Maintenance – Condux APS75 Underground Pulling Trailer User Manual

Page 18

18

Maintenance

A. GENERAL PROCEDURES

!CAUTION: Any customer repairs not authorized by the

manufacturer relieves the manufacturer of any responsibility for

any resulting damage of property or injury to personnel.

B. FLUID LEVELS

Due to safety and/or regulatory reasons, this machine may arrive without

hydraulic oil and fuel.

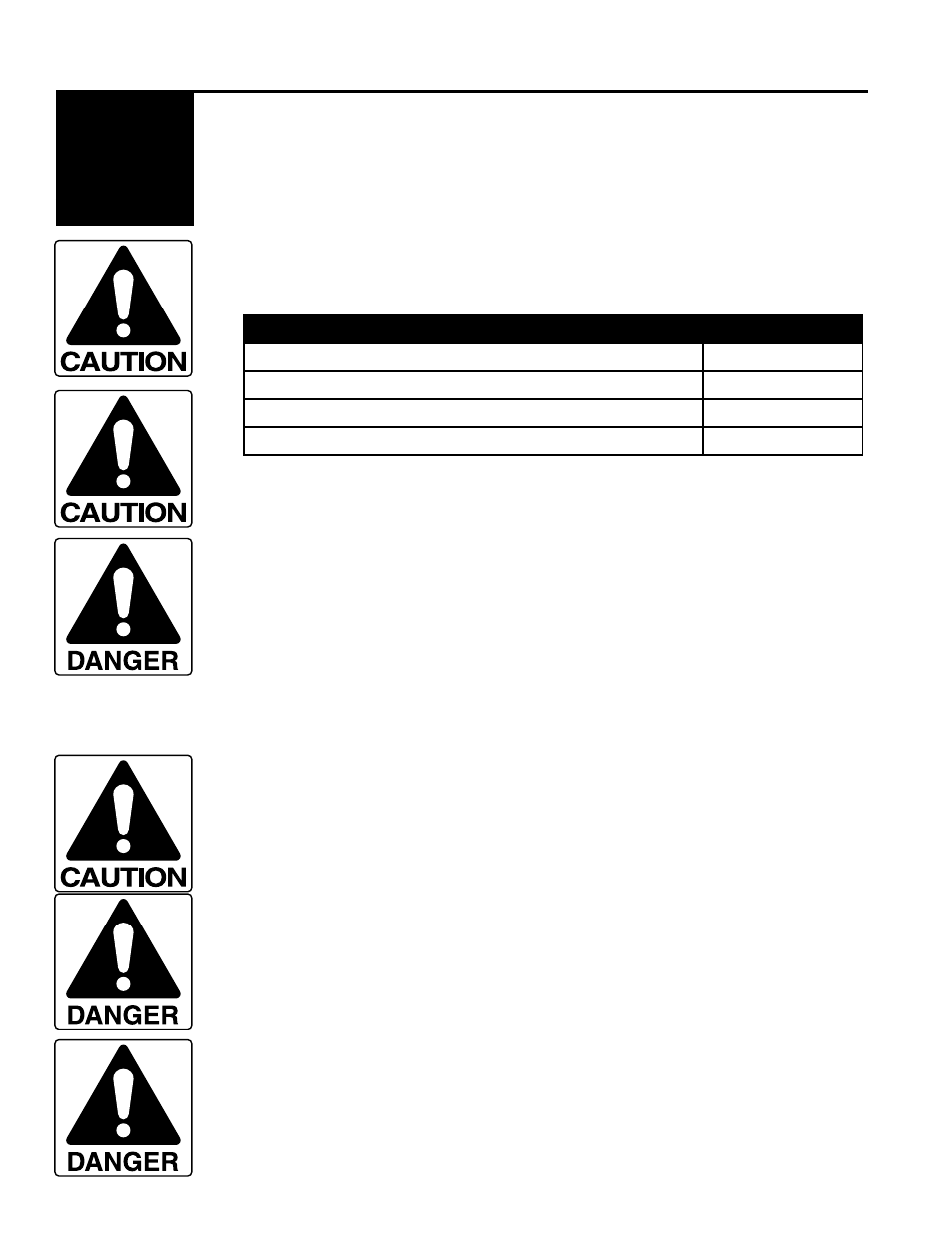

Fill the levels as per the following table:

Fluids

Quantity

Hydraulic oil level (Maintenance drawing, item 3)

79.5 l – 21.0 gal

Engine oil level (see enclosed engine booklet)

3.2 l - 3.3 qt

Fuel level (Maintenance drawing, item 6)

68 l –18 gal

Gearbox cases

1 l - 1 qt

!CAUTION: Not filling fluids to those levels specified above will

cause serious damage to system components and voids all

product warranties.

!DANGER: Purposely ingesting hydraulic liquids, fuels and

cooling liquids is potentially lethal.

C. SUGGESTED LUBRICANTS

The manufacturer tests the machine with the following oils and lubricants:

hydraulic circuit: INDOL HYDRAULIC OIL 32 (ISO VG 32).

Alternates must be chosen from the enclosed table “SUGGESTED

LUBRICANTS”. It is possible to use different products, but they must have the

same characteristics and ISO specifications.

!CAUTION: The use of lubricants not in conformity with the

technical specifications indicated in the referenced table can

seriously damage the machine, its components and voids all

product warranties.

!DANGER: Let the engine cool prior to performing any

maintenance, or before refueling.

D. HYDRAULIC CIRCUIT MAINTENANCE

Change the hydraulic oil after 500 working hours, then every 1500 hours

(or at least annually).

To drain the hydraulic oil remove the hydraulic tank’s drain plug

(Maintenance drawing, item 2).

!DANGER: Allow the hydraulic oil to completely cool before

removing it. Always use suitable safety gear (gloves, etc.).

5.

8.