Det-Tronics PIR9400 PointWatch Infrared Hydrocarbon Gas Detector User Manual

Page 13

11

95-8440

9.3

The use of shielded cable in conduit or shielded

armored cable is recommended for optimum RFI/

EMI protection. In applications where the wiring cable

is installed in conduit, the conduit must not be used

for wiring to other electrical equipment. To assure

proper operation of the detector, the resistance of the

connecting wire must be within the specified limits. The

maximum distance between the detector and power

source is determined by the power supply capability

and wire size. See Figure

2

to determine the proper

wire size and maximum wiring distance allowed.

It is important that moisture not be allowed to come in

contact with the electrical connections of the system.

The use of proper piping techniques, breathers, glands,

and seals are required to prevent water ingress and/or

maintain the explosion-proof rating.

DETECTOR WIRING PROCEDURE

iMPoRtant

Do not apply power until the wiring procedure is

complete and has been verified.

1. Determine the best mounting location for the detector

(refer to the “Detector Location” section above). If it

is determined that sensor separation is required, see

the following section for details.

2. The termination box should be electrically connected

to earth ground.

3. Figures

15

through

20

show typical wiring for various

system configurations using the Model PIR

9400

Detector. Refer to the appropriate figure as a guide

to system connection. Figure

15

shows typical wiring

for stand alone operation. Figure

16

shows typical

wiring for the PIR

9400

with Det-Tronics supplied

termination box. Figure

17

shows the termination box

terminals and calibration switch. Figure

18

shows

wiring for PIR

9400

/FlexVu UD

10

operation. Figure

19

shows typical wiring for PIR

9400

/Infiniti U

9500

Transmitter operation. Figure

20

shows a PIR

9400

wired to a DCU in an Eagle Quantum Premier system.

The PIR

9400

wiring color code is:

Red lead

=

+24

Vdc

Black lead

=

– (common)

White lead

=

4–20

mA signal output

Yellow lead*

=

Calibration input

Green lead

=

Chassis ground.

* If the calibration wire (yellow lead) is not being

used, do not connect this wire to ground. Trim

excess length and insulate wire so no shorting

can occur.

4. Check the detector wiring to ensure proper

connections, then pour the conduit seals and allow

them to dry (if conduit is being used).

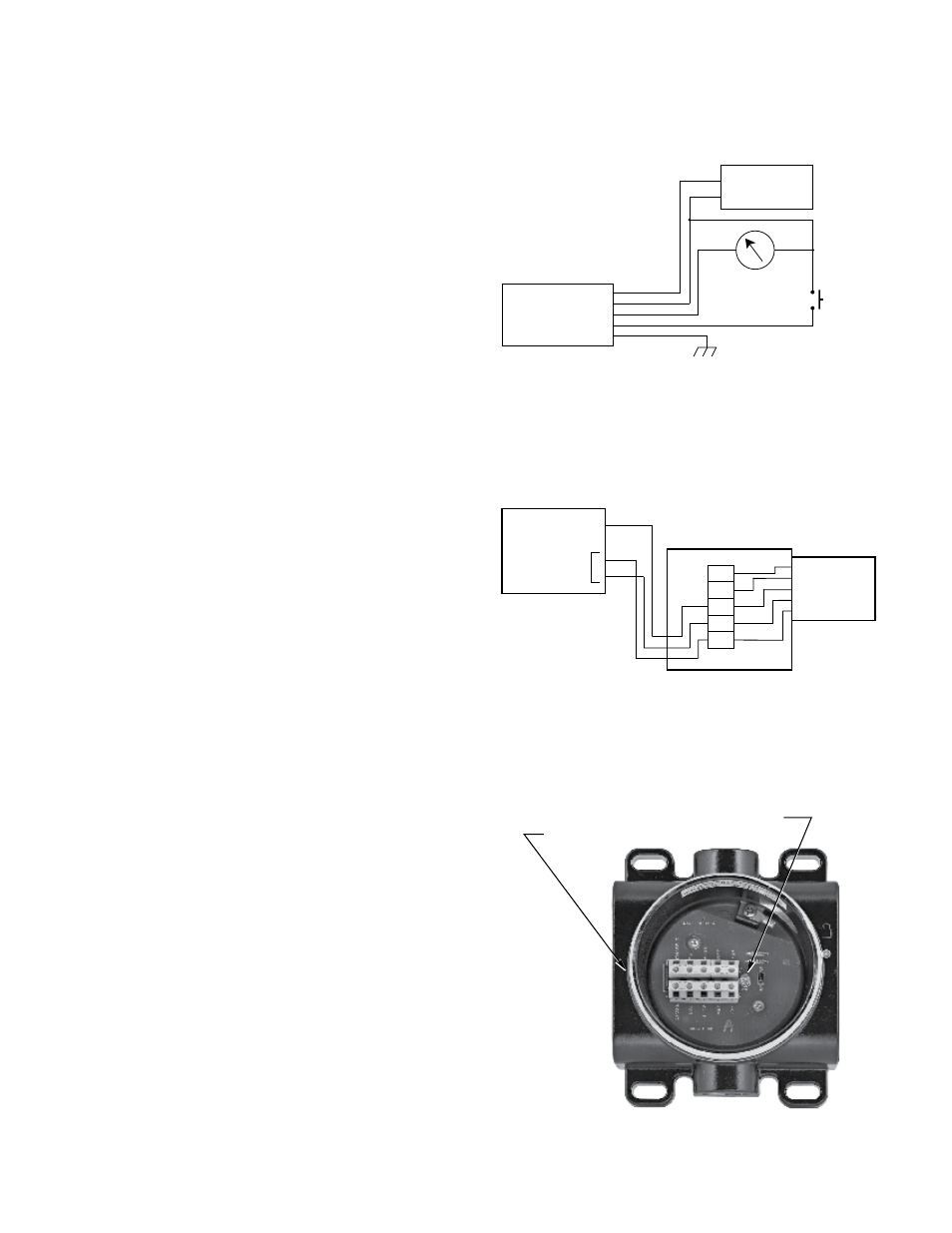

Figure 15—Typical PIR9400 Detector Wiring, Stand Alone

Configuration

–

RED

BLACK

WHITE

YELLOW

GREEN

4 TO 20 MILLIAMPERES

POINTWATCH DETECTOR

+

A1755

NOTE:

CALIBRATION PUSHBUTT0N, CURRENT METER AND POWER SUPPLY ARE NOT SUPPLIED.

+

24 VDC

POWER SUPPLY

–

+

CALIBRATE

Figure 16—Typical PIR9400 Wiring,

PIR9400 with PIRTB

+

24 VDC POWER OUT

4 TO 20 MILLIAMPERES IN

POINTWATCH

DETECTOR

DET-TRONICS TERMINATION BOX

–

+

A1756

GREEN

YELLOW

WHITE

BLACK

RED

SPARE

CAL

4 – 20

RET

+

24

CHASSIS

CAL

4 – 20

RET

+

24

Figure 17—PIRTB Terminals and Calibration Switch

CALIBRATE SWITCH

B2056

HOLD CALIBRATION MAGNET

AT OUTSIDE BASE OF JUNCTION

BOX AT THIS LOCATION

TO ACTIVATE CALIBRATION SWITCH

REMOTE LED