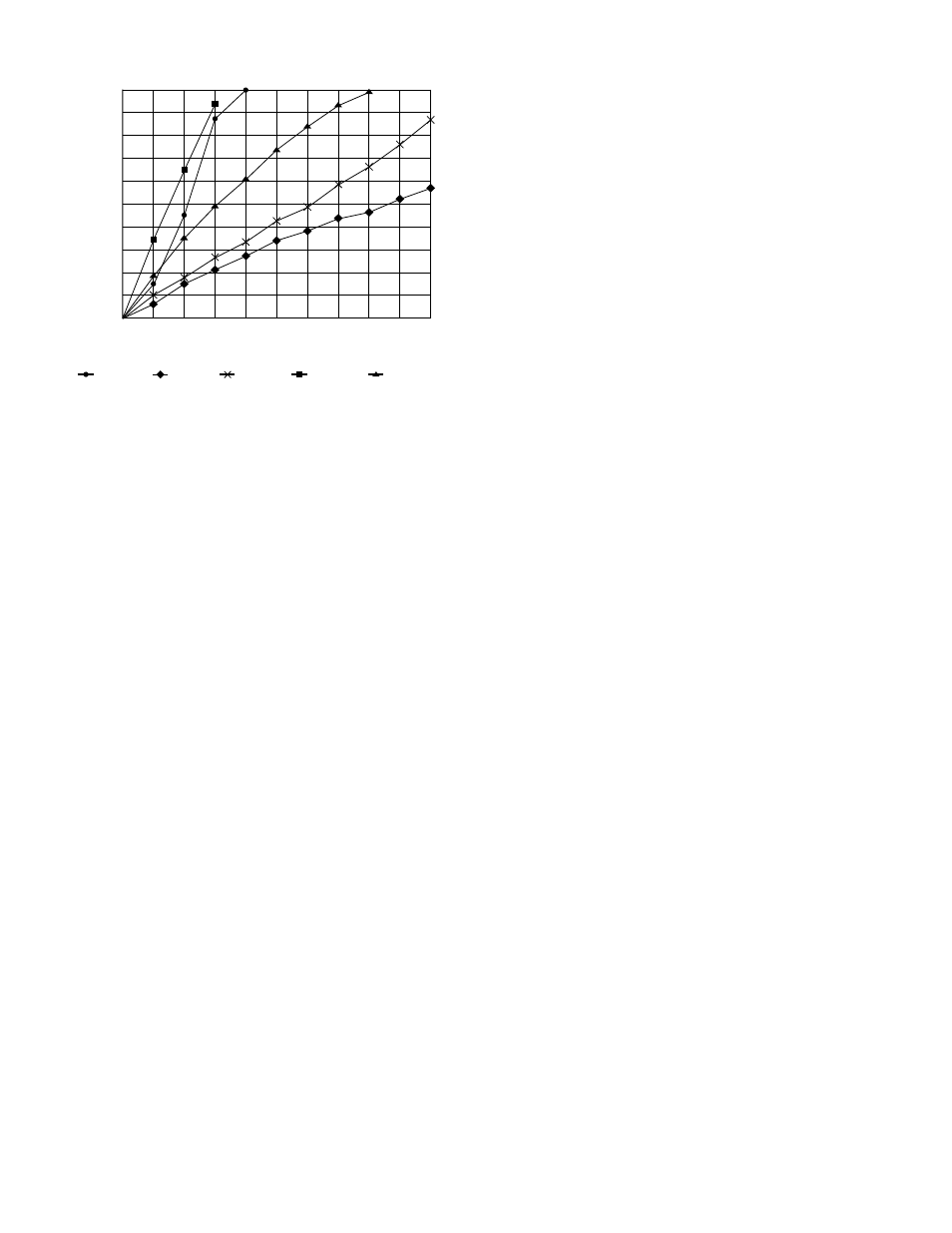

It is important to note that whenever using transfer curve

data, the Model PIR

9400

analog signal output and any

real-time visual display of that output (such as a digital

display or bar graph) will be offset by a value indicated by

the transfer curve data, and therefore must be externally

correlated by the viewer.

The transfer curve data sheet for the gas of interest

includes five different curves — one for each standard

linearized output setting. To select the appropriate setting

for the detector, find the curve that:

1. Provides the closest signal correlation across the

desired gas measurement range, and

2. Ensures that the offset in the PIR

9400

signal output

versus gas concentration is an over-reading, as

opposed to an unsafe under-reading.

Ideally, at

50%

of full scale PIR

9400

output (

12

ma

signal level) the detected gas level will equal

50%

LFL

gas concentration, and this relationship will remain

proportional throughout the gas measurement range. In

reality, however, transfer curve data is non-linear, and will

result in varying offset levels from proportional linearity

throughout the gas measurement range. Refer to the

example in Figure

9

.

To use the transfer curve data, find the concentration (in

% LFL) for the gas of interest on the horizontal axis of the

graph. Follow the vertical line up from that point until it

intersects with a gas response curve. From the point of

intersection, follow the horizontal line directly to the left

until it intersects with the vertical axis of the graph.

The point of intersection with the vertical axis represents

PIR

9400

output (

0-100%

LFL reading, or

4-20

mA

proportionally) in response to the actual gas concentration

at the installation using that particular linearized output

setting.

In the example for gasoline vapor detection (Figure

9

),

the recommended PIR

9400

standard gas setting and

calibration gas to use is propylene. When using this

setting and calibration gas type, at

50%

LFL gasoline

concentration, the PIR

9400

signal output will be

73%

(

15

mA). The propane and ethane settings would not

be recommended, since the signal output level is much

less than the actual gas concentration in the field. The

methane and ethylene settings are acceptable, but will

result in much higher readings than the gas level that is

actually present in the field.

Contact Detector Electronics Corporation (Det-Tronics

®

)

for additional information regarding PIR

9400

transfer

curves.

IR Module Removal and Gas Selection

iMPoRtant

Remove power before disassembling the

PointWatch Detector.

The electronics module of the PIR

9400

gas detector is

field-removable. There are four different revisions of the

IR module as listed below:

1. Aluminum type supplied with

6-32

captive flatblade

screws.

2. Stainless steel type supplied with

6-32

caphead

(Allen) screws (use

7/64

inch hex driver).

3. Aluminum type supplied with M

5

caphead (Allen)

screws.

4. Stainless steel type supplied with M

5

caphead

(Allen) screws.

The M

5

metric caphead screws were implemented as

a standard design beginning in mid-

2003

in order to

comply with ATEX product approval requirements. In

addition, the electronics mounting cover is factory-

tightened to a torque setting of

15

Newton-meters, and

requires the use of the cover removal tool. Do not use an

improper tool such as pliers or vise grip.

1. Completely loosen the captive screws on the flat end

of the detector using the appropriate tool (flatblade

screwdriver or Allen wrench) and slide off the weather

baffle assembly. See Figures

10

and

11

.

ETHANE

PROPANE

ETHYLENE

PROPYLENE

METHANE

0

0

10

20

30

40

50

60

70

80

90

100

10

20

30

40

50

60

70

80

90

100

GASOLINE %LFL

POINTWATCH GAS RESPONSE CURVES

POINTW

A

TCH OUTPUT (% LFL)

C2020

Figure 9—Example of a PIR9400 Transfer Curve for Gasoline,

at Tamb = 25°C