Process description – Clarus Environmental Fusion Series Treatment Systems 2800/3200/3600/4000 User Manual

Page 3

3

© Copyright 2013. All rights reserved.

Back-Wash

Recirculation

Sedimentation Chamber

Anaerobic Chamber

Aeration Chamber

Storage Chamber

Effluent

Inflow

1

2

3

4

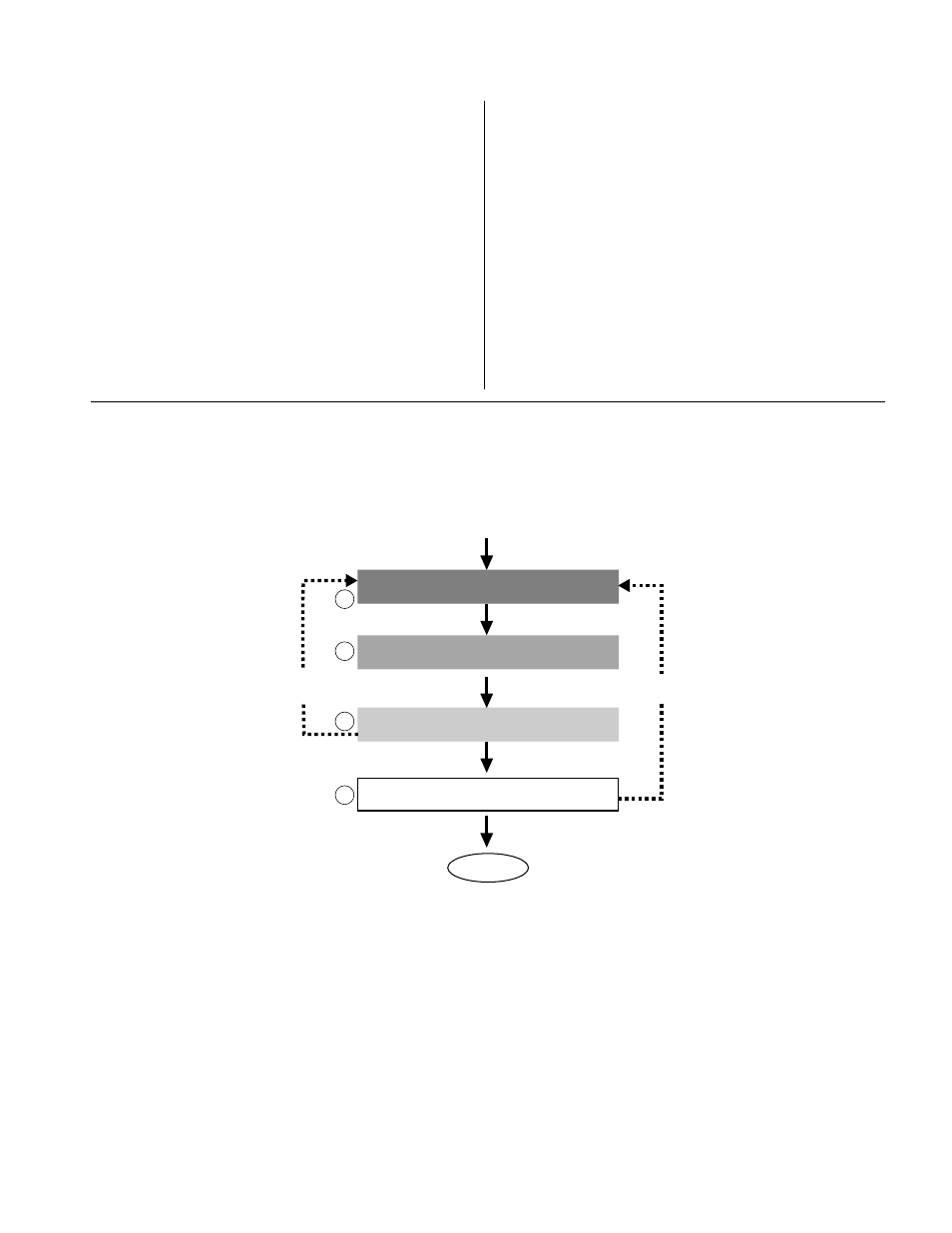

Figure 3 - Treatment Flow of the Fusion

®

System.

PROCESS DESCRIPTION

1. Sedimentation Chamber

This chamber is designed to physically separate solids from the

incoming water. Scum is the floating material and sludge is the

material that has settled at the bottom.

2. Anaerobic Chamber

This chamber contains a spherical skeleton-type of filter media,

4.3 inch diameter (109 mm). Through bacterial growth processes

on the surface of the filter media, biological anaerobic treatment

thrives while suspended solids are captured. Furthermore,

the microorganisms in this chamber convert nitrates in the

recirculated water returning from the aerobic chamber to

gaseous nitrogen. The gaseous nitrogen then escapes to the

atmosphere.

3. Aeration Chamber

The aeration chamber consists of an aerated upper section and

a filter media lower section. The chamber is filled with hollow,

cylindrical filter media 0.6 inch diameter (15 mm) and 0.55 inches

long (14 mm). Biological treatment takes place on the filter

media surface. Aeration is continuous. Residual suspended

solids are captured by the filter media circulating in this section.

During normal operation, a recirculation line transfers water back

to the sedimentation chamber by way of an air lift pump.

The filter media in the aeration chamber are backwashed

regularly (twice a day, 5 or 10 minute cycle) by the backwash

system located at the bottom of the chamber. The accumulated

sludge is transferred by an air lift pump back into the

sedimentation chamber for further digestion.

4. Storage Chamber

This chamber is designed to temporarily store treated water

exiting the aeration chamber. This treated water is ready for

discharge.