Recommended hepa filter burn-off process – Despatch Stackable LCC/LCD User Manual

Page 34

A

SSEMBLY

&

S

ETUP

Stackable LCC/LCD Oven

Owner’s Manual

34

Version 26

Copyright © 2010 by Despatch Industries.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

4.3.1.3. Recommended HEPA Filter Burn-Off Process

1. Locate the equipment exhaust opening where chamber air is being expelled.

a. If the oven filter is burned off in a clean area, be sure to handle the equipment

exhaust appropriately.

b. If the equipment is large and the exhaust stack is a permanent service connection,

connect the equipment and exhaust stack before the burn-off process.

c. If the equipment is small with no permanent exhaust duct required, arrange a

temporary connection out of the clean area that will handle the maximum

temperature of the equipment. Direct the smoke and odor outside, or to a highly

ventilated area.

2. Set the temperature control at the maximum process temperature.

a. Silicone: Ramp at 1.25°C/min to 260°C and soak for 48 hours.

b. Media Pack: Ramp at 1.25°C/min to 260°C and soak for 48 hours.

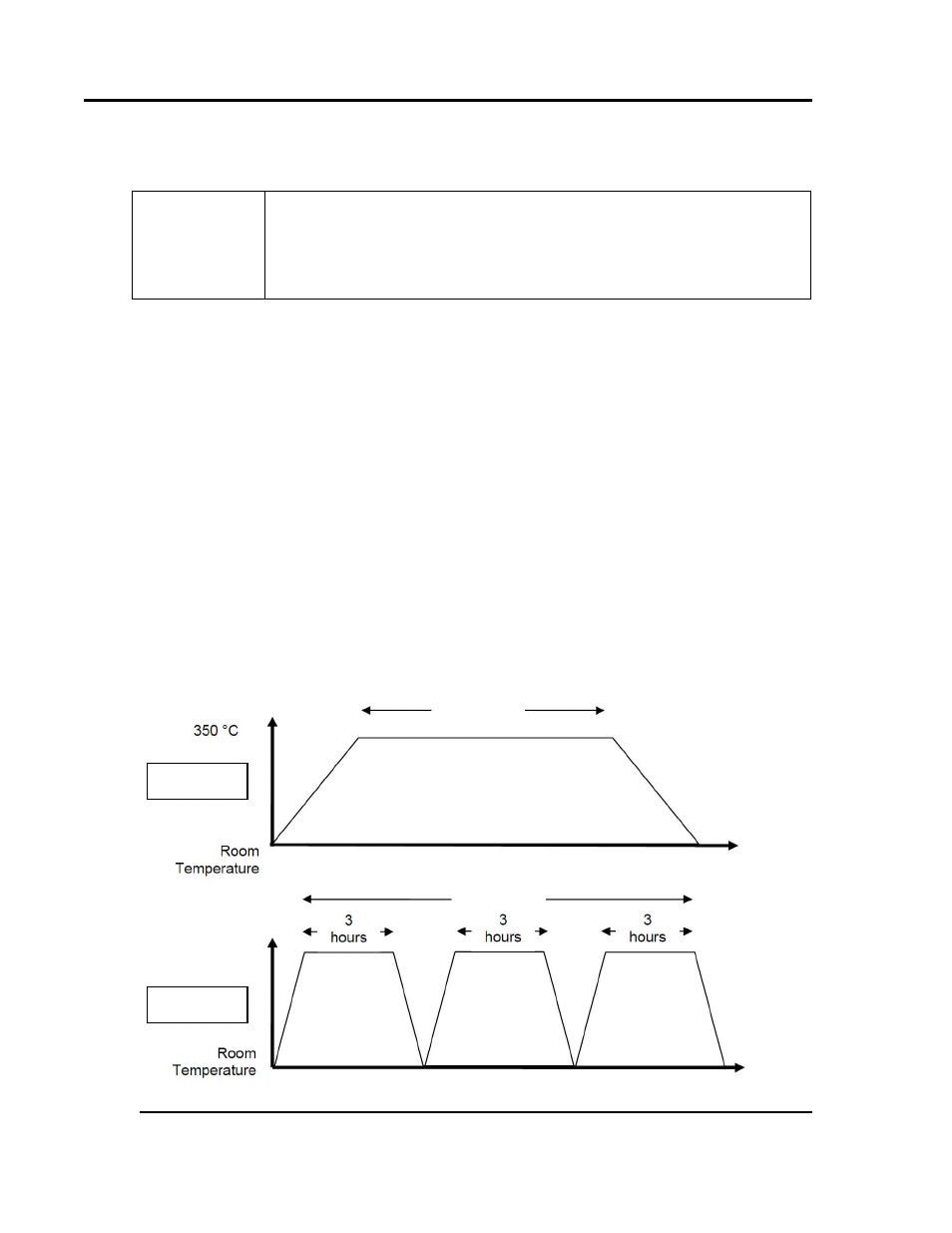

c. Termikfil (Figure 12):

i. Option 1: Ramp at 1.7°C/min (or up to 5°C/min) to 350°C and soak for 48

hours.

ii. Option 2: Ramp to process temperature and soak for three consecutive three-

hour segments over 48 hours.

LCC oven chamber temperature transitions must not exceed

1.5°C/minute to maintain class 100 chamber conditions. For ramp

rates greater than 1.5°C/minute and up to 5°C/minute, the LCD model

will maintain class 100 chamber conditions.

24 hours

24 hours

Process

Temperature

Option 1

Option 2

48 hours

48 hours

Temperature Ramp 1.7°C/min up

to 5°C/Min

Temperature

Ramp 1.7°C/

min

Figure 12. Options for Starting Termikfil 2000 Filter.