Clarus Environmental Recirculating Media Filters User Manual

Page 10

10

© Copyright 2011. All rights reserved.

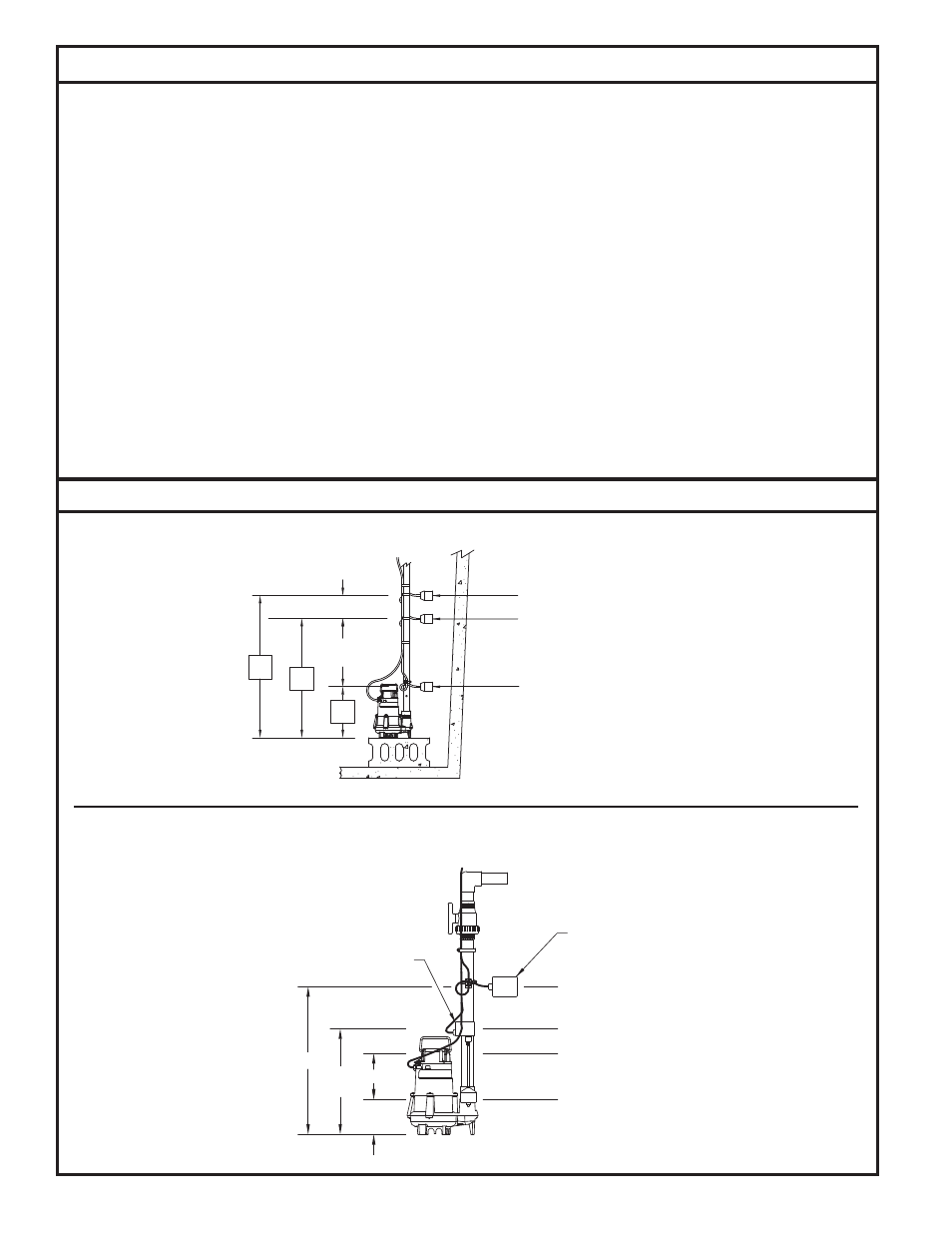

LOW LEVEL CUTOUT EVEN

WITH TOP OF PUMP

TIMER OVERRIDE

HIGH WATER ALARM

15" MIN.

6" MIN.

Performing a good system start-up is crucial to having a long lasting system that will be trouble free. A trained, qualified technician that

understands the system’s mechanical and electrical operation must do the system start-up. The system start-up report should be completed

in coordination with the installing contractor, start-up technician, health department agent, homeowner, and the engineer. An installation and

start-up checklist (CL0063) is included to aid the system start-up procedure.

The timed dosing panel should be set up to dose 96 times per day. Consult the engineering site plan and/or control panel instructions to aid

in the set up. Recirculation ratio must be taken into account when adjusting for the daily design flow rate.

The homeowner and maintenance contract personnel must receive a copy of the following documents:

1. Recirculating Media Filter literature sheet (CL0062).

2. Recirculating Media Filter Owner’s Manual (CL0064).

3. Control Panel Wiring Diagram.

4. Control Panel Installation Instructions and Operation/Troubleshooting Manual.

5. Completed Start-Up Report.

6. Tru-Flow

®

Splitter System Installation Instructions (CL0075).

7. Submersible Pump Installation Instructions (FM0447).

8. WW1 Filter owner's manual (CL0040).

Record the float settings of the dose tank and recirculation basin on the drawings below.

System Start-up

Typical Float Settings For Zoeller Model N153 Pumps

SK2147

MEDIA FILTER DOSE TANK

SK2153

PUMP DISCHARGE BASIN

(located in media filter on pump discharge systems)

ON LEVEL

OFF LEVEL

ALARM FLOAT

TETHER HEIGHT

5"

6 1/2"

15"

VERTICAL FLOAT SWITCH

TETHER HEIGHT

21"