Voltmeter, Oil pressure, vacuum & boost gauges – Auto Meter 2312 User Manual

Page 3

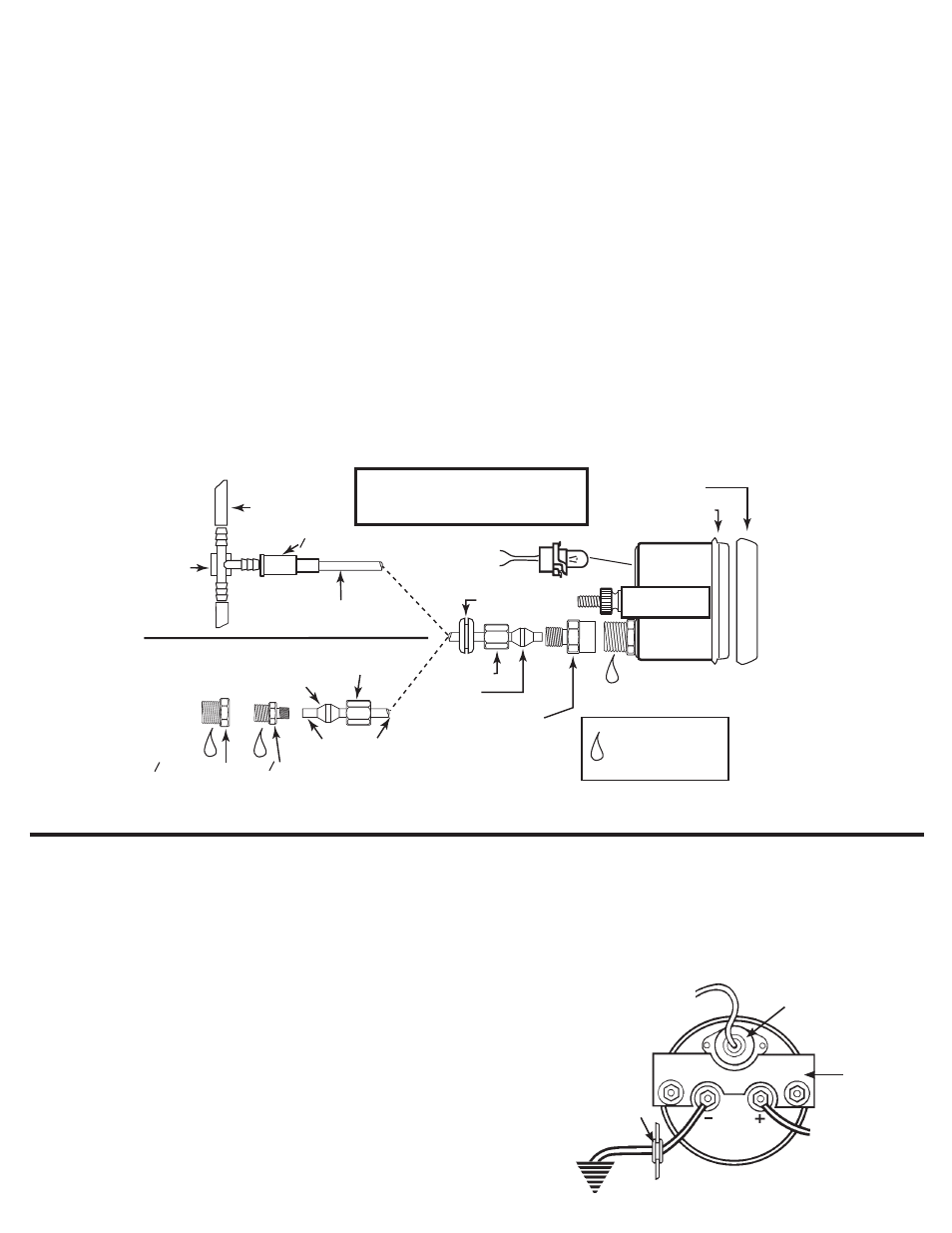

ADAPTeR

USe TeFLON SeALINg

TAPe OR SeALINg

COMPOUND ON

PIPe THReADS

4

"

NPT ADAPTeR

8

"

NPT ADAPTeR

FOR PReSSURe

gAUgeS ONLY

FOR VACUUM

AND BOOST

gAUgeS ONLY

VACUUM HOSe

T-FITTINg

FeRRULe

SeALINg NUT

CONNeCT TO

12V LIgHTINg

CONNeCT TO

gOOD gROUND

gROMMeT

NYLON TUBINg

FeRRULe

SeALINg NUT

8

"

CONNeCTOR

1

NYLON TUBINg

1

1

SNAP-ON

BeZeL

BLACK

BeZeL

U BRACKeT

Voltmeter

MODeL 2319

1. Disconnect the negative (-) battery cable. (Wear safety glasses)

2. Auto Meter wire kit No. 2217 (18-gage) is recommended. Route one length

through firewall using grommet. Attach one end to the left hand terminal (-)

on back of gauge and the opposite end to a good engine ground.

3. Attach one length of wire to the right hand terminal (+) on back of gauge

and opposite end to 12 volt terminal on ignition switch or to any 12 volt

source.

4. Snap-in light socket assembly and connect to dash lighting circuit or to

other 12 volt source. If dash is metal, a ground connection for light is made

when gauge is mounted with brackets provided. If dash is non-metallic (or

if gauge is cup mounted), a separate ground wire must be connected from

gauge case to a good ground.

5. Reconnect negative (-) battery cable.

To 12V Dash

Lighting Circuit

To 12V Terminal

On Ignition

Switch Or Other

12V Source

Ground To

Engine

Light (installed)

U-Bracket

Grommet

Oil Pressure, Vacuum & Boost gauges

1. Gauge can be mounted in 2

5

⁄

8

” dia. dashboard hole in Auto

Meter mounting panels.

2. Drill a

3

⁄

8

” dia. hole and install rubber grommet where pressure

or vacuum line passes through sheet metal, such as firewall.

3. BOOST, OIL PRESSURE, and VACUUM gauges require

attaching nylon pressure line or braided stainless steel

pressure line to port on back of gauge.

For BOOST, connect line to a manifold vacuum/pressure line

using the fittings provided with the gauge and pressure line kits.

For OIL PRESSURE, connect line to the appropriate pressure

port on engine.

For VACUUM, connect line to a manifold vacuum line using the

fittings provided with the gauge and pressure line kits.

4. To help prevent leaks, be sure the end of nylon tubing is cut

cleanly and straight. Slide compression nut onto tubing with

threads toward end of tubing. Next, slide ferrule onto end of

tubing, leaving

3

⁄

16

” between ferrule and end of tubing. Insert

end of tubing into the

1

⁄

8

” NPT male adaptor. Apply pressure

to maintain constant bond between end of tubing and inside

of adaptor. Slide ferrule into the adaptor then compression

nut. Tighten compression nut with

3

⁄

8

” open-end wrench, while

holding adaptor firm with

7

⁄

16

” open-end wrench. This should

form a tight seal between end of tubing and inside of adaptor.

To make sure it is a snug fit, tug lightly on nylon tubing to make

sure it doesn’t come out.

NOTe: Use teflon sealing tape or sealing compound to assure

proper seal on all pipe thread joints (NPTF).

5. Make sure line is free from hazard of moving parts or hot engine

components. Where potential hazard exists, braided stainless

steel pressure line is recommended.

6. Snap in light socket assembly and connect to dash lighting or

other 12 volt light source. If dash is metal, a ground connection

for light is made when gauge is mounted with brackets

provided. If dash is non-metallic (or if gauge is cup mounted), a

separate ground wire must be connected from gauge case stud

to a good ground.

7. Wrap a clean rag around fittings on back of oil pressure gauge

and place a pan on floor under them to protect vehicle interior

from potential oil leaking. Start engine and run for 30 seconds.

Shut engine off and check rag or leaks If none appear, start

engine again and visually check all connections for leaks.

MODeLS 2310, 2312, 2317

NOTe: NYLON PRESSURE TUBING

MUST PROTRUDE OUT FERRULE

END. (APPROx.

1

⁄

16

” TO

3

⁄

16

”