Condux APS75 Underground Pulling Trailer User Manual

Page 20

20

H. ELECTRONICS NOTE

When cleaning the machine, avoid direct spraying of water or steam on electronic

components or the control panel.

For the other periodic operations refer to the summary table for the ordinary

maintenance.

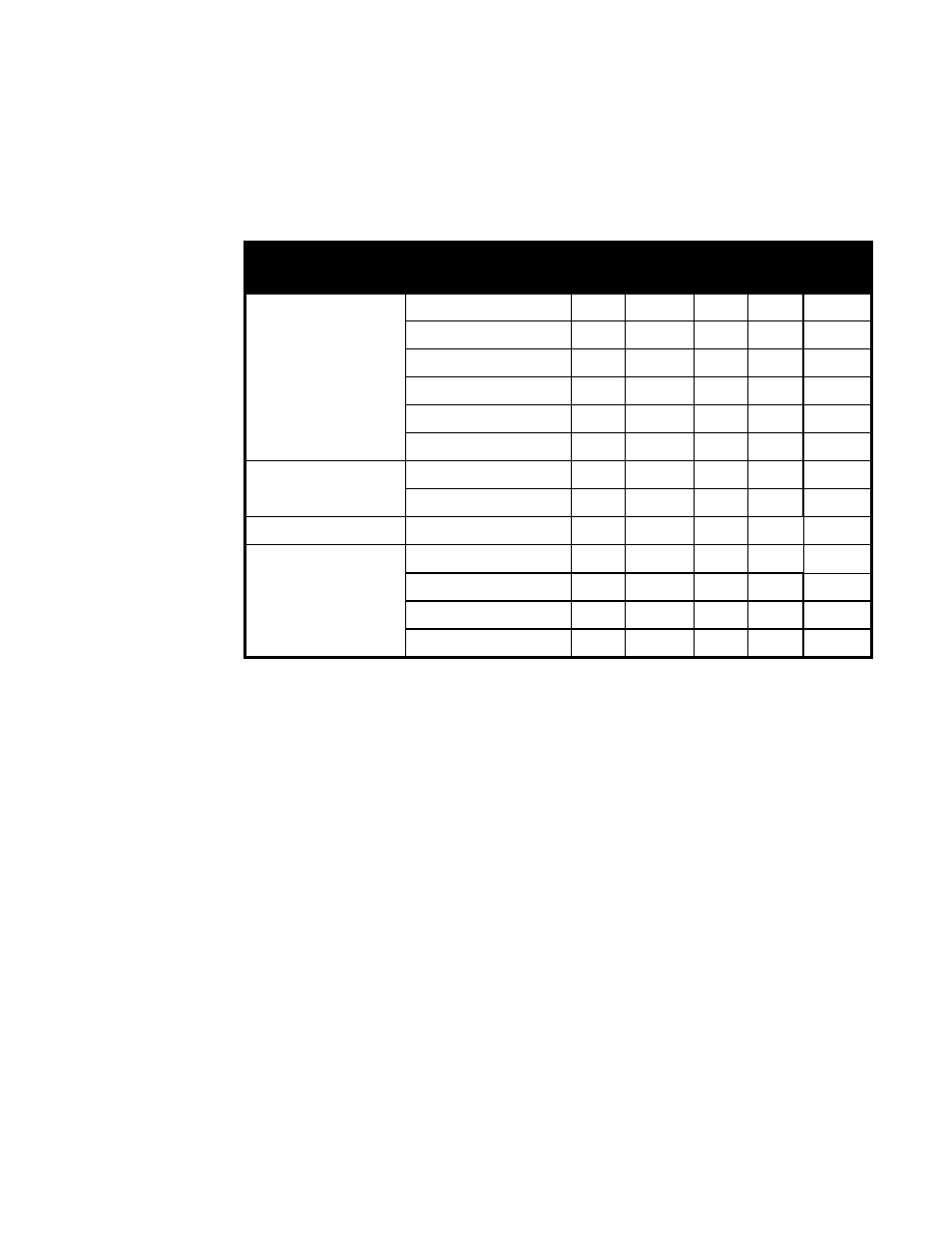

I. SUMMARY TABLE FOR ORDINARY MAINTENANCE

This table lists the recommended service intervals for the systems noted.

Part

Object

Interval

Daily

50 h

250 h 500 h 1500 h

Diesel engine

Engine oil

CL

RP

Oil filter

RP

Cooling liquid

CL

RP

Air filter

CK

RP

Fuel

CL

Fuel filter

RP

Hydraulic circuit

Hydraulic oil

CL

RP1

RP(*)

Filter

CK

RP1

RP(*)

Bull-wheel gear box

Oil

CL

RP1

RP(*)

Reel winder

Gears

GR

Chain transmission

GR

Level winder screw

GR

Pawl

GR

CK

Legend:

CL

Check the level (and possible filling up)

GR Grease

RP Replace

RP1 Replace (only for the first time)

CK Check

(*)

Or in any case every year

j. ExTENDED STORAGE

When an extended storage period is anticipated (two months or more) coat

external parts with waterproof protectant.

During the storage period, start the machine at least once every two months and

let the engine idle for approx. one hour. Do this so that oil enters the hydraulic

system and coats all gaskets, o-rings, etc.

The machine should be stored under a roof. Do not tarp the machine as excess

moisture may collect under it and cause damage to the system.

If the machine is stored for a year or more, replace the hydraulic circuit’s oil and

filters prior to startup.