Caution, Basic operation – AMMCO 7700 Drum and Disc Brake lathe User Manual

Page 8

4 • AMMCO Drum & Disc Brake Lathes

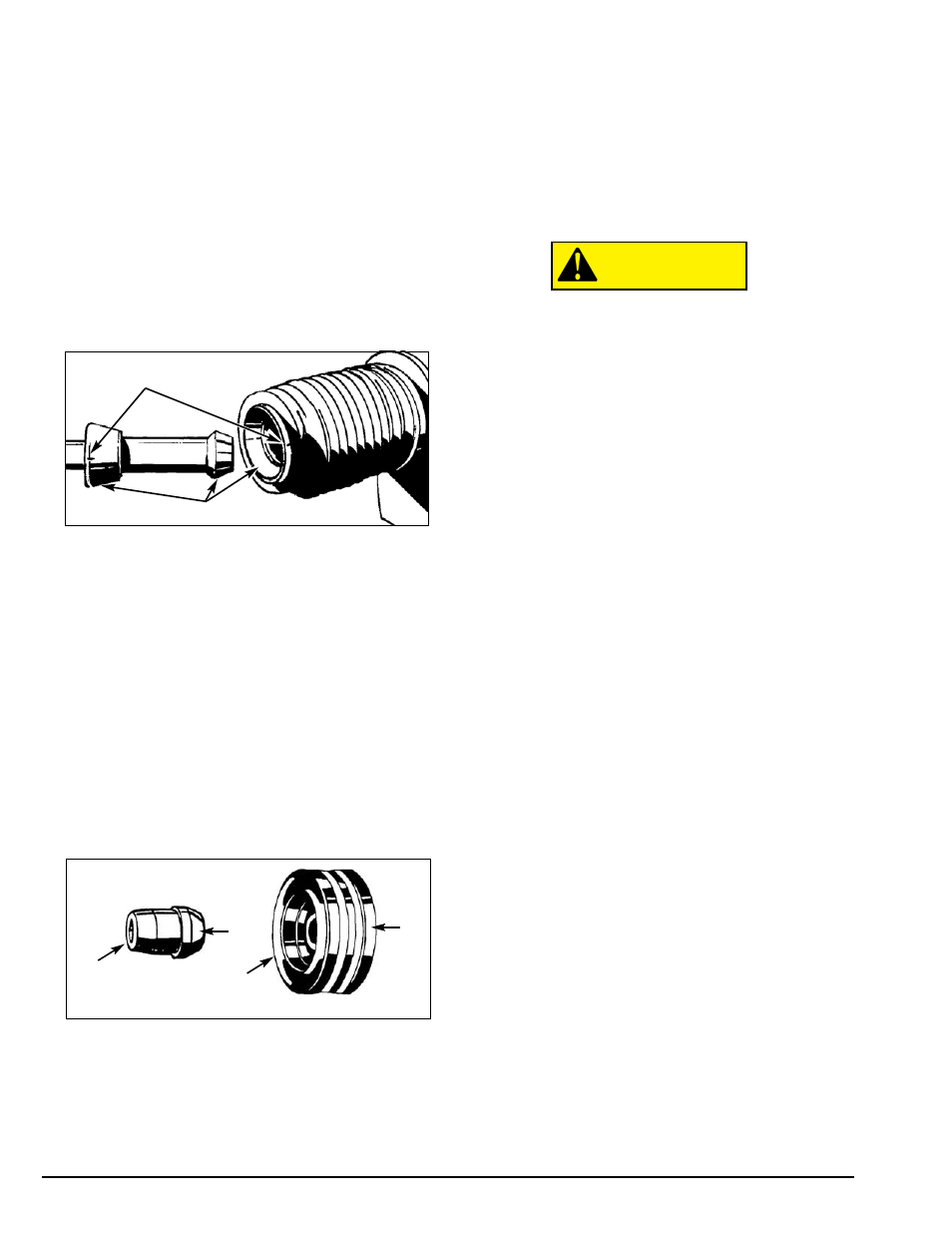

Arbor Installation

The 1” arbor shipped with the lathe has been care-

fully matched to the lathe during final assembly and

testing. Witness marks have been etched onto the

arbor and the spindle for precise, repeatable alignment.

The witness marks must be carefully aligned when

installing the arbor (Figure 3). A true-running arbor is

essential to professional quality brake drum and rotor

reconditioning.

1.

Locate the witness marks on the arbor and the

spindle.

Figure 3 – Align witness marks during arbor installation

2.

Insert the arbor into the spindle making sure the

witness marks are aligned.

3.

Tighten the drawbar (located at the rear of the

spindle) to pull the hardened and ground tapers of the

arbor into the matching seats in the spindle.

Adapters

Important: Although the adapters, arbor, and spindle

are made of top grade steel and are turned, hardened,

and precision ground to close tolerances, great care

should be taken in their use, handling, and storage.

Even the smallest nick, scratch, or loose chip on the

machined mating surfaces can cause incorrect rotor

mounting alignment. This will cause inaccurate machin-

ing.

Figure 4 – Use care to avoid damaging mating surfaces

Always inspect the surface, face, and seating tapers

of each part before use. Wipe each part clean before

and after using it. Carefully correct any flaw with a fine

stone. If damage cannot be corrected, replace the part.

Basic Operation

To completely understand drum and rotor turning you

must have a knowledge of the lathe itself.

Spindle

The spindle is a motor driven shaft that turns the

arbor upon which the brake drum or rotor is mounted.

By turning the drum and holding a cutting tool against

the inner braking surface, metal can be removed.

Do not try to move any feed levers or dials

without the drive motor running. Damage

may occur to the gear trains.

Spindle Feed

By operating the spindle feed lever, the spindle will

move the mounted brake drum to the left. This feeds

the braking surface across the cutting tool as the drum

moves away from the tool. Spindle feed may also be

done manually using the spindle feed handwheel.

Spindle feed refers to the distance the spindle is

pulled per revolution. This speed is adjustable on all

models except the 7500:

Important: Spindle feed must be adjusted with the

lathe running.

1.

Rotate the spindle feed dial to the desired feed

rate. The rate is adjustable to any point between

0.002” (0.05 mm) and 0.020” (0.50 mm).

Spindle Speed

Spindle speed is measured in RPMs and is adjustable.

Refer to the specifications listed on page 4 for the RPM

rating of each grove on the V-belt pulley for each

model.

Spindle Speed Adjustment

This V-belt adjustment must be made with the lathe

off.

1.

Release the belt tension by moving the V-belt

adjusting lever to the right (clockwise).

2.

Move the belt to the pulley groove that will give

the correct spindle speed for the cut to be taken.

3.

Reapply tension to the V-belt by moving the

adjusting lever back to the operating position.

Cross Feed

The cross feed draws the tool bit across the face of a

brake rotor or flywheel when the cross feed drive is

engaged (models 4000, 4100, and 7500). The cross

feed may also be operated manually using the cross

feed handwheel (all models).

Feed speed refers to the thousandths of an inch the

cutting tools move per revolution of the spindle. The

CAUTION

Arbor

Keep the arbor tapers and seats clean

Witness Marks

Typical Inner & Outer Adapters

Seating Tapers

Machined Surfaces