Warning, Before you begin – AMMCO 7700 Drum and Disc Brake lathe User Manual

Page 5

AMMCO Drum & Disc Brake Lathes • 1

Before You Begin

Receiving

The shipment should be thoroughly inspected as

soon as it is received. The signed bill of lading is

acknowledgement by the carrier of receipt in good con-

dition of shipment covered by our invoice.

If any of the goods called for on this bill of lading are

shorted or damaged, do not accept them until the car-

rier makes a notation on the freight bill of the shorted

or damaged goods. Do this for your own protection.

NOTIFY THE CARRIER AT ONCE if any hidden loss or

damage is discovered after receipt and request the car-

rier to make an inspection. If the carrier will not do so,

prepare a signed statement to the effect that you have

notified the carrier (on a specific date) and that the car-

rier has failed to comply with your request.

IT IS DIFFICULT TO COLLECT FOR LOSS OR DAM-

AGE AFTER YOU HAVE GIVEN THE CARRIER A

CLEAR RECEIPT.

File your claim with the carrier promptly. Support your

claim with copies of the bill of lading, freight bill,

invoice, and photographs, if available.

Although AMMCO’ s responsibility ceases upon

delivery of the shipment to the carrier, we will gladly

assist in tracing lost shipments. Our willingness to

assist in every possible manner does not make

AMMCO responsible for collection of claims or

replacement of lost or damaged materials. Shipping

damage claims will not be handled under warranty.

Electrical Requirements

The lathe must be properly grounded to protect the

operator from shock. The lathe is equipped with an

approved 3-conductor cord and a 3-prong grounding

type plug to fit the proper grounding-type receptacle.

Should an extension cord be required, use 3-conductor

cords with 3-prong grounding plug and 3-prong ground-

ing receptacle properly rated to handle this electrical

power tool only. Do not modify a cord or plug to match

a receptacle; have a qualified electrician install an

appropriate outlet to match the lathe requirements.

Repair or replace any worn or damaged power cords

immediately.

Verify that the lathe plug and grounding-type recepta-

cle match as shown in Figure 1.

Figure 1 - Power Cord Plug and Receptacle Types

Installation

1.

Assemble bench according to the instructions pro-

vided. Tighten all fasteners securely.

2.

After assembly, the bench should be leveled and

may be bolted down with 3/8 or 7/16 inch bolts or lag

screws.

3.

Unbolt the lathe from the shipping pallet. Lift the

lathe onto the bench.

4.

Bolt the lathe to the bench with the hardware pro-

vided. Tighten fasteners securely.

5.

Remove any packing materials and protective

wrapping from the lathe and components.

6.

Make sure lathe is turned off. Plug lathe into a

properly installed and grounded outlet that matches the

lathe plug.

7

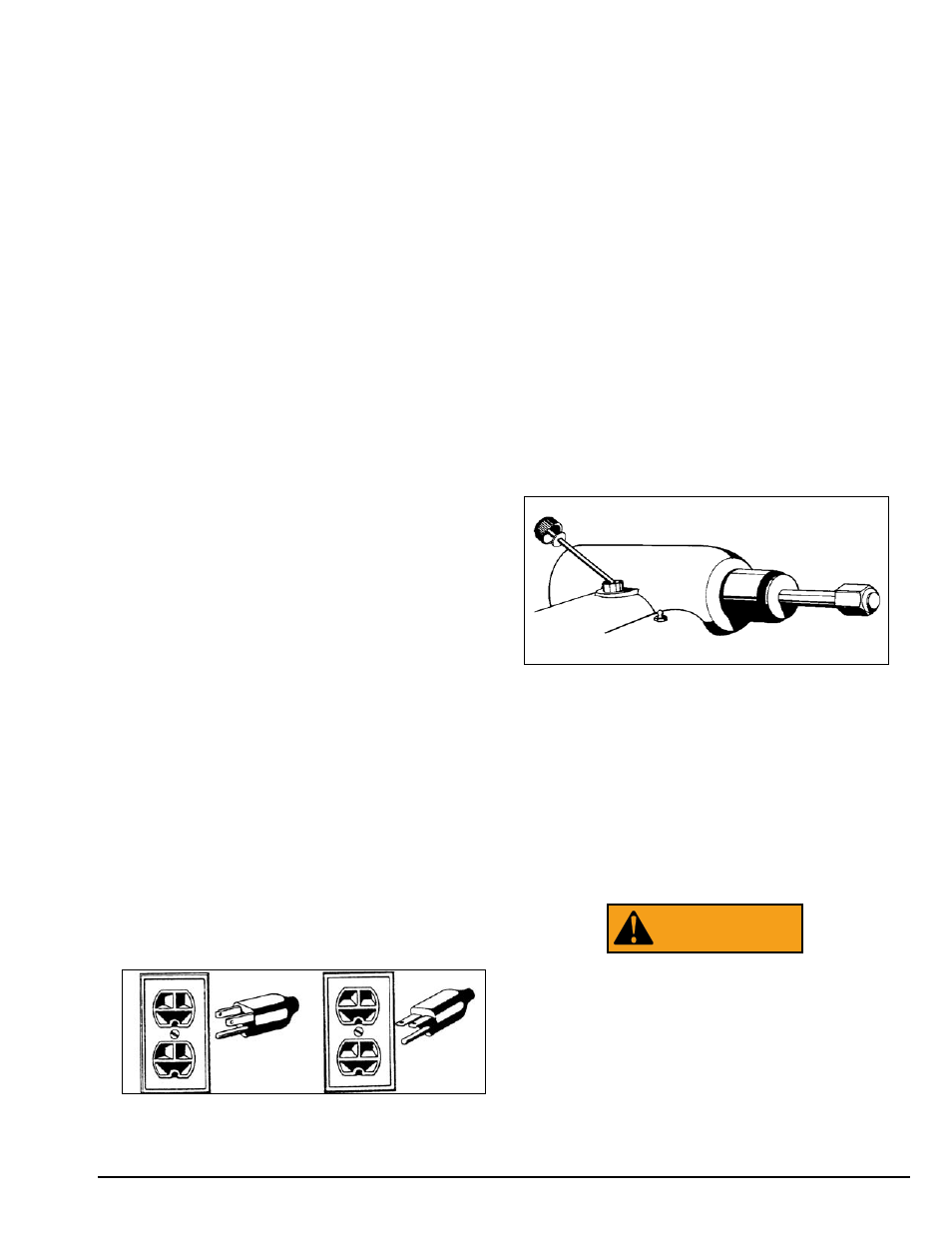

. Remove the shipping plug, insert the oil dipstick,

and check oil level. The lathe is shipped with the cor-

rect amount and type of oil. Add oil as necessary to

reach the correct mark on the dipstick. Use only EP-80-

90 gear oil. Oil level should be checked often.

Figure 2 – Check oil level

8.

Clear the area and turn lathe on. Check for proper

operation (motor and spindle rotation).

Preparation for Use

1

. Inspect all adapters and accessories for burrs,

nicks, or other damage.

2.

Clean accessories with a vaporizing solvent.

3.

Apply a light film of oil to all adapters to protect

their machined surfaces from rust. Refer to the main-

tenance section for more information.

There is a circuit breaker located on the elec-

trical panel to prevent damage to the lathe

in the event the motor is overloaded. Move

the switch to the off position and correct

overloading situation before re-setting cir-

cuit breaker. Serious personnal injury could

result if circuit breaker is re-set while lathe is

still on.

WARNING

115 VAC

230 VAC