Fusion, Operation and maintenance, continued, System diagram – Clarus Environmental Fusion Series Treatment Systems 2800/3200/3600/4000 User Manual

Page 14: Aeration chamber cleaning

14

1.

Aeration.

The aeration system must be flushed every maintenance

visit. There are two flushing methods; (A) Air flushing

and (B) Water flushing. Air flushing must be done every

maintenance visit. Water flushing must be done if there is

a sign of clogging in the Aeration Chamber (e.g. abnormal

increase in recirculation flow).

(A) Air flushing procedure:

• Close gray recirculation valve (2) all the way. (0%)

• Rotate blue aeration valve (1) back and forth from the

0% to the 100% position several times to flush.

• Set valves (1) and (2) back to the appropriate positions.

(See Recirculation Flow Adjustment, pg. 10)

(B) Water flushing procedure: (See Fig. 20)

• Make sure that the blower is off.

• Close valve (2) all the way.

• Connect a water line to the aeration line after the

switching valve, as shown in Fig. 20.

• Gradually open the water faucet and

introduce water into the system.

• Rotate valve (1) back and forth from the

0% to the 100% position several times

to flush.

• Turn off the water, remove the water line,

and reconnect the airline to the blower.

• Set valves (1) and (2) back to the

appropriate positions.

(See Recirculation Flow Adjustment, pg. 10)

(C) Cleaning the recirculation line:

• Open the gray recirculation valve (2) to 100%.

• Flush water through the recirculation line for several seconds.

• Turn off the recirculation by rotating the gray valve (2) to 0%.

• Make sure that the blower is off. Allow the system to relax

for a few seconds.

• Repeat this cleaning method three times.

• A hose or brush can also be used to clean the

recirculation line. See Figure 21.

• Reset the gray valve (2) to its original position.

FAUCET

BACKFLOW

PREVENTER

WATER

HOSE

CLAMP

TO TREATMENT UNIT

BLOWER

EXISTING

AIR LINE

.

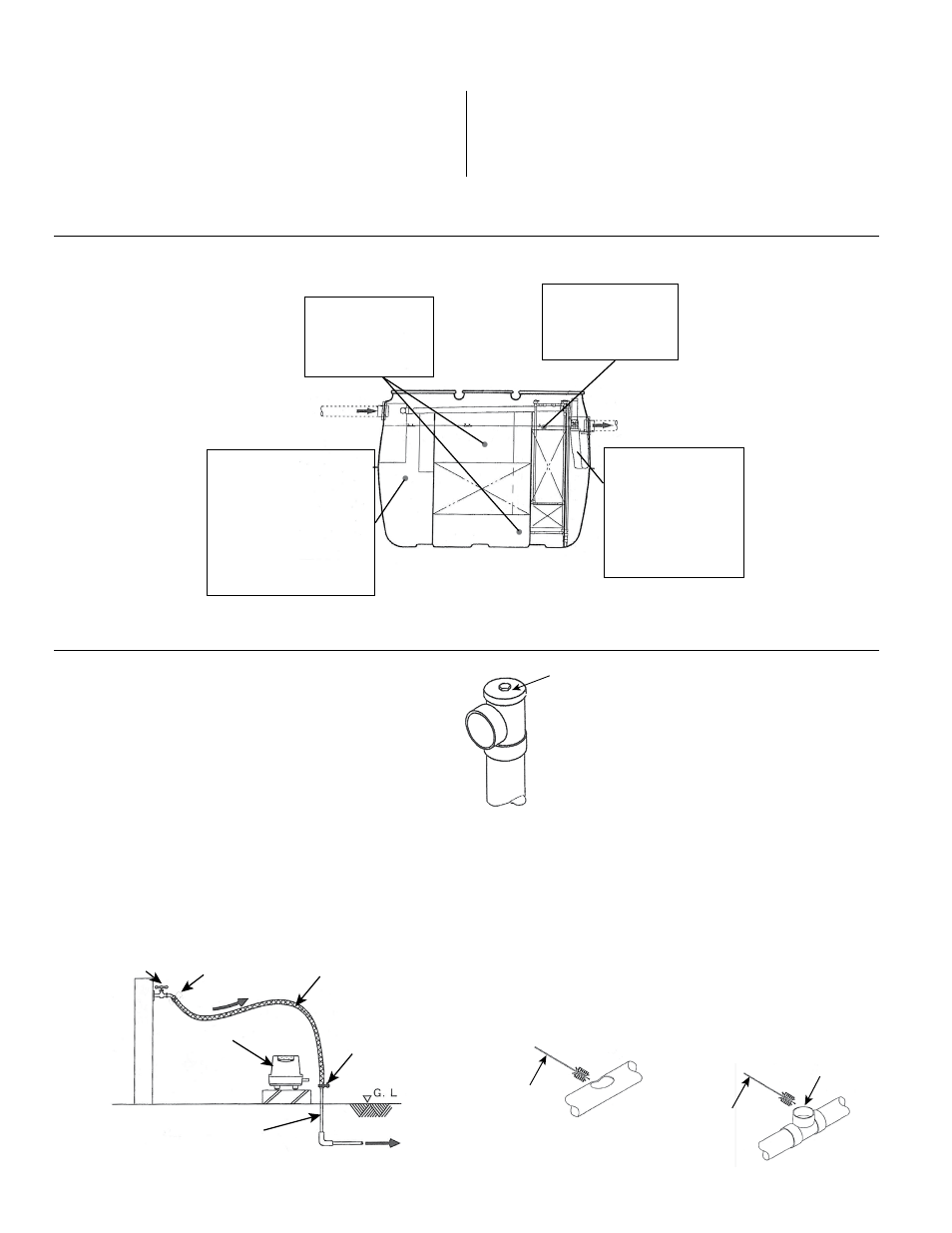

SYSTEM DIAGRAM

© Copyright 2013. All rights reserved.

BRUSH

CLEAN OUT

BRUSH

BRUSH

CLEAN OUT

BRUSH

< 30 mg/L. If this test is desired, it should be conducted

with test strips suitable for the expected concentration.

Adjustments should be based on water quality in the

clean water storage chamber.

5. Transparency – Typically < 15 cm. Adjustments should be

based on water quality in the clean water storage chamber.

6. Dissolved oxygen – Typically < 0.5 mg/L.

7. Temperature – varies with system location.

FUSION

®

OPERATION AND MAINTENANCE, continued

AERATION CHAMBER CLEANING

ANAEROBIC CHAMBER

1. Scum

2. Sludge accumulation

3. Abnormal water level

AERATION CHAMBER

1. Aeration

2. Foam formation

3. Abnormal water level

STORAGE CHAMBER

1. Scum

2. Sludge accumulation

3. Formation of micro

organisms

4. Transparency

5. Nitrite

6. pH

SEDIMENTATION CHAMBER

1. Inflow pipe

2. Odor with manhole closed

3. Scum

4. Sludge accumulation

5. Abnormal water level

6. Insects

7. Excess amount of oil and fat

8. Trash accumulation

Figure 19

Figure 21

Figure 18

Refer to sections on the following pages for detailed maintenance item descriptions.

Figure 20

CLEAN OUT

AIR LIFT

PUMP